Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow

-

Hello,

Forgive me if I've missed something. I knew when I jumped into this project it would be a lot to chew, but I wanted to learn. I've put Duets in all of my machines and have always lusted after a Voron. After I saw Thomas Salanderer's live builds I decided to jump in.

This printer is super-fast and I love it, but I think I'm screwing up somewhere since it does not seem to print faster than 24.5 mm/s. (usually when I have an issue with my Duets I can figure out where I've gone wrong by reviewing others' posts, but here I am at a loss).

I wonder if my Toolboard is the culprit. Or maybe how much plastic I'm moving.

I'm printing with a Misquito Magnum 1.8mm nozzle, 2.0mm Extrusion width, 1mm layer height. I know, I'm pushing it, but that's what I'm shooting for. Previously I had printed with a 1.2mm nozzle (1.44 Extrusion width) on a Mamorubot SX4 outfitted with a Duet 2 Maestro Ethernet.

Stuff like this makes me feel like the eternal Noob, but I'm hoping someone can point out where I'm screwing up. I may have bitten off more than I can chew, but I'm determined to figure out where I'm choking. Thanks so much in advance,

ChrisHere's my config:

;; Helpful Toolboards commands

;M115 B121 ; Show board 121

;M997 B121 ; Update tool 121

;M122 B121 ; Detailed status of toolboard

G4 S1 ; wait 1s for expansion boards to start; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder movesM550 P"VoronHoward" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Printer geometry

M669 K1 ; Select CoreXY mode

M208 X10:355 Y10:370 Z-0.2:320 ; Axis Limits

M564 H0 ; allow unhomed movement;------- drives from top---------------------------------------------------

; B -------+------ A

; | P.02 | P.03 |

; -------+------- Z-Drives

; | P0.1 | P0.4 |

; -------+-------

; Front; Drive Mappings

M569 P121.0 S0 D2 ; Drive 121.0: E Axis

M569 P0.1 S1 D2 ; Drive 1: Z-LeftFront Axis

M569 P0.2 S0 D2 ; Drive 2: Z-LeftRear Axis

M569 P0.3 S1 D2 ; Drive 3: Z-RightRear Axis

M569 P0.4 S0 D2 ; Drive 4: Z-RightFront Axis

M569 P0.5 S1 D2 ; Drive 5: Expansion: A motor (Y-axis)

M569 P0.6 S1 D2 ; Drive 6: Expansion: B motor (X-axis); Motor remapping for dual Z and axis Limits

M584 X6 Y5 Z1:2:3:4 E121.0 ; Motor mapping

M671 X-60:-60:400:400 Y-6:410:410:-6 S20 ; Z leadscrews positions Left Front - Let Rear - Right Rear - Right Front; Microstepping and Speed

M350 X32 Y32 E16 Z32 I1 ; MODIFIED, XY&E were 32. Configure microstepping with interpolation

M92 X160.00 Y160.00 Z800.00 E417.00 ; Set steps per mm 1.8 motors; Speeds, Acceleration and Jerk

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X60000.00 Y60000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X6000.00 Y6000.00 Z4000.00 E250.00 ; set accelerations (mm/s^2); Motor currents

M906 X1400.00 Y1400.00 Z1200.00 E700.00 I55 ; Set motor currents (mA) and motor idle factor in percent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X345 Y345 Z300 S0 ; set axis maxima; Endstops for each Axis

M574 Z1 S1 P"io4.in" ; Z endstop switch

M574 X2 S1 P"^io5.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin ^io5.in

M574 Y2 S1 P"^io6.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ^io6.in; Z-Probe

M558 P8 C"121.io0.in" H8 F3000 T6000 R0.2 ;wired to ToolBoard; set Z probe

G31 P500 X0 Y25 Z1.4 ; set Z probe trigger value, offset and trigger height

M557 X10:340 Y10:340 S40 ; define mesh grid; Bed Heaters and Thermistor

M308 S0 P"temp0" A"Bed" Y"thermistor" T100000 B3950 ;B4725 C7.060000e-8 ; Heatbed Thermistor Sensor 1

