Homeall.g fails when homing all axes

-

@fcwilt said in Homeall.g fails when homing all axes:

What is your thinking on having those two endstops?

You are aware that endstops serve no purpose except during G1 H1 or G1 H3 or G1 H4 moves?

Just having a single endstop at the min Y-axis. Since only 1 Single Endstop is allowed , by connecting the 2 physical endstops (at minimum) together to act as only a single endpoint at minimum

-

@developeralgo222 if you really want to use 2 Y endstops even though you have just 1 Y motor, then my interpretation of the datasheet you linked to is that you need to use the white wire as the output connected to the iox_in pin (not the black wire), connect both sensors in parallel, and use the ! character at the start of the pin name.

You can activate the endstops manually (i.e. place a piece pf card in the slot) and use the Object Model Browser in DWC to check that activating either endstop changes the state of the endstop in the object mode to triggered.

-

@developeralgo222 said in Homeall.g fails when homing all axes:

@fcwilt

wasn't aware of that . So really, what's the value-added in having endstops anyway in duet ? since they seem to be integral part in some Duet's movement process. I am confused about your statementWhen you first power on a machine (or after any reset) the physical position of each axis is unknown.

The homing processes use G1 H1 moves and the action of the axis endstops to determine the actual physical position and thus sync the logical position with the physical position.

The position of the endstop must be near one end of the axis and must work in such away that it is not possible to obtain a physical position past the endstop where the endstop is not activated.

The G1 H1 moves allow stopping motion when the endstop is triggered. Since the location of the endstop is known (indeed it must be known) once the G1 H1 move is stopped the physical position of the axis is known and the the logical position of the axis (the value you see on the DWC) can be synced with the actual physical position.

Once the logical and physical are in sync normal G90 G1 moves can move to any point on the axis (within the min/max range) with a good deal of accuracy.

IF the endstop triggered at exactly the min or max of the axis (depending on where the endstop was) the G1 H1 move would establish BOTH the axis physical and logical position simultaneously.

However, I have never had a printer where that was true and it has always required a bit of additional code in the homing routine to sync the physical and logical positions.

Frederick

-

-

You can install two Y endstop sensors but you are not going to derive any benefit from doing so, when you only have one Y stepper motor.

Frederick

-

@developeralgo222 for Y axis and white wires use !iox.in

-

Just leaving 2 endstops at the Min of each rail . The 2 endstops are connected as a 1 single Endstop at the Min only. Will this work for Y-axis?

Yes - because, as you rightly say, the two endstops are wired to act as a single switch.

-

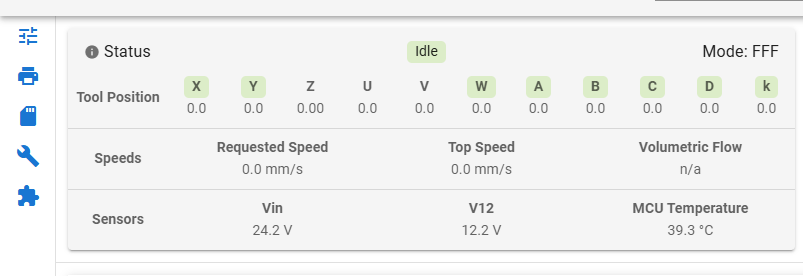

Ok i have made the modifications on Endstops

X-Axis ---- Endstop works fine now and triggers correctly

Y-Axis ---- Endstop works fine now and triggers correctly

W, A, B, C, D, k ---- Endstop works fine now and triggers correctly

Test:

Working on Z, U , V Axes:

Not sure how this need to be configured ( This are shared Z-CAM based axis ) for 6 Nozzles

Z , U , V ( Z-Axis = (Z1, Z2), U-Axis = (Z3, Z4), V-Axis= (Z5, Z6) ) only Z2 , Z4, Z6 triggers Z , U , V respectively but not Z1, Z3, Z5

