Need advice on new heated bed aluminium plate

-

I am in the process of converting my Cartesian from 12V to 24V.

As a part of this of course I need to exchange the heater and I already ordered an appropriate silicone heater from Keenovo. But my question is about what to attach the heater to. An aluminium plate is of course the answer but I have different options here and not sure what makes the most sense for a Cartesian printer with bed moving in Y direction.

- Use an aluminium sheet with 3mm thickness. This matches my current integrated aluminium plate and PCB heater solution in thickness and in weight. Since I print on glass (mirror) either way (at least so far) it would not have to be a 100% flat (and in 3mm I won't get high quality precisely ground plates anyway - or at least I did not find any)

- Use a precision ground 5mm aluminium plate. This gives me more options on what to add as the build surface since this plate would already provide the flatness required. But it adds substantial weight to this axis (it weighs around 650g compared to around 400g for the 3mm version). Another advantage would be that this plate is definitely thick enough to add a thermistor into the top side without risking to drill through it (with only a cordless drill and some hand tool in the first place

)

)

In terms of price they are close enough to each other that this is not a factor. My motors are beefy enough to not really care about the additional about 250g to be slammed around but I am more concerned about ringing while not having to reduce the acceleration too much.

Any advice or experiences on this topic would be highly welcome.

P.S.: Details about my printer can be found behind the link in my signature.

P.P.S.: I could counteract the additional weight by replacing the glass with something more lightweight like GeckoTek or similar. Any opinions on that?

-

I would rather use a "straight & heavier" 5.mm aluminum plate then that 3mm crap (even with glass on top).

Your current solution has uneven heat distribution (may not important for PLA, but needed when printing higher temp materials like ABS).

