Heating fault on heater 1

-

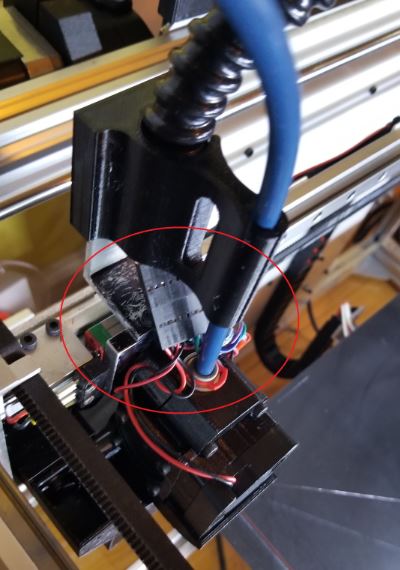

I check the wire lastnight and the only joint conection point it at the hot end, I have servo plug the connect the wire. I order new thermistor/heater. I am using E3D (V6) Hotend. Both T0 and T1 have the same type of connection servo plug.

-

What is the actual heater fault? What did the error say?

-

The first time was, Error: Heating fault on heater 1, temperature rising much more slowly than the expected 1.8°C/sec

Now is just a pop up box, saying Heating fault on heater 1.

-

Check that the thermistor and heater cartridge are firmly inside the heater block. Tighten the grub screw and clamping screw.

-

Thermistor and heater cartridge are firmly inside the heater block, I think it's the connection I made is the problem, I redo with new connectors, I am trying the print again, will update tomorrow.

-

I struggled with a similar heater fault for months. It would work for awhile and then fail. Everyone is saying to you the same thing they advised me. CHECK THAT WIRING because while I did check it again and again and found it to be ok, it was the cause!! Now my heater fault is gone. Can you RESET the fault using

macro: reset_heat_fault

; file: reset_heat_fault macro, 3mm, 06-03-2018

M562 P1 ; reset nozzle heater fault statusSee if that will reset the fault.

But check that wiring and as Phaedrux says check the heat cartridge and thermistor is seated well. I use high temperature thermal compound aroung my thermistors.

good luck...3mm

-

Another thing to check is your M143 temperature limit.

I had set that limit to low for one tool (245) and when I wanted to print at 240 the heater was overshooting its limit sometimes by a small value like 1 or 2 degree. Setting the limit to 248 fixed it for me. -

Have you read the wiki page on spurious heater faults?

Did you run heater tuning, and save the values from it? Send M307 H1 to check what heater model parameters are being used.

When the heater fault occurs, what error message does it give on the console?

-

Ok, guys think I found the source of the problem. The connector that I made for the T0 was not tight so it was shaking when printing which creates a short inside the connector. So after about 6 hours of printing everything looks good.

Finish Print

I need to calibrate my extruders and Tune cura.

Cura

Polymaker 2.85mm PolyLite PLA Filament Translucent

.6 Nozzle

.3 Layer Height

10% Infill.

This was print at 150% scale.

https://www.thingiverse.com/thing:2849214

The Hotend (T0) Connections. This shows the new connector.

-

Thanks, I'll mark this as solved.