Coming soon to a PanelDue near you...

Best posts made by dc42

-

RE: Does anyone here work on Superslicer?posted in General Discussion

-

Software bundle 3.4.0 stable released!posted in Firmware installation

On behalf of the Duet3D team I am please to announce the release of RepRapFirmware, Duet Web Control and Duet Software Framework 3.4.0 stable.

RepRapFirmware 3.4.0 brings more than 90 new and improved features and around 80 bug fixes. New features include:

- Input shaping, to allow faster print speeds without exciting ringing

- Thumbnail image display of print files in Duet Web Control and on PanelDue (requires a compatible slicer and PanelDue firmware 3.4.1-pre2

- Heater feedforward, to maintain more even nozzle temperatures on high flow rate extruders

- More flexible control of power supplies

- More control over machine behaviour when heater faults, stepper driver warnings etc. occur

- Support for the new Duet 3 MB6XD main board for use with external drivers, and the EXP1HCL closed loop stepper motor control board

- Coordinate rotation in the XY plane

Duet Web Control and Duet Software framework now provide:

- Thumbnail image display

- Improved plugin support and new plugin guides for DWC and DSF

- A new HTTP class library for remote control of Duets in standalone and SBC mode

- 12864 display support in SBC mode

Important! If you are upgrading from software 3.3 or earlier, read at least the upgrade notes section of the RRF 3.4.0 release notes to see what alterations if any you may need to make to your configuration and macro files. Users already running 3.4.0RC2 can instead check the abbreviated release notes.

Upgrade instructions:

- For Duet in standalone mode you can find the upgrade files here. Most users can just upload the Duet2and3Firmware-3.4.0.zip file.

- For Duet with attached Single Board Computer, upgrade from the stable feed on the Duet3D package server using apt-get as usual.

Please do not use this thread to report issues with this release that require a response; start a new thread for those instead.

-

New stable firmware bundle 3.2 releasedposted in Firmware installation

On behalf of the Duet 3D team I am pleased to announce RepRapFirmware 3.2 stable. Here are the upgrade instructions:

- If you are running RepRapFirmware 3.0 or later in standalone mode, download Duet2and3Firmware.zip from https://github.com/Duet3D/RepRapFirmware/releases/tag/3.2 and upload it to your Duet via the web interface

- If you are using Duet + SBC, update from the package server in the usual way (

sudo apt-get updatefollowed bysudo apt-get upgrade) - If you are running RepRapFirmware 2.x you will need to upgrade to firmware 3.0 first, then you can immediately upgrade to 3.2. Alternatively, if you are comfortable using Bossa, you can upgrade directly to 3.2 using Bossa.

Upgrade notes and change lists:

- RRF: https://github.com/Duet3D/RepRapFirmware/blob/v3-dev/WHATS_NEW_RRF3.md

- DWC: https://github.com/Duet3D/DuetWebControl/blob/master/WHATS_NEW.md

- DSF: https://github.com/Duet3D/DuetSoftwareFramework/blob/master/WHATS_NEW.md

If you encounter problems with this release, or problems upgrading to it, please start a new thread to describe those issues.

Edit: If you are on the unstable package feed (Duet + SBC), you can update to the latest version as usual again. The corresponding packages have been fixed.

-

RepRapFirmware road map Q1 2021posted in Future Direction

These are our current plans for RRF over the next few months:

RRF 3.2: release candidate 2 appears to be very stable so we plan to release 3.2 final very soon.

RRF 3.3: this is planned to be a short cycle. Work on it has already started. The focus is on making Duet main boards easier to test using our new CAN-based automatic test equipment. As a side-effect of this work, there may be experimental support for using a Duet 3 Mini as a Duet 3 expansion board (see the M954 command), however functionality will probably be limited to driving motors and reading/writing GPIO ports. RRF 3.3 will also increase the maximum number of axes supported to 15, and I expect to provide support for tuning heaters on regular Duet 3 expansion and tool boards. Some other easy-to-implement features may be included. I hope to have a release candidate available by the end of January.