M Rehorst (DigitalDentist) has a nice blog post on this subject... -

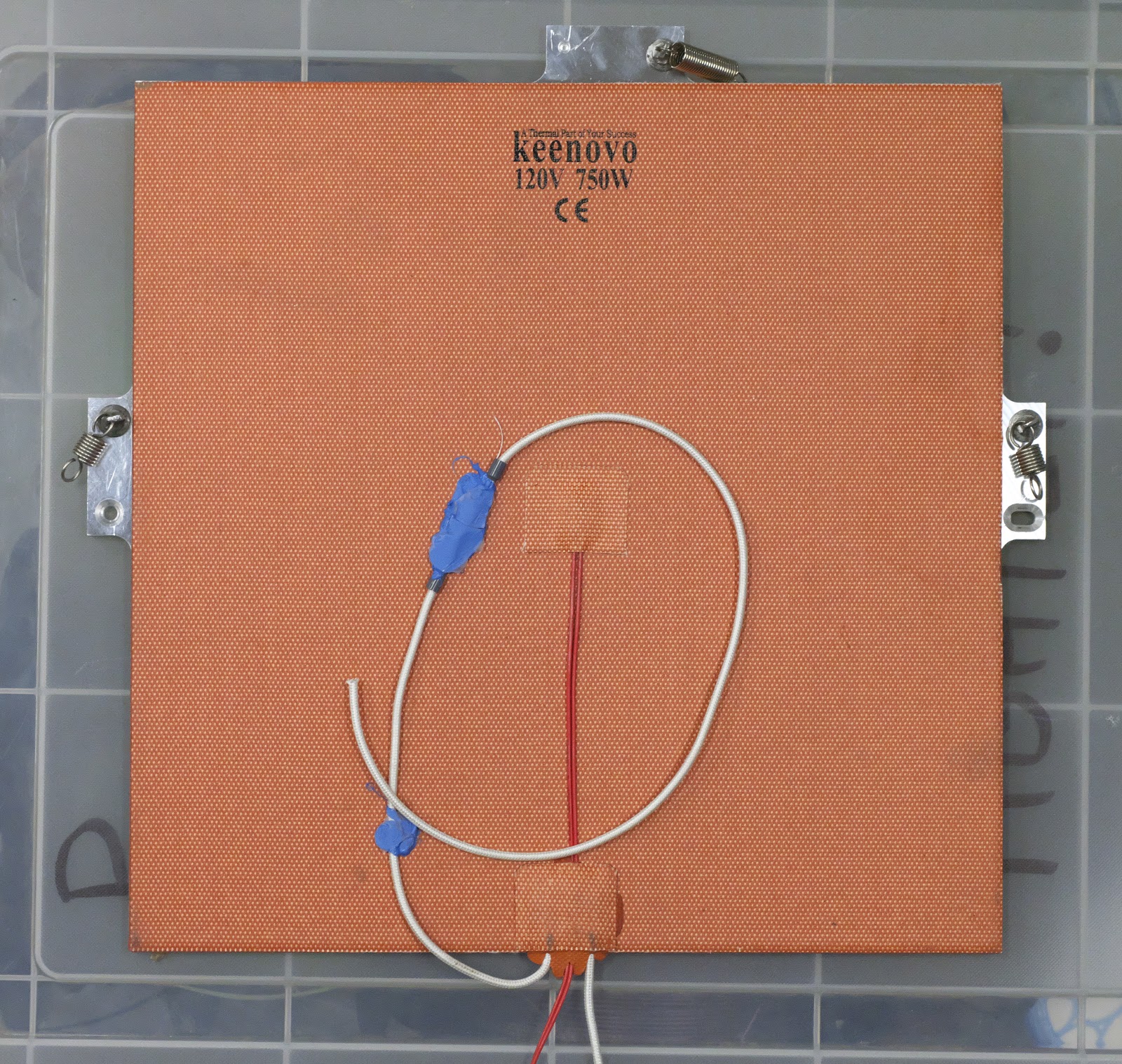

I like cast aluminum tooling plate for its flatness, uniform thermal expansion, and ease of machining. I recently replaced the bed in my i3-style machine, SoM, with a new plate on a kinematic mount, Keenovo 750W line powered heater, and PEI print surface. I had some concerns about whether the springs holding the plate down on the leveling screws would be sufficient to keep the keep the bed in position when printing, but it seems to be working fine and I can print over 100mm/sec with it (I haven't pushed it to the limit yet).

I'm currently using a very large NEMA-23 motor to drive that axis, but it's overkill and I may swap in a smaller motor.

One warning about the Keenovo heaters- the one I installed on UMMD's bed about 2 years ago is letting go of the bed plate now. It used the standard 468MP adhesive. I'd start inspecting it frequently after about a year of use, and plan on reattaching it when it starts letting go. I'll be using some high temperature silicone to reattach the heater on UMMD in the next week or so.

In UMMD I used a TCO bolted to the bed plate as a safety device in the event of bed heater SSR failure. That won't work if the heater comes off the bed, so in SoM (see photo above) I mounted the TCO on the heater (it's inside the blob of blue high temperature silicone). If the heater comes off the bed the TCO will stay with it and do its job. I'll be doing the same with the TCO when I reattach the heater in UMMD.

-

Okay, so looking at your printer, it appears that the bed moves in the Y axis.

Since you have a Bowden extruder, the X axis is going to be much lighter than the heavier bed, so increasing the moving mass in the Y axis is going to slow down your printing, in that you will need to use lower values for accel in the Y axis with the heavier mass, all else equal.

However, if you are upgrading from 12V to 24V, you might find that your motors will deal with it better overall, though there will still be some ringing, just as a part of the nature of the drive belts. Well, any drive system, really.

I added a couple of pieces of aluminum bar to my Y axis as a part of getting my Piezo Andromeda sensors set up. Maybe a couple hundred grams, I didn't weigh them specifically. It didn't seem to make a noticeable difference in the ringing that I get in the Y axis, but I also print somewhat slowly, since the leadscrew drive configuration that I use doesn't lend itself to very high speed moves. I hardly ever have anything above about 75mm/s, and perimeters are never over about 50mm/s.

How much does your mirror weigh? If you can print without it on the aluminum, that's probably a better solution anyway. Glass is terrible for thermal properties. I use it myself because I like the super-smooth first layer, but I'm looking at solutions to print without it, since almost everything that I print can tolerate a slightly rougher surface texture, and even the 2mm glass that I'm using has its weight to consider.