M950 H0 C"out0" T0 Q10

M307 H0 R0.803 K0.436:0.000 D3.64 E1.35 S1.00 B0

M140 H0 ; Bed uses Heater 0

M143 H0 S116 ; Set temperature limit for heater 0 to 115C Bed; HotEnd Heater and Thermistor

M308 S1 P"121.temp0" A"HotEnd" Y"thermistor" T100000 B3950 ;T100000 B4725 C7.06e-8 ; define E0 temperature sensor

M950 H1 C"121.out0" T1 Q100 ; Create HotEnd Heater

;M307 H1 R4.568 K0.683:0.000 D4.04 E1.35 S1.00 B0 V24.4 ; PID as heater

M307 H1 R3.018 K0.407:0.013 D8.83 E1.35 S1.00 B0 ;Auto tuning heater 1 completed after 3 idle and 10 tuning cycles in 676 seconds.

M143 H1 S285 ; Set temperature limit for heater 1 to 285C HotEnd

;M302 S15 R15 ; min extrusion (cold extrusion) temp

M572 D0 S0.06 ; set extruder 0 pressure advance to 0.06 seconds;Case Fan

M950 F3 C"out5" Q500 ; create fan 3 on pin out3 and set its frequency

M106 P3 S255 H-1 ; set fan 3 value. Thermostatic control is turned off

M950 F4 C"out6" Q500 ; create fan 3 on pin out3 and set its frequency

M106 P4 S255 H-1 ; set fan 3 value. Thermostatic control is turned off; Fan Hotend

M950 F1 C"121.out1" Q100 ; Creates HOTEND Fan

M106 P1 S255 T45 H1 ;Thermostatic fan for sensors 1. 70% above 45°. Sensor 1.; Fan Part Cooling

M950 F0 C"121.out2" Q80 ; Creates PARTS COOLING FAN

M106 P0 S0 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN; Tools

M563 P0 S"MisquitoMagnum" D0 H1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Filament Sensor

M591 D0 P2 C"121.io1.in" S1 ; simple sensor (high signal when filament present) connected to 121.io1 for drive D121.0, enabledM955 P121.0 I05 ; specify orientation of accelerometer on Toolboard 1LC with CAN address 121

M593 P"zvdd" F46 ; use input shaper with zvdd profile

M911 S21.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ;auto save on loss of power -

Also, any Noob mistakes noticed would be much appreciated. Thanks. Love this forum and the top notch folks helping us all.

-

@christockos my guess is it's something to do with your slicer rather than your config. Have a look at the start gcode to see if any speeds are being set

-

I would also look at the filament cooling settings for min layer time, that will slow down the print.