RRF 3.4: the focus of this will be the motion system. We will be looking at input shaping, S-curve acceleration, better cornering algorithms, and other mechanisms to improve print quality. Alongside this we will remove the limitation on using endstops connected to Duet 3 main boards to control motors connected to expansion boards. We expect to start work on this in February. We have a long list of other new features for consideration in this release, including further improvements to the performance of the Duet 3 MB6HC board.

-

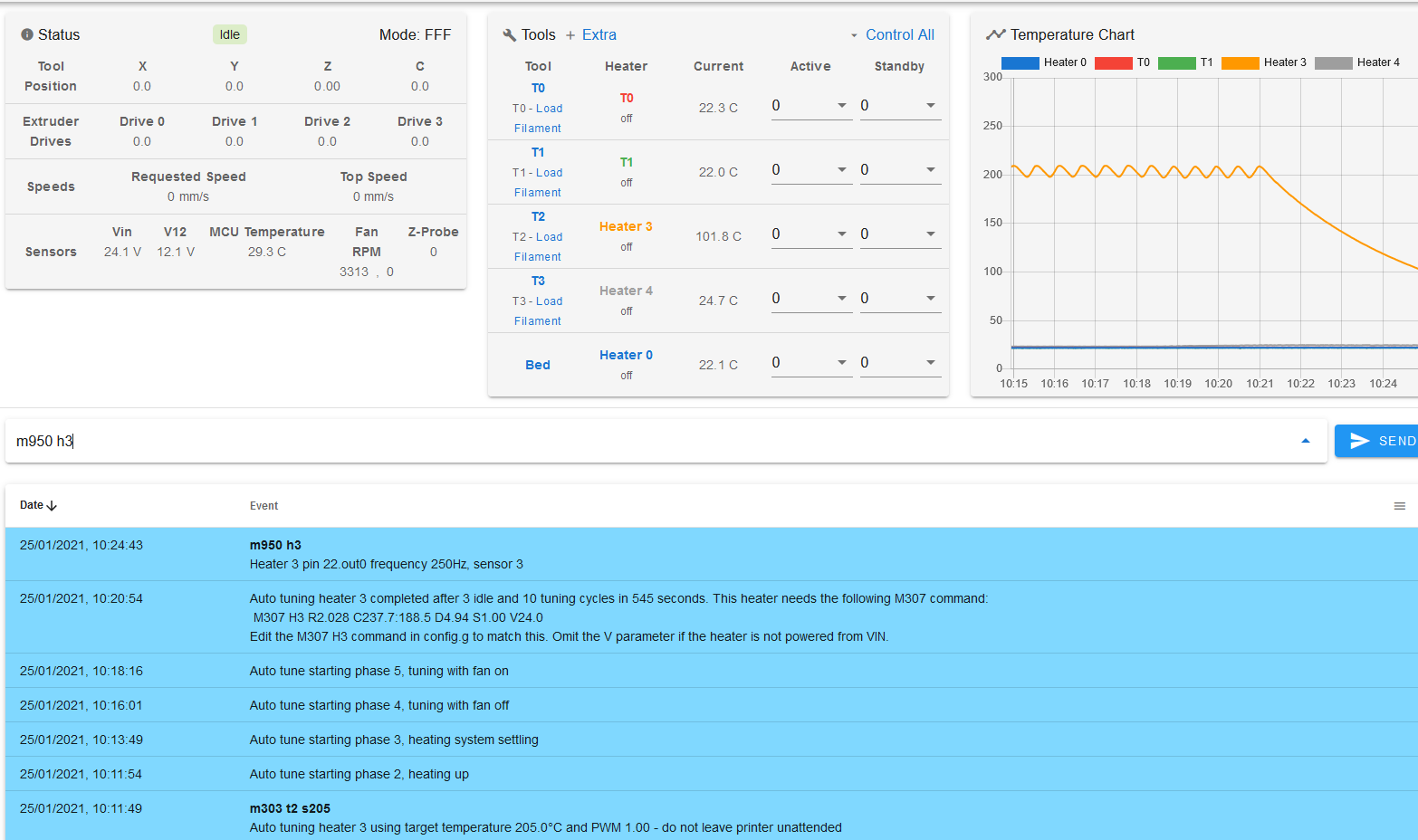

New heater tuning algorithmposted in Beta Firmware

I finally found time to implement the new heater tuning algorithm. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware.