In your position, I would probably use the 5mm plate, and do away with the glass. Use a PEI sheet or similar instead, and you'll have more even heating, and probably better adhesion with most prints. It's likely that you'll be much happier with the overall result, even if you have to slow down your Y accel by a few percentage points.

-

First of all thanks for all your answers - or basically that one same answer from all of you.

@whosrdaddy I don't print ABS - I never have and I never will nor any of its related cousins like HIPS or ASA. Due to space restrictions the printer has to be in a living area and it has no enclosure so anything that spits out that much "dirt" will never be printed. I print PETG though that right now because of the insulation the glass sadly provides has to be printed with a rather hot bed also (starting at 90°C going down later).

@mrehorstdmd Thanks for the warning. My heater has a builtin thermostat set to 150°C and also is "just" 200W (I don't mind the heating speed but want to limit the max temp by laws of physics - also on a 200x200mm heater this gives nice 0.5W/mm²). I don't know yet how this is attached/wired since the heater is still in transit but it will more or less match your approach of silicone-gluing the TCO directly to the heater.

I also thought of directly sticking the heater to the aluminium plate with HT silicone but for now I will start with the included 468MP.One question: how large is the bed of SoM?

@SupraGuy Small correction: it is a direct drive extruder not a Bowden. The PTFE tube going to the extruder is just reverse Bowden (or filament feeder tube) so that a movement of the extruder does not result in pulling the filament spool. Still compared to the bed it is rather light.

I am also already looking forward to how the motors perform with 24V. As I said they are quite beefy already and sling the bed with 1+kg back and forth like it was paper. And this with up to 250mm/s and 2000mm/s² accel. So I don't assume my motors not coping with the extra 250g just the increased chance of ringing. But then there is always Dynamic Acceleration Adjustment that I will tune sooner or later anyway.

The mirror weighs between 300 and 350g. And as written a bit above I know about the more or less thermal insulation properties of glass but it is most probably more flat than the aluminium plate included with the original Anet A8. Also since quite some time I put also glue stick on the glass so replacing it with anything else also won't have that much influence on the bottom layer appearance.

Thanks again for all the answers. I will go forward with 5mm cast aluminium tooling plate.

-

Actually the 5mm ALU plate is at least 100g lighter than 3mm glass + 3mm ALU

-

@obeliks That is right but if I put the glass again on top of the 5mm aluminium it will be heavier.

This might be a stupid question but can I print directly onto aluminium? I never tried or researched about it being possible. But I guess it won't stick because otherwise one would see that more often?!

-

@wilriker said in Need advice on new heated bed aluminium plate:

This might be a stupid question but can I print directly onto aluminium? ..............

Yes and no doubt the digital dentist (@mrehorstdmd ) will advise you to do just that. Personally, I don't like the idea but I'm not going to elaborate as it inevitably leads to an argument.

-

@deckingman Thanks for at least telling me that it is possible. So far I always thought it would not work at all but also never tried.

Another idea that I have is to get some high temperature magnets and inset them into the aluminium plate so I can use spring steel sheets directly on top of it (just like Prusa i3 MK3). But my problem is that I don't have the slightest idea where to find a milling machine or CNC router. No makerspaces near to me and the closest one (about 100km away) does not have either of these machines. So I will have to resort to magnetic sheets that get 468MP'd to the aluminium - again adding weight.

I don't know why I am so concerned about the weight. It just bugs me although I should know better looking at the printer you built.

-

@wilriker said in Need advice on new heated bed aluminium plate:

I don't know why I am so concerned about the weight. It just bugs me although I should know better looking at the printer you built.

Ah well Manuel, I built mine from scratch whereas you have started from a kit. So you have the limitations of the original design and hardware. Therefore, you should be concerned about the weight because your frame and motors will limit the mass that you can reasonably move. Or more precisely, they will limit that speed at which you can move that mass before you run into problems.

You are gaining a lot of good experience though - this wil stand you in good stead when you come to design and build a "proper" printer

.

. -

@deckingman I started from a kit but as soon as the 24V conversion is finished virtually nothing will be left of the original printer.

Anyway, you are right about the experience part. That is something I noticed along my journey several times. And since I rarely need a 3D printer this will stay a learning-tinkering-project.