-

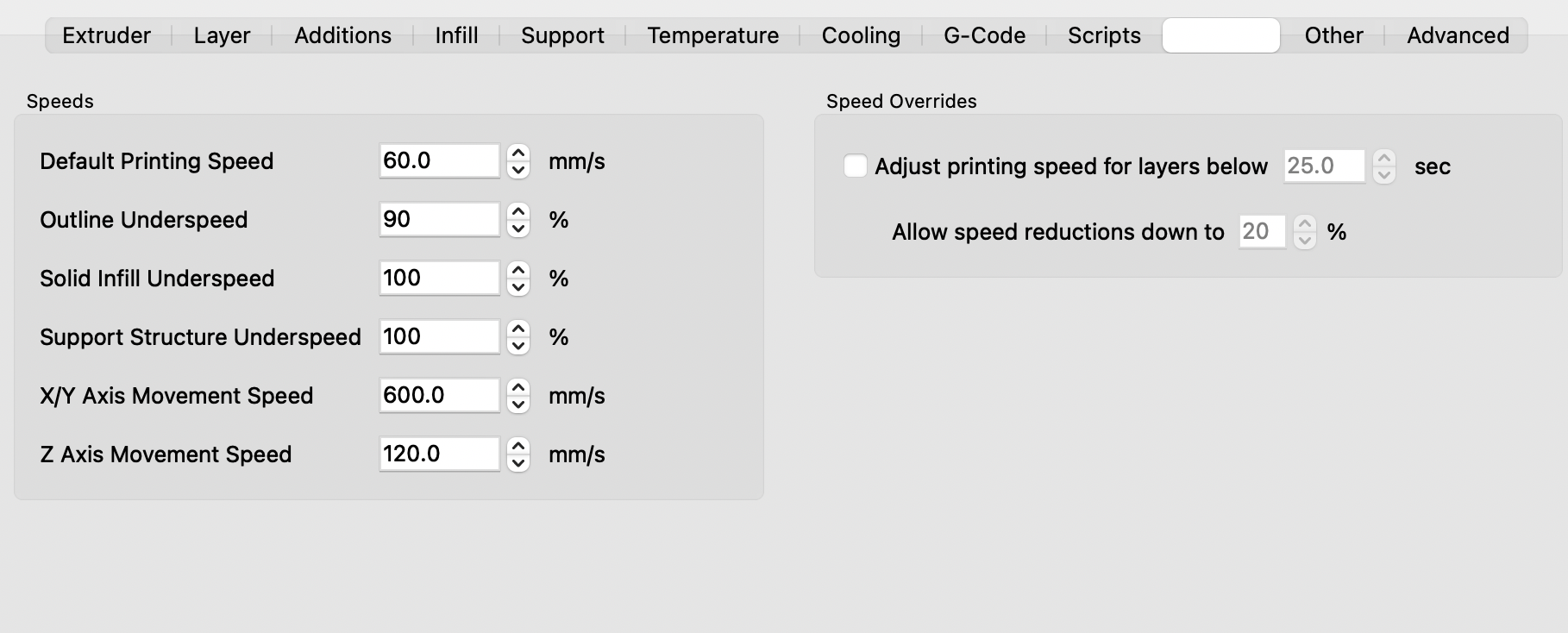

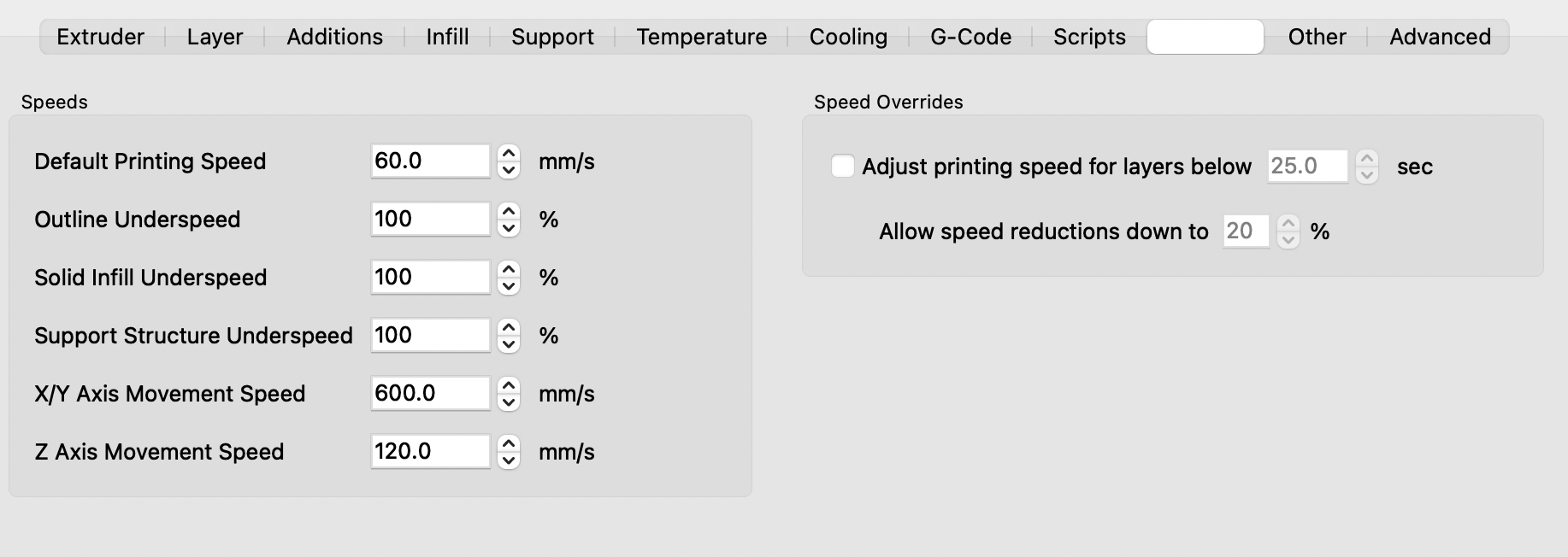

@jay_s_uk I run Simplify 3D and the only speed settings I can see that might affect it is the "adjust printing speed for layers below BLANK" and that doesn't seem to be the culprit. I have all of my speeds adjusted as such:

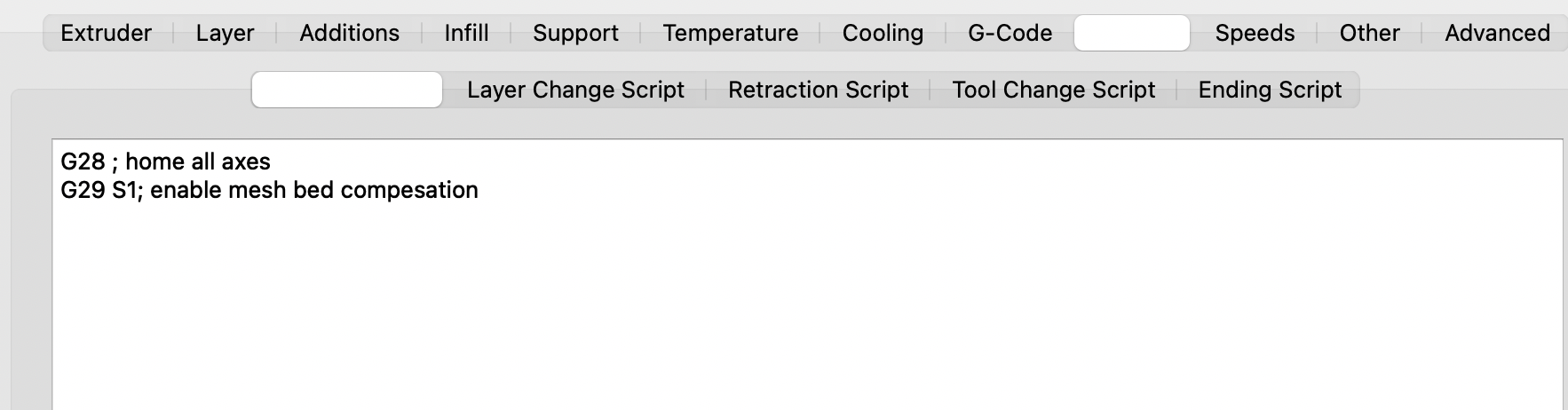

I don't see anywhere in the gcode where my prints are being slowed. Here's an example of the beginning code of one of my gcode files:

G90

M82

M106 S0

M140 S90

M190 S90

M104 S245 T0

M109 S245 T0

G28 ; home all axes

G29 S1; enable mesh bed compesation

; process VoronPETG1.18.245.60.Vase

; layer 1, Z = 1.000

T0

G92 E0.0000

G1 E-6.5000 F2400

; feature skirt

; tool H1.000 W2.000

G1 Z1.000 F7200

G1 X161.678 Y154.050 F36000

G1 E0.0000 F2400

G92 E0.0000

G1 X161.825 Y153.921 E0.1600 F673

G1 X162.449 Y153.442 E0.8009

G1 X162.612 Y153.333 E0.9609I wonder if my microstepping coupled with MeshBed compensation has anything to do with it?

