Eh, I needed to fetch a beer from the storage. So I hopped in to the "workshop"

Anet steppers are 37,8mm long and Wantai real length is 46,8mm.

And the beer is imperial IPA with 10% alcohol. And it is brilliant.

Best posts made by OBELIKS

-

RE: My custom Cartesianposted in My Duet controlled machine

-

RE: Pressure Advance Calibrationposted in Tuning and tweaking

@digitalvision Thanks.

Now can someone explain my stupid ass how to output the result to a file?

-

RE: PETG Dryingposted in General Discussion

When talking about humidity you need to be careful, relative humidity (expressed in %) tells you how saturated air is.

So at 25°C air can have 20g of water per kg of air and that is 100% humidity. If you raise temperature to 65°C, air can take up to 204g, so that means relative humidity when you have 20g/kg is 32%

So at "normal" conditions ant 25°C/50%rh you have 10g/kg and when you heat it up to 65°C you still have 10g/kg, so relative humidity is 6%

But I think that temperature also plays in drying, it always helps if you get molecules moving faster.I once found these somewhere, and from what I tested they work. You basically set temperature as high as possible before glass transition.

PLA - 4h@45°C

ABS - 2h@60°C

PETG - 2h@65°C

NYLON - 12h@70°C

PVA - 4h@45°C

TPU/TPE - 4h@50°C

ASA - 4h@60°C

PP - 6h@55°C

Dessicant - 6h@65°CEdit: Missing temperature

-

RE: My custom Cartesianposted in My Duet controlled machine

Good news, I have the same result. And I think I know what is the problem. Try disabling Print Infill Before Walls. When it was printing walls I could hear it dragging against the infill and I can feel it. With Slic3r that prints walls before the infill by default I never had this issue.

-

Problem printing circlesposted in Tuning and tweaking

I have a problem I have not noticed before. It was always present, but I did not print circles except for the M3 holes. So I did not notice.

Anyway, if it not seen from the video, on the big circle printer keeps speeding and slowing. It is choppy.

And the weird thing is, there is a pattern in the circles. I get 3, 4, 5, 2, 5, 4 lines.

My config is here (fresh), I also attached the gcode file

Here is a octagon, so I could test straight lines, as you can see it works perfectly. Ignore the ugly print.

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 2.01beta2(RTOS) running on Duet WiFi 1.02 or later Board ID: 08DGM-956GU-DJMSN-6J9F4-3SD6M-1VR3G Used output buffers: 3 of 20 (16 max) === RTOS === Static ram: 28484 Dynamic ram: 96032 of which 0 recycled Exception stack ram used: 420 Never used ram: 6136 Tasks: NETWORK(ready,328) HEAT(blocked,1248) MAIN(running,3616) Owned mutexes: === Platform === Last reset 00:41:35 ago, cause: software Last software reset at 2018-07-16 21:09, reason: User, spinning module GCodes, available RAM 6208 bytes (slot 1) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 0 Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 0.0ms, max retries 0 MCU temperature: min 42.9, current 43.2, max 44.2 Supply voltage: min 12.4, current 12.6, max 12.8, under voltage events: 0, over voltage events: 0 Driver 0: standstill, SG min/max 0/383 Driver 1: standstill, SG min/max 0/458 Driver 2: standstill, SG min/max 0/652 Driver 3: standstill, SG min/max 0/524 Driver 4: standstill, SG min/max not available Date/time: 2018-07-16 21:51:26 Slowest loop: 101.17ms; fastest: 0.08ms === Move === Hiccups: 0, StepErrors: 0, LaErrors: 0, FreeDm: 240, MinFreeDm: 150, MaxWait: 0ms, Underruns: 695, 1 Scheduled moves: 0, completed moves: 0 Bed compensation in use: none Bed probe heights: 0.000 0.000 0.000 0.000 0.000 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 0 Stack records: 2 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is idle in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 172.91ms; fastest: 0.08ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.21 WiFi MAC address 5c:cf:7f:76:5f:98 WiFi Vcc 3.33, reset reason Turned on by main processor WiFi flash size 4194304, free heap 15296 WiFi IP address 192.168.1.119 WiFi signal strength -38dBm, reconnections 0, sleep mode modem Socket states: 0 0 0 0 0 0 0 0 === Expansion ===Test gcode: https://www.dropbox.com/s/hfvgd5zj1sb30em/Cylinder test.gcode?dl=0

Stl: https://www.dropbox.com/s/hkadyoitr26z2r4/Cylinder test.stl?dl=0 -

RE: Duet wifi S3Dposted in General Discussion

I think you are overthinking it. Do you have multiple beds?

If not, default setting in S3D is OK, it will output M140 S70 to set bed temperature to 70°C, and that works with Duet -

RE: My custom Cartesianposted in My Duet controlled machine

If you need more help from me just say. I can print more tests. Just prepare them for PETG.

