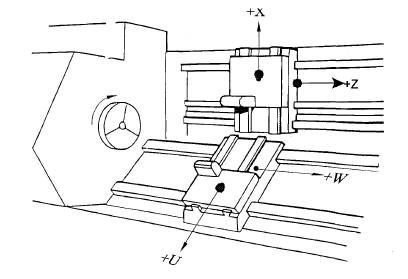

This is my very heavily modified machine, which started as a Tronxy X5SA Pro.

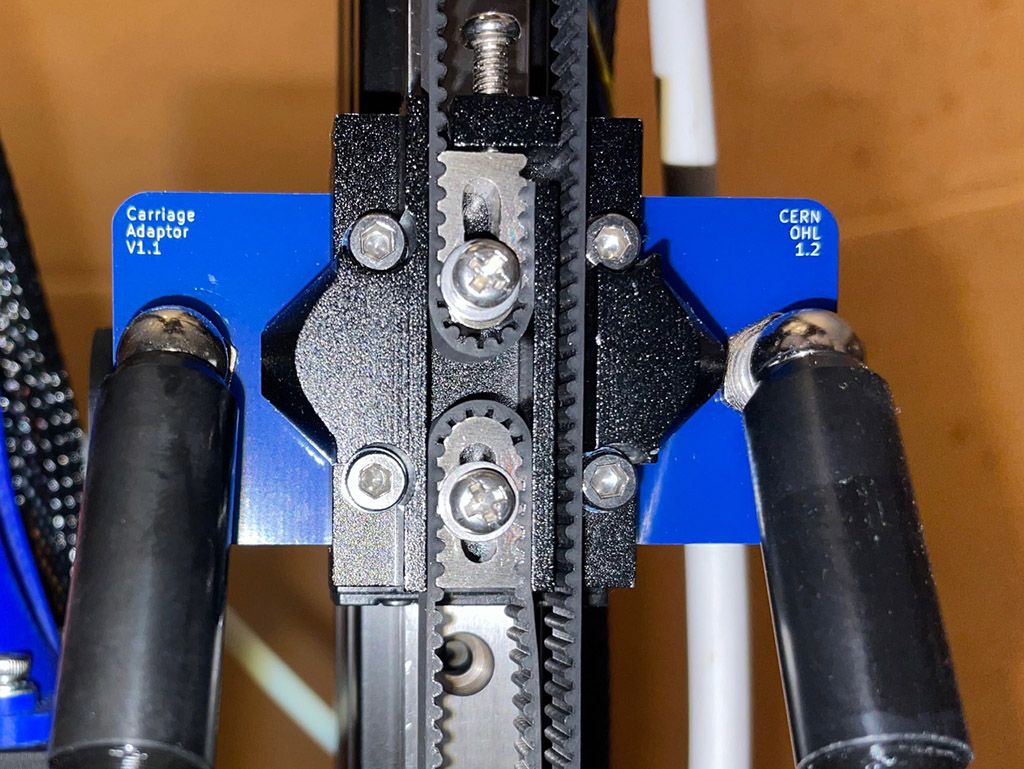

The head carriage is totally replaced with a wider version based around a machined 8mm aluminium plate that has space for an E3D toolchange system between the slideway bearing mounts.

That has a printed "cap" which has the anchor clamps for the belts built in to it, plus channels for the various cables, mount points for the X limit and a BLTouch probe, with slots to take captive nuts for the various retaining screws.

(The cable end anchors etc. and cable support strips are the E3D ones.)

The Z drives are independent and all endstop switches are now optical.

The toolholders are mounted on bases fitted to the rear (originally front) extrusion, and to make space above that the drive belt idler pulleys are relocated back by 34mm using short sections of extrusion fitted on spacers, so the original idler mount locating screw position is now in line with the cross extrusion mounting screw.

The Duet 6HC board is in an aluminium enclosure in the base, at present just resting in place. There is clearance to add a couple of thin rails across the frame to mount it on, and the PSU will probably go on a side extrusion.

There is a tool distribution board in a plastic box on the rear of the frame, and toolboard cables plug in to that - or a dummy plug can be fitted to bypass the CAN chain if one is removed.

The tools are, right to left:

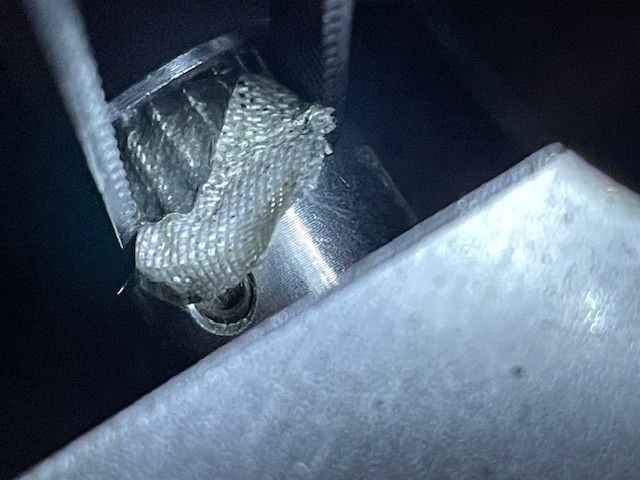

V6 bowden with hardened nozzle and hemera extruder, to allow for carbon filled materials.

V6 bowden using the original tronxy titan extruder for general use.

Hemera direct, to allow for flexible materials

Plus a part build E3D ASMBL.

I'm still spending more time doing fine adjustments than printing so far; the original bed had quite a significant sag in the middle, between its support rails, so I have added a glass bed over that which has given a great improvement, but still a slight cornerways tilt I'm trying to adjust out.

All the modifications are plug-in or bolt-on, the machine can be completely restored to its original specification. It has lost a bit more printing area than I originally expected, but still a lot bigger than my Overlord Pro.

The entire setup could be moved to or used on one of the larger TronXY machines, eg. a 500 or possibly a 600, if the head slide uses the same rail section.

If anyone wants more details of the head mods or the files for those, or any other info about it, let me know.