(see my config)

Thanks so much,

Chris -

@jay_s_uk I run Simplify 3D and they way I understand it, Minimum Layer Time isn't an option, rather they use the "adjust printing speed for layers below BLANK seconds".

-

@christockos again, that looks acceptable. The first few lines show a move just over 61mm/s.

Do you have a start.g? -

Yeah, nothing suspicious as far as I can tell.

-

@christockos I meant on the duet board

-

@jay_s_uk I do not have a start.g (at least when I look in the system, where the config.g file lives).

-

@christockos said in Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow:

G1 X161.678 Y154.050 F36000

That's a requested travel speed of 600mm/sec, which is nice and high. Your M203 settings may be lower than that, in which case the MN203 settings will be used.

G1 X161.825 Y153.921 E0.1600 F673

That's a requested printing speed of 11.2mm/sec for the skirt. Much slower!

I had a similar issue when I switched to PrusaSlicer. That slicer multiplies a number of factors together to get the requested printing speed. Starting with the default printing speed it multiplies it by a percentage for the move type (e.g. perimeter, external perimeter, small perimeter, solid infill, skirt) and then by the first layer speed perecentage. In order to get a decent print speed from my delta, I had to increase the print speeds and factors.

Your acceleration limits will also limit the print speed for short moves.

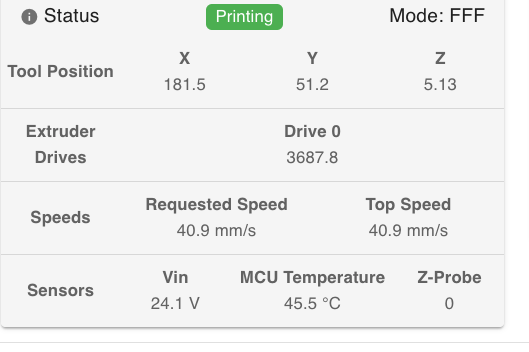

I suggest you watch the "Requested speed" and "Top speed" displayed by DWC while it is printing. If the move is slow but those figures are equal then the issue is with the slicer settings. OTOH if the top speed is lower than the requested speed then the speed is being limited by the acceleration and move length (for straight moves) or by the configured jerk limit (for curves).

-

@dc42 Okay, I've done some troubleshooting (after updating to 3.4.2-rc2) and even though I have my speed in Simplify 3d set to 60mm/s:

and my first layer speed at 100%, my printer's 'requested speed' and 'top speed' both max out at 24.5mm/s.

I don't see anything else in Simplify3D where I would be slowing my print down to less than 50%.

It seems that "If the move is slow but those figures are equal then the issue is with the slicer settings" is the case, but I can't seem to find where the issue lies.

Confounding.

Thanks for any thoughts,

Chris -

@christockos FWIW, here's the start of a Simplify 3D generated gcode file:

; G-Code generated by Simplify3D(R) Version 4.1.2

; Aug 23, 2022 at 4:43:35 PM

; Settings Summary

; processName,VoronPETG1.18.245.60.Vase

; applyToModels,Block4VaseMode092002

; profileName,Voron2.4.3x350 (modified)

