Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow

-

@christockos again, that looks acceptable. The first few lines show a move just over 61mm/s.

Do you have a start.g? -

Yeah, nothing suspicious as far as I can tell.

-

@christockos I meant on the duet board

-

@jay_s_uk I do not have a start.g (at least when I look in the system, where the config.g file lives).

-

@christockos said in Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow:

G1 X161.678 Y154.050 F36000

That's a requested travel speed of 600mm/sec, which is nice and high. Your M203 settings may be lower than that, in which case the MN203 settings will be used.

G1 X161.825 Y153.921 E0.1600 F673

That's a requested printing speed of 11.2mm/sec for the skirt. Much slower!

I had a similar issue when I switched to PrusaSlicer. That slicer multiplies a number of factors together to get the requested printing speed. Starting with the default printing speed it multiplies it by a percentage for the move type (e.g. perimeter, external perimeter, small perimeter, solid infill, skirt) and then by the first layer speed perecentage. In order to get a decent print speed from my delta, I had to increase the print speeds and factors.

Your acceleration limits will also limit the print speed for short moves.

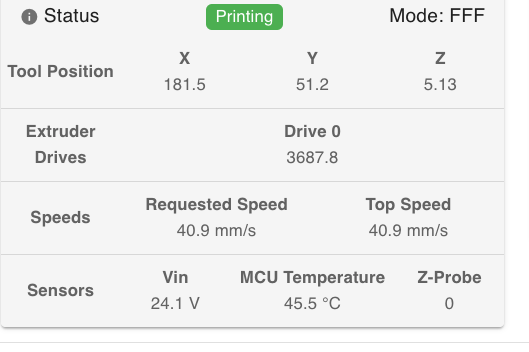

I suggest you watch the "Requested speed" and "Top speed" displayed by DWC while it is printing. If the move is slow but those figures are equal then the issue is with the slicer settings. OTOH if the top speed is lower than the requested speed then the speed is being limited by the acceleration and move length (for straight moves) or by the configured jerk limit (for curves).

