e3d TC coupler motor is not moving and homing C has no errors?

-

I am not sure that "General discussion" is the correct place. I apologize in advance for this

So I home the x >y >z> then I home the C axis no errors but the motors does not rotate at all.

Also when I try the unlock or lock coupler macro nothing moves. What am missing?

Here is my config file... I know my 3-axis z is not set up nor are my tools plugged in but please ignore that. (unless this is why the coupler motor is not moving at all)

; Configuration file for Duet WiFi (firmware version 3.4.0) ; executed by the firmware on start-up ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; General Global Preferences and critical Drive Configuration Section - These must come before all else. ;M80 ; ATX ON G4 P2000 ; Hold your Horses. Add a little time to allow things to settle and complete. G90 ; send absolute coordinates... M83 ; ...but relative extruder moves G21 ; Set units to Millimeters M550 P"Cube 3D Printer Duet" ; set printer name - change this to whatever you'd like M584 X1 Y0 Z7:8:9 C2 E3:4:5:6 ; set drive mapping to each axis --- *EDP* - 1 The "Z2:5:6" would be ; Note the M567 commage later. These are related and connected. This command must always come before a number of other commands. Refer to https://duet3d.dozuki.com/Wiki/RepRapFirmware_3_overview M575 P1 S1 B57600 ; Start Serial Com with PanelDue M669 K1 ; Select CoreXY mode ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Network Configuration Section M552 S1 ; enable network M587 S"DAHWIFI" P"Nandina95" ; Add a WiFi host network to the remembered list. M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ;Stall Detection ;M915 Z S6 F0 H200 R3 ; Z axis ;M915 E S6 F0 H400 R3 ; Extruder ;M915 X Y S3 F0 H400 R3 ; X / Y Axes, S=lower values more sensitive R3=pause&rehome.g&resume print ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Drives - Establish the Drive designation and the direction they turn. ; Validate these settings as a first step. ; If your wiring differs, you can fix the direction here instead of rewiring. M569 P0 S0 ; X axis M569 P1 S1 ; Y axis M569 P2 S1 ; Coupler MAY HAVE TO INVERT TO S1!!! M569 P3 S1 ; Tool 1 Extruder M569 P4 S1 ; Tool 2 Extruder M569 P5 S0 ; Tool 3 Extruder M569 P6 S0 ; Tool 4 Extruder M569 P7 S0 ; z-axis: mid left M569 P8 S0 ; z-axis: front right M569 P9 S0 ; z-axis: back right M671 X-64:206:206 Y60:-25:120 S15 ; Set up three Z-axis location ; *EDP* - 1 This tells the Duet the physical location of the center of the leadscrews. ; for reference the order/sequence of defined coordinate positions MUST correspond to ; the order of axis drives that was specified above in the M584 gcode 1 - left, 2 - front right and 3 - rear right M92 X200.00 Y200.00 Z200.00 C200 E562:562:562:562 ; set steps per mm, based on using 1.8 degree steppers for X/Y/Z M350 E16:16:16:16 I1 ; configure micro-stepping with interpolation M350 C16 I0 M350 X16 Y16 Z16 I1 M566 X400.00 