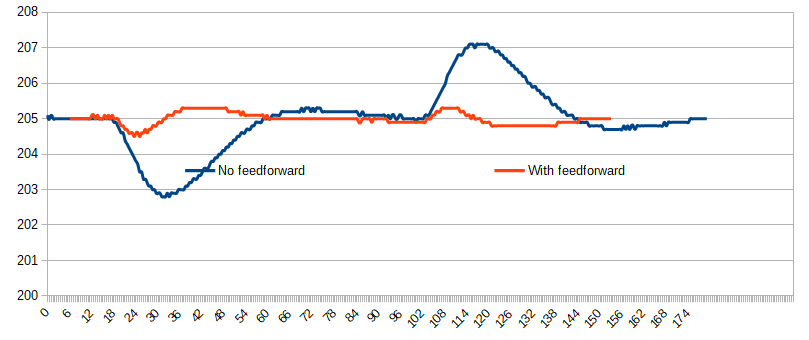

The new algorithm also tunes the heater with related fans both off and on. The purpose of this is to allow the heater control to implement feedforward, which monitors fan PWM changes and adjusts the heater power in advance of the PID algorithm spotting that something has changed. Here is a temperature plot showing the effect on reported hot end temperature when a print cooling fan is turned on and then off, with and without feedforward.

The new algorithm is implemented in RRF 3.2beta3.2 which I hope to release later today. Subject to the feedback I receive from beta testers, I hope to include it in tool and expansion board firmware too in the RRF 3.2 final release.

-

RepRapFirmware 3.0 is released!posted in Firmware installation

I am pleased to announce the release of RepRapFirmware 3.0, the first stable release in the RepRapFirmware 3 series.

Users of Duet 3 with attached Raspberry Pi can upgrade to it using apt-get update and apt-get upgrade as usual, from either the stable or the unstable package feed.

Duet 2 users and Duet 3 users running in standalone mode can download it from https://github.com/dc42/RepRapFirmware/releases/tag/3.0. Most users should be able to upgrade just by uploading the .zip file to /sys in Duet Web Control.

If you are currently using RepRapFirmware 2.x, you will need to make significant changes to your config.g file when upgrading to RRF3. See https://duet3d.dozuki.com/Wiki/RepRapFirmware_3_overview#Section_Summary_of_what_you_need_to_do_to_convert_your_configuration_and_other_files for details. You should read this thoroughly and plan your migration to RRF3.

Now that RepRapFirmware 3 is released, I do not plan to do any further releases of RepRapFirmware 2.x or 1.x. But of course it is possible for others to fork the repository and do their own amendments to 1.x and 2.x.

-

Software package 3.3beta3 releasedposted in Beta Firmware

On behalf of the Duet3D team, I am pleased to announce the release of software package 3.3beta3. This release brings the following:

- Global variables are now included in the object model. This means they can be viewed in the DWC Object Model browser and can be accessed by SBC add-ons.

- The DWC Object Model browser now provides a summary of what each value means

- RRF and DWC now support accelerometers (currently in standalone mode only) in preparation for the forthcoming support for input shaping. See https://duet3d.dozuki.com/Wiki/Accelerometers.

- Many other minor improvements and bug fixes

RRF release notes: https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-3.x-Beta-&-RC#reprapfirmware-33beta3

DWC release notes: https://github.com/Duet3D/DuetWebControl/releases/tag/v3.3-b3

DSF release notes: https://github.com/Duet3D/DuetSoftwareFramework/releases/tag/v3.3-b3Users of Duet + SBC can upgrade from the unstable package server.