-

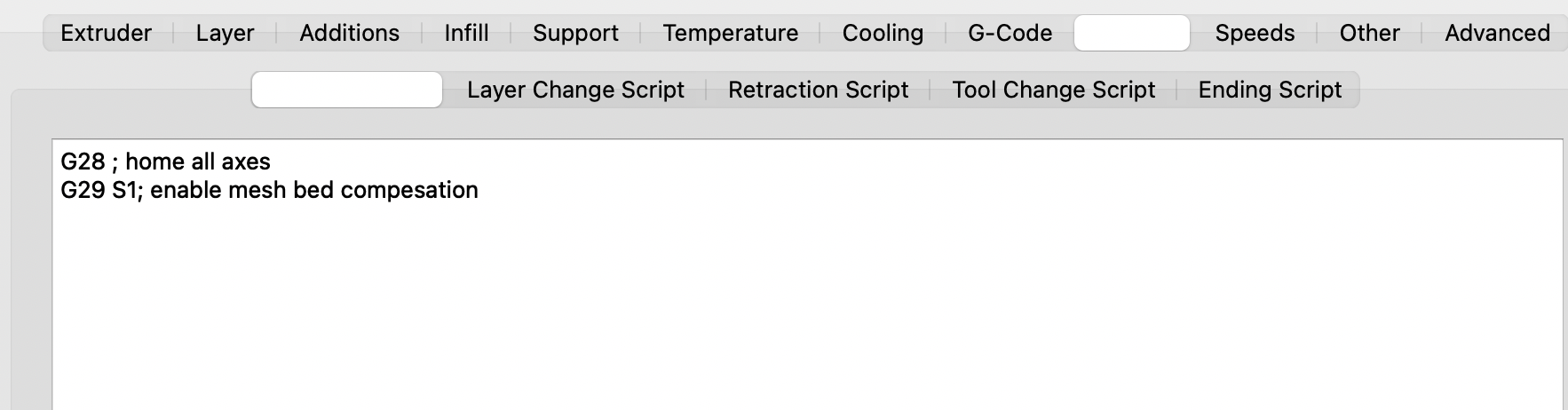

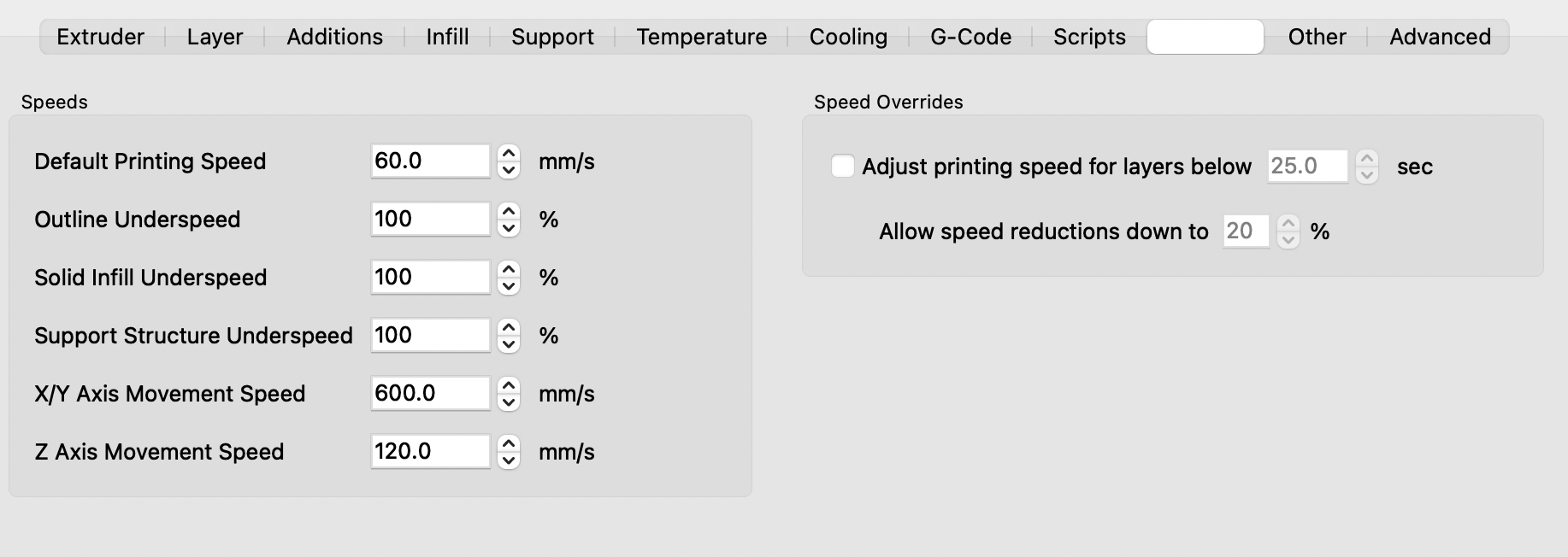

@dc42 Okay, I've done some troubleshooting (after updating to 3.4.2-rc2) and even though I have my speed in Simplify 3d set to 60mm/s:

and my first layer speed at 100%, my printer's 'requested speed' and 'top speed' both max out at 24.5mm/s.

I don't see anything else in Simplify3D where I would be slowing my print down to less than 50%.

It seems that "If the move is slow but those figures are equal then the issue is with the slicer settings" is the case, but I can't seem to find where the issue lies.

Confounding.

Thanks for any thoughts,

Chris -

@christockos FWIW, here's the start of a Simplify 3D generated gcode file:

; G-Code generated by Simplify3D(R) Version 4.1.2

; Aug 23, 2022 at 4:43:35 PM

; Settings Summary

; processName,VoronPETG1.18.245.60.Vase

; applyToModels,Block4VaseMode092002

; profileName,Voron2.4.3x350 (modified)