-

RE: Pressure Advance Calibrationposted in Tuning and tweaking

@Munce31 If you are using the script @jens55 posted, you can add

print("M117 %.3f" % pressure_advance)after

print("M572 D0 S%.3f" % pressure_advance) -

RE: Slic3r PE and M900,M907 errors.posted in General Discussion

M900 command is located under filament settings, custom gcode. It is used to set linear advance factor. Delete it or comment it out.

Latest posts made by OBELIKS

-

RE: Building a Sound Dampening Enclosureposted in My Duet controlled machine

Depends. If you will make a panel with steel on both sides, then you will have better results with the lighter insulation.

That way you really decouple the sheets, if you use a stiffer one it could happen that you transfer the sound from inside to outside.

You can also benefit if you put thinner sheet metal on inside (or outside). The difference in the natural frequency helps dampening. -

RE: V-Core Pro lives again (-:posted in My Duet controlled machine

Maybe, with a different cable. It would need to be shielded

-

RE: V-Core Pro lives again (-:posted in My Duet controlled machine

I am still hunting for a durable surface that would work with IR-probe.

I have some black copy of Buildtack, but it holds too much and even a slight hit with hot hotend runis the surface.But the V-Core pro is great!

-

RE: Purge macro prusaslicer issues.posted in Tuning and tweaking

Is this the whole start code?

Because you are completely missing the temperatures.I would put this before G32

M104 S{first_layer_temperature[0]-40} ; set extruder temp M140 S[first_layer_bed_temperature] ; set bed temp M190 S[first_layer_bed_temperature] ; wait for bed temp M109 S{first_layer_temperature[0]-40} ; wait for extruder tempThis way you avoid runny extruder while printer is running mesh procedure.

Then add this before ; Purge extruder

M104 S[first_layer_temperature] ; set extruder temp M109 S[first_layer_temperature] ; wait for extruder temp -

RE: Slicing G-Code curves from solid (not mesh) geometry.posted in General Discussion

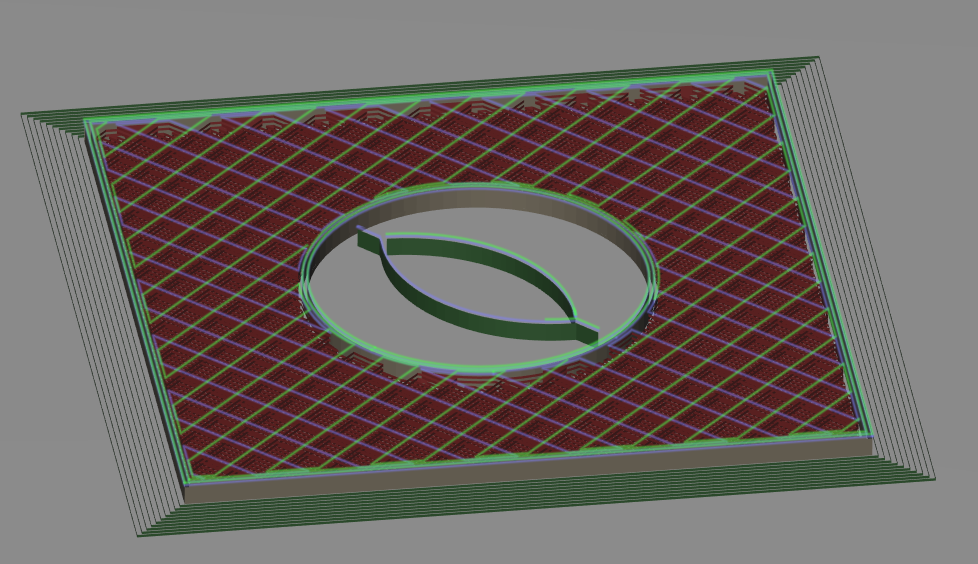

In this case it is trying to support the circle above with minimal waste. It is looking at bridges and making them shorter than a value.

-

RE: Slicing G-Code curves from solid (not mesh) geometry.posted in General Discussion

Interesting and they added 3mf export (unfortunately only in the Manufacturing space)!

And I like this support structure:

-

RE: Print quality issueposted in Tuning and tweaking

WOW

Can you make a picture with M3 bolt in the cheap idler? Is the gap visible? -

RE: New repository for machine configuration filesposted in General Discussion

Ah, that makes sense.

-

RE: New repository for machine configuration filesposted in General Discussion

Would it make sense to remove the values from M143, M906 and M208 and put them to the comment for these lines?

That way there would be no way of someone running an incompatible config. Mistakes happen, you can miss something and get in to trouble. -

RE: Print quality issueposted in Tuning and tweaking

@Dkos it's a longshot. Can you try to slice again as you did and then export to .obj and open that in Blender. It will probably not show anything out of order, but still worth a shot.