Users of Duet in standalone mode can upgrade using the files at https://github.com/Duet3D/RepRapFirmware/releases/tag/3.3beta3. The IAP files have not changed but they are included in this release because some users may need to re-upload them to put them in the correct folder on the SD card.

-

RE: Duet hardware actually makes it into Thomas Salanderer's videosposted in General Discussion

A genuine Einsy Rambo board is $120 on Ultimachine's web site, and it has only 4 stepper drivers, an 8-bit processor and no web interface. So I think $130 is in the right ball park for a high-quality board that comes with support and a warranty. In time I expect the price will come down.

MKS can only sell boards as cheaply as they do by parasitising open source designs, violating the open source license agreements, offering no support and little or no warranty, and selling boards before they have got the design right (as happened with the SBase). We're not like that.

-

RE: Email/notifications from Duet wifiposted in Duet Web Control

Our latest thoughts about this are to embed a MQTT client in RRF that publishes messages about the current state of the printer e.g. printer powered up, print started, print completed, print paused by filament monitor.

Latest posts made by dc42

-

RE: Closed loop noise/oscillationposted in Tuning and tweaking

@Tech_Sam03 have you tried slightly lower P and slightly higher D?

-

RE: 3.6.0 B4 threw an errorposted in Beta Firmware

@Adrian52 thanks for your report. Code 7 step timing errors were the last critical error we needed to fix before 3.6.0-rc.1. Thanks to the feedback from @Aurimas I was able to identify the area of code and the bug that is the probable cause of these errors. The data you posted helps confirm that as the cause. We now hope to release rc.1 early next week.

-

RE: 3.6.0 beta.4 stepper timingposted in Beta Firmware

@GeoffVR6 unfortunately you didn't provide the step timing error message, in particular the error code number in it; so there's nothing I can do. However, we believe that the code 3 errors were fixed in 3.6 beta 3, the code 2 errors were fixed in beta 4, and the code 7 errors are fixed in the forthcoming RC1. We haven't seen any other step timing error codes reported.

-

RE: Duet not communicating after installation of firmwareposted in Firmware installation

@konvalm FYI we have an outstanding ussie regarding this situation:

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

@Superbrain8 thanks, we created this issue:

https://github.com/Duet3D/RepRapFirmware/issues/1094

It's scheduled to be fixed between 3.6.0-rc.1 and 3.6.0 stable.

-

RE: Having problems with M118 and variablesposted in Gcode meta commands

@fcwilt are you running in standalone or SBC mode?

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

@dwuk said in Sovol SV08 Multiple Motion System Upgrade.:

Also when you just use the button's to move the U & V - they don't react instantly - so I am wondering where there is some sort of comms issue in 3.6.0b4 - as I don't notice this in 3.5.4

There are known synchronisation issues in 3.6beta releases including beta 4 when a main board is used in expansion mode. These have now been resolved.

-

RE: 4-tower deltaposted in MultiAxis Printing

@droftarts @luca-Massimiliano RRF does support additional delta "towers" but not to add extra degrees of freedom to the effector, only for e.g. keeping an extruder drive at the correct height so that a shorter Bowden tube can be used between it and the hot end.

-

RE: Connecting a thermistor directly to the expansion port (Duet2)posted in Duet Hardware and wiring

@rbjam83 you can use a 1% resistor, it may just reduce the accuracy a little.

-

RE: Question about scanning Z probeposted in Duet Hardware and wiring

@fcwilt said in Question about scanning Z probe:

I'm getting this warning:

Warning: obsolete object model field sensors.probes^.diveHeight queried

Why does this happen?

Because you have a macro that refers to

sensors.probes[N].diveHeightfor some N. Usesensors.probes[N].diveHeights[0]instead, or diveHeights[1] if you want the dive height for the second and subsequent probes at the same point.@fcwilt said in Question about scanning Z probe:

Since the probe is analog, and there is no "on/off" trigger height, what exactly does the G31 Z param do?

If you use the probe with a G30 command and you don't switch it to the experimental touch mode, then it behaves like a regular probe and G31 Z sets the trigger height as usual.