But ultimately I want to convert to something where the bed moves in Z and no longer in Y. Not sure if that will be a cubed Cartesian or a CoreXY or Markforged or HaqXY or whatever there also is. But I am pretty sure it won't be a Delta. Let's see where this journey goes.

-

@wilriker SoM and UMMD's beds are 300x300mm. SoM uses 1/4" thick MIC6 and UMMD uses 8mm thick MIC6. Both have the same Keenovo 750W heater. SoM gets to 100C to print ABS in about 2 minutes (faster than the extruder gets to 240C!) and UMMD takes about 4.5 minutes to get to 100C.

I have never heard of anyone successfully printing directly on aluminum (not sure where @deckingman would get the idea that I would advocate that). I print on PEI. Most common materials love to stick to PEI. ABS prints with sharp corners sometimes lift a bit and I have found that a little glue stick stops that completely.

I glue the PEI to the bed plate with the same 468MP adhesive that is used on the heaters. One nice thing about gluing the print surface down is that there's nothing sticking up over the bed surface to crash the extruder nozzle into. It lets go after a couple years as it does on the heater.

I haven't checked to see whether the adhesive on UMMD's bed is letting go of the aluminum or the heater. When the PEI was lifting on SoM the adhesive stayed on the aluminum. Either way, I'll clean off the old adhesive before applying the high temperature silicone. Paint stripper and a scraper works.

-

@wilriker said in Need advice on new heated bed aluminium plate:

I also thought of directly sticking the heater to the aluminium plate with HT silicone but for now I will start with the included 468MP.

Go straight for the high temp silicone. The 468MP sticker isn't adequate in the long run, and when you decide to remove it, it will be painful to get unstuck from the heater pad and using a razor to scrape it off the aluminum is one thing, but risks damaging the silicone. A 6$ tube of RTV silicone is the way to go.

For the print surface, go with a PEI sheet stuck with 468MP. PEI + PVA glue stick will stick and release anything.

-

@phaedrux Thanks. Will probably go this way then. I thought the 468MP would already be attached to the header upon delivery but thinking about it they would not know how I want to attach it so they probably just put it separate into the package.

Another question that came to me today: is there any reason but to use very thin (0.5-1mm) float glass on top of the aluminium? My mirror is 3mm thick and insulates quite a bit but delivering nice looking first layer at the same time. I could reduce the insulation factor of glass by just using thinner one, couldn't I?

-

@wilriker said in Need advice on new heated bed aluminium plate:

Another question that came to me today: is there any reason but to use very thin (0.5-1mm) float glass on top of the aluminium? My mirror is 3mm thick and insulates quite a bit but delivering nice looking first layer at the same time. I could reduce the insulation factor of glass by just using thinner one, couldn't I?

IMO if you already have a flat aluminium bed, the main advantage of using a glass bed on top of it is so that you can remove it, either to put it in the fridge or freezer to help the print release from the bed, or so that you can put another glass bed on immediately and start a new print, or so that you can use different print surfaces on different glass plates (PEI, glue etc.) for different types of filament. A thin glass plate wouldn't be safe to handle like that.

-

The heater will come with the adhesive already attached so you can just peel and stick the heater to the plate. It works fine for about 2 years of printing ABS at 100C, maybe longer if used at lower temperatures.

Very thin glass breaks more easily than thicker glass. Glass chips and ball bearings/human flesh are not good combos.

Over time a PEI surface will get scratched up (especially if your printer is at a makerspace!). One of the facts of FDM printing life is that no matter what the print surface is, the bottom of a print will always look different from the top and sides.

-

2mm glass is the absolute minimum. I used it for a while and I had no problems. Except when a spool fell on it.

-

I know some of you are aware of these plates...

Has anyone here used one of these plates before?

Im thinking about thinking of building a new printer and I think Im going to go corexy. I'd really like to use a bed like that so as not to deal with all the.. pardon my italian... bed adhesivion fuckery

-

Hi,

I am dealing with the same issue.

So where can one get a precision ground aluminum plate made to size?

Frederick

-

If your in the US, try these guys...

https://www.midweststeelsupply.com/store/castaluminumplateatp5