; profileVersion,2022-08-08 14:20:07

; baseProfile,Default

; printMaterial,PETG

; printQuality,Medium

; printExtruders,

; extruderName,Extruder 1

; extruderToolheadNumber,0

; extruderDiameter,1.8

; extruderAutoWidth,0

; extruderWidth,2

; extrusionMultiplier,0.98

; extruderUseRetract,1

; extruderRetractionDistance,6.5

; extruderExtraRestartDistance,0

; extruderRetractionZLift,0.5

; extruderRetractionSpeed,2400

; extruderUseCoasting,0

; extruderCoastingDistance,0.2

; extruderUseWipe,0

; extruderWipeDistance,5

; primaryExtruder,0

; layerHeight,1

; topSolidLayers,0

; bottomSolidLayers,0

; perimeterOutlines,1

; printPerimetersInsideOut,0

; startPointOption,3

; startPointOriginX,0

; startPointOriginY,0

; sequentialIslands,0

; spiralVaseMode,1

; firstLayerHeightPercentage,100

; firstLayerWidthPercentage,100

; firstLayerUnderspeed,1

; useRaft,0

; raftExtruder,0

; raftTopLayers,3

; raftBaseLayers,2

; raftOffset,3

; raftSeparationDistance,0.14

; raftTopInfill,100

; aboveRaftSpeedMultiplier,0.3

; useSkirt,1

; skirtExtruder,0

; skirtLayers,1

; skirtOutlines,1

; skirtOffset,2

; usePrimePillar,0

; primePillarExtruder,999

; primePillarWidth,12

; primePillarLocation,7

; primePillarSpeedMultiplier,1

; useOozeShield,0

; oozeShieldExtruder,999

; oozeShieldOffset,2

; oozeShieldOutlines,1

; oozeShieldSidewallShape,1

; oozeShieldSidewallAngle,30

; oozeShieldSpeedMultiplier,1

; infillExtruder,0

; internalInfillPattern,Rectilinear

; externalInfillPattern,Concentric

; infillPercentage,0

; outlineOverlapPercentage,18

; infillExtrusionWidthPercentage,100

; minInfillLength,5

; infillLayerInterval,1

; internalInfillAngles,45,-45

; overlapInternalInfillAngles,0

; externalInfillAngles,45,-45

; generateSupport,0

; supportExtruder,0

; supportInfillPercentage,30

; supportExtraInflation,0

; supportBaseLayers,0

; denseSupportExtruder,0

; denseSupportLayers,0

; denseSupportInfillPercentage,70

; supportLayerInterval,1

; supportHorizontalPartOffset,0.3

; supportUpperSeparationLayers,1

; supportLowerSeparationLayers,1

; supportType,0

; supportGridSpacing,4

; maxOverhangAngle,45

; supportAngles,0

; temperatureName,Extruder 1,Heated Bed

; temperatureNumber,0,0

; temperatureSetpointCount,1,1

; temperatureSetpointLayers,1,1

; temperatureSetpointTemperatures,245,90

; temperatureStabilizeAtStartup,1,1

; temperatureHeatedBed,0,1

; fanLayers,1,2

; fanSpeeds,0,100

; blipFanToFullPower,0

; adjustSpeedForCooling,0

; minSpeedLayerTime,25

; minCoolingSpeedSlowdown,20

; increaseFanForCooling,0

; minFanLayerTime,45

; maxCoolingFanSpeed,100

; increaseFanForBridging,0

; bridgingFanSpeed,100

; use5D,1

; relativeEdistances,0

; allowEaxisZeroing,1

; independentExtruderAxes,0

; includeM10123,0

; stickySupport,1

; applyToolheadOffsets,0

; gcodeXoffset,0

; gcodeYoffset,0

; gcodeZoffset,0

; overrideMachineDefinition,1

; machineTypeOverride,0

; strokeXoverride,350

; strokeYoverride,350

; strokeZoverride,350

; originOffsetXoverride,0

; originOffsetYoverride,0

; originOffsetZoverride,0

; homeXdirOverride,-1

; homeYdirOverride,-1

; homeZdirOverride,-1

; flipXoverride,1

; flipYoverride,-1

; flipZoverride,1

; toolheadOffsets,0,0|0,0|0,0|0,0|0,0|0,0

; overrideFirmwareConfiguration,1

; firmwareTypeOverride,RepRap (Marlin/Repetier/Sprinter)