; profileVersion,2022-08-08 14:20:07

; baseProfile,Default

; printMaterial,PETG

; printQuality,Medium

; printExtruders,

; extruderName,Extruder 1

; extruderToolheadNumber,0

; extruderDiameter,1.8

; extruderAutoWidth,0

; extruderWidth,2

; extrusionMultiplier,0.98

; extruderUseRetract,1

; extruderRetractionDistance,6.5

; extruderExtraRestartDistance,0

; extruderRetractionZLift,0.5

; extruderRetractionSpeed,2400

; extruderUseCoasting,0

; extruderCoastingDistance,0.2

; extruderUseWipe,0

; extruderWipeDistance,5

; primaryExtruder,0

; layerHeight,1

; topSolidLayers,0

; bottomSolidLayers,0

; perimeterOutlines,1

; printPerimetersInsideOut,0

; startPointOption,3

; startPointOriginX,0

; startPointOriginY,0

; sequentialIslands,0

; spiralVaseMode,1

; firstLayerHeightPercentage,100

; firstLayerWidthPercentage,100

; firstLayerUnderspeed,1

; useRaft,0

; raftExtruder,0

; raftTopLayers,3

; raftBaseLayers,2

; raftOffset,3

; raftSeparationDistance,0.14

; raftTopInfill,100

; aboveRaftSpeedMultiplier,0.3

; useSkirt,1

; skirtExtruder,0

; skirtLayers,1

; skirtOutlines,1

; skirtOffset,2

; usePrimePillar,0

; primePillarExtruder,999

; primePillarWidth,12

; primePillarLocation,7

; primePillarSpeedMultiplier,1

; useOozeShield,0

; oozeShieldExtruder,999

; oozeShieldOffset,2

; oozeShieldOutlines,1

; oozeShieldSidewallShape,1

; oozeShieldSidewallAngle,30

; oozeShieldSpeedMultiplier,1

; infillExtruder,0

; internalInfillPattern,Rectilinear

; externalInfillPattern,Concentric

; infillPercentage,0

; outlineOverlapPercentage,18

; infillExtrusionWidthPercentage,100

; minInfillLength,5

; infillLayerInterval,1

; internalInfillAngles,45,-45

; overlapInternalInfillAngles,0

; externalInfillAngles,45,-45

; generateSupport,0

; supportExtruder,0

; supportInfillPercentage,30

; supportExtraInflation,0

; supportBaseLayers,0

; denseSupportExtruder,0

; denseSupportLayers,0

; denseSupportInfillPercentage,70

; supportLayerInterval,1

; supportHorizontalPartOffset,0.3

; supportUpperSeparationLayers,1

; supportLowerSeparationLayers,1

; supportType,0

; supportGridSpacing,4

; maxOverhangAngle,45

; supportAngles,0

; temperatureName,Extruder 1,Heated Bed

; temperatureNumber,0,0

; temperatureSetpointCount,1,1

; temperatureSetpointLayers,1,1

; temperatureSetpointTemperatures,245,90

; temperatureStabilizeAtStartup,1,1

; temperatureHeatedBed,0,1

; fanLayers,1,2

; fanSpeeds,0,100

; blipFanToFullPower,0

; adjustSpeedForCooling,0

; minSpeedLayerTime,25

; minCoolingSpeedSlowdown,20

; increaseFanForCooling,0

; minFanLayerTime,45

; maxCoolingFanSpeed,100

; increaseFanForBridging,0

; bridgingFanSpeed,100

; use5D,1

; relativeEdistances,0

; allowEaxisZeroing,1

; independentExtruderAxes,0

; includeM10123,0

; stickySupport,1

; applyToolheadOffsets,0

; gcodeXoffset,0

; gcodeYoffset,0

; gcodeZoffset,0

; overrideMachineDefinition,1

; machineTypeOverride,0

; strokeXoverride,350

; strokeYoverride,350

; strokeZoverride,350

; originOffsetXoverride,0

; originOffsetYoverride,0

; originOffsetZoverride,0

; homeXdirOverride,-1

; homeYdirOverride,-1

; homeZdirOverride,-1

; flipXoverride,1

; flipYoverride,-1

; flipZoverride,1

; toolheadOffsets,0,0|0,0|0,0|0,0|0,0|0,0

; overrideFirmwareConfiguration,1

; firmwareTypeOverride,RepRap (Marlin/Repetier/Sprinter)