Y400.00 Z8.00 C2 E200:200:200:200 ; set maximum instantaneous speed changes (mm/min) M203 X35000.00 Y35000.00 Z1200.00 C10000 E5000:5000:5000:5000 ; set maximum speeds (mm/min) *EDP* M201 X3000.00 Y3000.00 Z100.00 C500 E2500:2500:2500:2500 ; set accelerations (mm/s^2) ;M204 P2000 T4000 ; set printing and travel acceleration M906 X1300 Y1300 Z800 C500 E500:500:500:500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Axis Limits NEED CHANGING FOR TC. CONSERVATIVE GUESS NOW for XY M208 X-14 Y0 Z0 S1 ; set axis minima M208 X330 Y265 Z350 S0 ; set axis maxima ;--> print size: 300x300x400 ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Endstops M574 Y1 P"xstop" ; X min active low endstop switch M574 X1 P"ystop" ; Y max active low endstop switch Was S0 before TC M574 Z0 ; No z endstop M574 C1 S3 ; Stall detect coupler at low end of its range ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ;Z-probe M558 P8 C"zstop" H3 F120 I0 T20000 ; set Z probe type to switch IF WORKS, CHANGE TO F360 I0 T20000. MAYBE CHANGE I0 TO C"!..." TO INVERT? G31 P200 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height Z0.9 seems to be a bit too close for pla ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; Stall detection ;M915 C S6 F0 H200 R0 ; Coupler ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Configure Heaters and Sensors ; ; Bed Heater: M308 S0 P"bedtemp" Y"thermistor" A"Bed Heater" T100000 B3950 ; Configure bed temperature sensor - M950 H0 C"bedheat" T0 ; Define heater 0 (bed heater) - bind the bed_heat pin and Temp Sensor0 together as defined above as "P0" gain 115.8, time constant 171.5, dead time 2.2, max PWM 1.00, calibration voltage 24.1, mode PID M143 H0 S120 ; set temperature limit for heater 0 to 120C ;M307 H0 ;A115.8 C171.5 D2.2 V24.1 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; Informs the firmware that bed heater 0 (implied, because no P parameter is provided) uses heater 0. ; Tool 0: M308 S1 P"e1temp" Y"thermistor" A"T0" T100000 B4725 C0.0000000706 ; Configure extruder_0 temperature sensor. Attach sensor to e0_temp refer to wiki. Trianglelabs thermistor. M950 H1 C"e1heat" T1 ; Define heater 1 (hot-end E0) - bind the "e1_heat" pin (default first extruder) and Temp Sensor 1 together, as defined above as "P1" M143 H1 S280 ; set temperature limit for heater 1 to 280C ;M307 H1 A425.3 C182.6 D5.1 V24.1 B0 ; tuning parameters from 6.2.21: Heater 1 model: gain 425.3, time constant 182.6, dead time 5.1, max PWM 1.00, calibration voltage 24.1, mode PID ; Tool 1: M308 S2 P"e2temp" Y"thermistor" A"T1" T100000 B4725 C0.0000000706 ; Configure extruder_0 temperature sensor. Attach sensor to e0_temp refer to wiki. Trianglelabs thermistor. M950 H2 C"duex.e2heat" T2 ; Define heater 1 (hot-end E0) - bind the "e1_heat" pin (default first extruder) and Temp Sensor 1 together, as defined above as "P1" M143 H2 S280 ; set temperature limit for heater 1 to 280C ;M307 H2 A516.5 C163.7 D5.6 V24.2 B0 ; tuning parameters