; GPXconfigOverride,r2

; baudRateOverride,115200

; overridePrinterModels,0

; printerModelsOverride

; startingGcode,G28 ; home all axes,G29 S1; enable mesh bed compesation

; layerChangeGcode,

; retractionGcode,

; toolChangeGcode,

; endingGcode,M104 S0 ; turn off extruder,M140 S0 ; turn off bed,G28 XY,M84 ; disable motors

; exportFileFormat,gcode

; celebration,0

; celebrationSong,Random Song

; postProcessing,

; defaultSpeed,3600

; outlineUnderspeed,1

; solidInfillUnderspeed,1

; supportUnderspeed,1

; rapidXYspeed,36000

; rapidZspeed,7200

; minBridgingArea,50

; bridgingExtraInflation,0

; bridgingExtrusionMultiplier,1

; bridgingSpeedMultiplier,1

; useFixedBridgingAngle,0

; fixedBridgingAngle,0

; applyBridgingToPerimeters,0

; filamentDiameters,1.75|1.75|1.75|1.75|1.75|1.75

; filamentPricesPerKg,46|46|46|46|46|46

; filamentDensities,1.25|1.25|1.25|1.25|1.25|1.25

; useMinPrintHeight,0

; minPrintHeight,0

; useMaxPrintHeight,0

; maxPrintHeight,0

; useDiaphragm,0

; diaphragmLayerInterval,20

; robustSlicing,1

; mergeAllIntoSolid,0

; onlyRetractWhenCrossingOutline,1

; retractBetweenLayers,1

; useRetractionMinTravel,0

; retractionMinTravel,3

; retractWhileWiping,0

; onlyWipeOutlines,1

; avoidCrossingOutline,0

; maxMovementDetourFactor,3

; toolChangeRetractionDistance,12

; toolChangeExtraRestartDistance,-0.5

; toolChangeRetractionSpeed,600

; externalThinWallType,1

; internalThinWallType,2

; thinWallAllowedOverlapPercentage,10

; singleExtrusionMinLength,1

; singleExtrusionMinPrintingWidthPercentage,50

; singleExtrusionMaxPrintingWidthPercentage,200

; singleExtrusionEndpointExtension,0.2

; horizontalSizeCompensation,0

G90

M82

M106 S0

M140 S90

M190 S90

M104 S245 T0

M109 S245 T0

G28 ; home all axes

G29 S1; enable mesh bed compesation

; process VoronPETG1.18.245.60.Vase

; layer 1, Z = 1.000

T0

G92 E0.0000

G1 E-6.5000 F2400

; feature skirt

; tool H1.000 W2.000

G1 Z1.000 F7200

G1 X161.678 Y154.050 F36000 -

@christockos said in Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow:

I'm printing with a Misquito Magnum 1.8mm nozzle, 2.0mm Extrusion width, 1mm layer height.

At 25mm/s this is a flow of about 50mm^3, right?

According to this post by Slice, 38mm^3 is pushing it. What speed and flow rate do you hope to achieve?

https://support.sliceengineering.com/portal/en/community/topic/mosquito-magnum-petg-max-flow-rate

-

@christockos ah, your extruder speed limit is set to 1200mm/min, or 20mm/s, which for a 1.75mm dia filament, means the max flow it can achieve is 48mm3/s (I.e. what @zapta calculated!).

If you want to push it harder, increase your E speed in your M203 command, but that is really pushing a lot of plastic, so the hotend may not be able to print much more!

-

@engikeneer said in Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow:

increase your E speed in your M203

Yup, that's it. I cranked my M203 setting to 2000mm/min and got this:

Mystery solved, thanks everyone!

-

@christockos How do I mark this as 'Solved'?

-

Click on the Topic Tools icon (the little gear) and select "ask as question". Then click on it again and select "mark as solved".

-

undefined Christockos marked this topic as a question

undefined Christockos marked this topic as a question

-

undefined Christockos has marked this topic as solved

undefined Christockos has marked this topic as solved