; GPXconfigOverride,r2

; baudRateOverride,115200

; overridePrinterModels,0

; printerModelsOverride

; startingGcode,G28 ; home all axes,G29 S1; enable mesh bed compesation

; layerChangeGcode,

; retractionGcode,

; toolChangeGcode,

; endingGcode,M104 S0 ; turn off extruder,M140 S0 ; turn off bed,G28 XY,M84 ; disable motors

; exportFileFormat,gcode

; celebration,0

; celebrationSong,Random Song

; postProcessing,

; defaultSpeed,3600

; outlineUnderspeed,1

; solidInfillUnderspeed,1

; supportUnderspeed,1

; rapidXYspeed,36000

; rapidZspeed,7200

; minBridgingArea,50

; bridgingExtraInflation,0

; bridgingExtrusionMultiplier,1

; bridgingSpeedMultiplier,1

; useFixedBridgingAngle,0

; fixedBridgingAngle,0

; applyBridgingToPerimeters,0

; filamentDiameters,1.75|1.75|1.75|1.75|1.75|1.75

; filamentPricesPerKg,46|46|46|46|46|46

; filamentDensities,1.25|1.25|1.25|1.25|1.25|1.25

; useMinPrintHeight,0

; minPrintHeight,0

; useMaxPrintHeight,0

; maxPrintHeight,0

; useDiaphragm,0

; diaphragmLayerInterval,20

; robustSlicing,1

; mergeAllIntoSolid,0

; onlyRetractWhenCrossingOutline,1

; retractBetweenLayers,1

; useRetractionMinTravel,0

; retractionMinTravel,3

; retractWhileWiping,0

; onlyWipeOutlines,1

; avoidCrossingOutline,0

; maxMovementDetourFactor,3

; toolChangeRetractionDistance,12

; toolChangeExtraRestartDistance,-0.5

; toolChangeRetractionSpeed,600

; externalThinWallType,1

; internalThinWallType,2

; thinWallAllowedOverlapPercentage,10

; singleExtrusionMinLength,1

; singleExtrusionMinPrintingWidthPercentage,50

; singleExtrusionMaxPrintingWidthPercentage,200

; singleExtrusionEndpointExtension,0.2

; horizontalSizeCompensation,0

G90

M82

M106 S0

M140 S90

M190 S90

M104 S245 T0

M109 S245 T0

G28 ; home all axes

G29 S1; enable mesh bed compesation

; process VoronPETG1.18.245.60.Vase

; layer 1, Z = 1.000

T0

G92 E0.0000

G1 E-6.5000 F2400

; feature skirt

; tool H1.000 W2.000

G1 Z1.000 F7200

G1 X161.678 Y154.050 F36000 -

@christockos said in Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow:

I'm printing with a Misquito Magnum 1.8mm nozzle, 2.0mm Extrusion width, 1mm layer height.

At 25mm/s this is a flow of about 50mm^3, right?

According to this post by Slice, 38mm^3 is pushing it. What speed and flow rate do you hope to achieve?

https://support.sliceengineering.com/portal/en/community/topic/mosquito-magnum-petg-max-flow-rate

-

@christockos ah, your extruder speed limit is set to 1200mm/min, or 20mm/s, which for a 1.75mm dia filament, means the max flow it can achieve is 48mm3/s (I.e. what @zapta calculated!).

If you want to push it harder, increase your E speed in your M203 command, but that is really pushing a lot of plastic, so the hotend may not be able to print much more!

-

@engikeneer said in Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow:

increase your E speed in your M203

Yup, that's it. I cranked my M203 setting to 2000mm/min and got this:

Mystery solved, thanks everyone!

-

@christockos How do I mark this as 'Solved'?

-

Click on the Topic Tools icon (the little gear) and select "ask as question". Then click on it again and select "mark as solved".

-

undefined Christockos marked this topic as a question

undefined Christockos marked this topic as a question

-

undefined Christockos has marked this topic as solved

undefined Christockos has marked this topic as solved