from: date 6.2.21 ; Tool 2: M308 S3 P"e3temp" Y"thermistor" A"T2" T100000 B4725 C0.0000000706 ; Configure extruder_0 temperature sensor. Attach sensor to e0_temp refer to wiki. Trianglelabs thermistor. M950 H3 C"duex.e3heat" T3 ; Define heater 1 (hot-end E0) - bind the "e1_heat" pin (default first extruder) and Temp Sensor 1 together, as defined above as "P1" M143 H3 S280 ; set temperature limit for heater 1 to 280C ;M307 H3 A480.8 C171.0 D5.7 V24.2 B0 ; tuning parameters from: date 6.2.21 ; Tool 3: M308 S4 P"e4temp" Y"thermistor" A"T3" T100000 B4725 C0.0000000706 ; Configure extruder_0 temperature sensor. Attach sensor to e0_temp refer to wiki. Trianglelabs thermistor. M950 H4 C"e0heat" T4 ; Define heater 1 (hot-end E0) - bind the "e1_heat" pin (default first extruder) and Temp Sensor 1 together, as defined above as "P1" M143 H4 S280 ; set temperature limit for heater 1 to 280C ;M307 H4 A588.5 C179.1 D7.9 V24.1 B0 ; tuning parameters from: date 6.2.21 ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Fans (all duex fans are on 24V) ; M950 F1 C"duex.fan3" ; T1 HF M950 F2 C"duex.fan7" ; T1 PCF M950 F3 C"duex.fan4" ; T2 HF M950 F4 C"duex.fan8" ; T2 PCF M950 F5 C"duex.fan5" ; T3 HF M950 F6 C"fan0" ; Cave: 24V -- T3 PCF M950 F7 C"duex.fan6" ; T4 HF M950 F8 C"fan2" ; Cave: 24V -- T4 PCF M106 P1 S255 H1 T50 : T1 HF M106 P2 S0 ; T1 PCF M106 P3 S255 H2 T50 : T2 HF M106 P4 S0 ; T2 PCF M106 P5 S255 H3 T50 : T3 HF M106 P6 S0 ; T3 PCF M106 P7 S255 H4 T50 : T4 HF M106 P8 S0 ; T4 PCF ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Set up the Tools, which combine heaters, fans, and sensors to work as one Tool. ; Tool 0 M563 P0 S"T0" D0 H1 F2 G10 P0 X-9 Y39 Z-5 ; Set Nozzle offset G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C ; Tool 1 M563 P1 S"T1" D1 H2 F4 G10 P1 X-9 Y39 Z-5 ; Set Nozzle offset G10 P1 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C ; Tool 2 M563 P2 S"T2" D2 H3 F6 G10 P2 X-9 Y39 Z-5 ; Set Nozzle offset G10 P2 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C ; Tool 3 M563 P3 S"T3" D3 H4 F8 G10 P3 X-9 Y39 Z-5 ; Set Nozzle offset G10 P3 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ; Miscellaneous ; ; Advanced calibrations: ;M593 F50 ; cancel ringing at 50hz https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/ ; Pressure advance M572 D0 S0.2 ; pressure advance T0 M572 D1 S0.2 ; pressure advance T1 M572 D2 S0.2 ; pressure advance T2 M572 D3 S0.2 ; pressure advance T3 M911 S23 R24 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ;M376 H15 ; bed compensation taper ; ; --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ; ;Tool Offsets (!ESTIMATED! offsets): ; V6-tool: X-9 Y39 Z-5 <<<<<<<<< same as V6 ; Volcano-tool: X-9 Y39 Z-13.5 ; Hemera-tool: X-37.5 Y43.5 Z-6 G10 P0 X-9 Y39 Z-5 ; T0 -5 is large distance to bed G10 P1 X-9 Y39 Z-5 ; T1 G10 P2 X-9 Y39 Z-5 ; T2 G10 P3 X-9 Y39 Z-5 ; T3 ;deselect tools T-1 ;M501 ; Store parameters. Deprecated?Please help? I am totally stumped.

Thank you.

-

I'd firstly for ease of use move your M584 to after you drive definitions.

And I can't see any axis limits for the coupler?

-

@voodoobane The normal setup on an e3d toolchanger is not to have any sort of endstop for the C axis. Instead the motor is just driven until it hits the physical stop (the homec.g file will normally reduce the motor current during this process). It looks like you have a stall detection endstop defined. Perhaps that is causing problems. DC42 published his toolchanger configuration here: https://github.com/Duet3D/RRF-machine-config-files/tree/master/E3D_Tool_Changer/dc42-duet3-centreZero-2Titan-2Hemera/sys

I have something very similar setup on my TC and it seems to work fine...

-

Stall detection does not work for the coupler stepper.

Here are the relevant bits from my code:

; from config.g file ; C (tool coupler) (M92 is set so G1 commands are in degrees) M92 C182.044 ; ( 32 steps-per-rev (stepper) * 64 (gearbox) * 2 (gears) * 16 (microsteps) ) / 360 M203 C5000 ; max speed (mm/min) (default 300) (suggested 5000) M201 C500 ; acceleration (mm/s^2) (default 20) (suggested 500) M566 C2 ; max instant speed change (jerk) (mm/min) (default 12) (suggested 2) M906 C500 ; motor current (mA) (stepper rating 400mA RMS per phase) (suggested 500) M350 C16 I1 ; 16x microstepping with interpolation M208 C-41:225 ; set axis min/max values (determined by testing); --- homeC.g --- ; --- compute max C rotation --- var cmin = move.axes[3].min var cmax = move.axes[3].max var ctot = {var.cmax} - {var.cmin} ; --- home C --- M400 ; wait for any moves to finish M913 C50 ; insure "normal" stepper current G91 ; relative moves G1 H2 C{-var.ctot} F5000 ; turn CCW to limit of rotation G92 C-41 ; set logical position (determined by testing so unlocked is 90, locked is 180) M98 P"tool_unlock.g" ; turns to 90; --- tool_lock.g --- M400 ; wait for moves to finish M913 C100 ; increase current to improve locking G90 ; absolute moves G1 C180 F5000 ; turn to locked position M400 ; wait for moves to finish M913 C50 ; restore current to normal; --- tool_unlock.g --- M400 ; wait for moves to finish M913 C100 ; increase current to improve unlocking G90 ; absolute moves G1 C90 F5000 ; turn to unlocked position M400 ; wait for moves to finish M913 C50 ; restore current to normalFrederick

-

I agree with Rushmere3d, you need to add some limits for C.

I have 0 and 500 on mine.

; Axis Limits NEED CHANGING FOR TC. CONSERVATIVE GUESS NOW for XY M208 X-14 Y0 Z0 C0 S1 ; set axis minima M208 X330 Y265 Z350 C500 S0And this is my home C file:

; homec.g ; called to home the C axis (coupler) ; ;G91 M400 G92 C499 M400 M913 C60 ; MOTOR TO 60% CURRENT G1 H1 C0 F2000 ; M400 G92 C0 ;G90 M913 C100 ; MOTOR TO 100% CURRENT G1 C0 F10000 ;Open Coupler M98 P"/macros/Coupler - Unlock"I have the lock position as C33 and unlock as C125

-

I will try this guys!

-

All I see is the homeC.

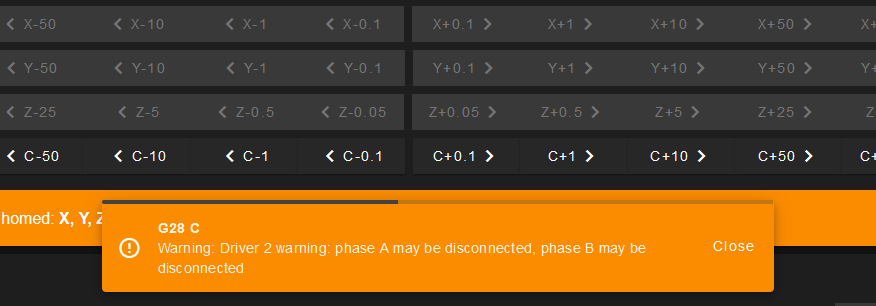

But no I have another problemIs it normal if this isn't all set to have the Home C tell me the wiring is wrong? I have a 2nd motor just in case. and it gives me the same error. I double-checked my wiring and everything. I do not understand it is saying my wiring is bad. could s0 and s1 be a factor? I have little information about this tool changer motor.

-

@voodoobane I checked the A and B poles and they are correct.

-

@voodoobane said in e3d TC coupler motor is not moving and homing C has no errors?:

Is it normal if this isn't all set to have the Home C tell me the wiring is wrong?

What message are you seeing, and what firmware version are you using?

-

@dc42 I using Version 3.4

-

@dc42 I figured it out... Driver 2 is bad...

-

How did you determine that?