; Endstops ; For X and Y Axis M574 X1 S1 P"0.io1.in" ; configure active high endstop switch for low end on X via pin io1.in M574 Y1 S1 P"0.io2.in" ; configure active high endstop switch for low end on Y via pin io2.in ; For Z-Axis (Shared Z,U,V) - Up/down) -- CAM Driven Dual Nozzles ( 1 Motor rotates up/down to drive 2 Nozzles ) M574 Z1 S1 P"1.io0.in" ; configure active high endstop switch for low end on Z via pin 1.io0.in M574 Z2 S1 P"1.io1.in" ; configure active high endstop switch for High end on Z via pin 1.io1.in M574 U1 S1 P"1.io2.in" ; configure active high endstop switch for low end on U via pin 1.io2.in M574 U2 S1 P"1.io3.in" ; configure active high endstop switch for High end on U via pin 1.io3.in M574 V1 S1 P"1.io4.in" ; configure active high endstop switch for low end on V via pin 1.io4.in M574 V2 S1 P"1.io5.in" ; configure active high endstop switch for High end on V via pin 1.io5.in ; For Rotational Axes only (W, A, B, C, D, 'k(k)) M574 W1 S1 P"2.io3.in" ; configure active high endstop switch for low end on W via pin 2.io3.in M574 A1 S1 P"2.io4.in" ; configure active high endstop switch for low end on A via pin 2.io4.in M574 B1 S1 P"2.io5.in" ; configure active high endstop switch for low end on B via pin 2.io5.in M574 C1 S1 P"3.io3.in" ; configure active high endstop switch for low end on C via pin 3.io3.in M574 D1 S1 P"3.io4.in" ; configure active high endstop switch for low end on D via pin 3.io4.in M574 'k1 S1 P"3.io5.in" ; configure active high endstop switch for low end on 'k via pin 3.io5.inHere is a photo of the 6-Nozzles with a little grainy photo to show some of the 6 endstops under each Z-based axis ( Z, U, V )

-

@developeralgo222

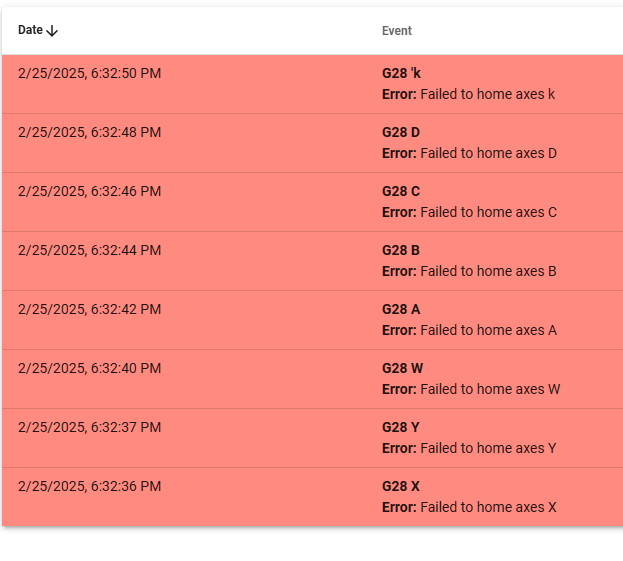

i went back to try and individually home all Axes that have their end stops corrected i.eX-Axis ---- End stop works fine now and triggers correctly

Y-Axis ---- End stop works fine now and triggers correctly

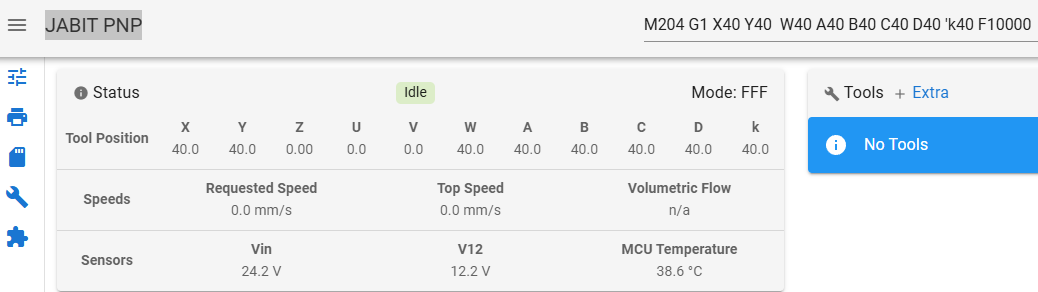

W, A, B, C, D, k ---- End stop works fine now and triggers correctlyHoming fails on all of them. e.g. homing X-axis, this is what i have in the file ( very simple, nothing complicated ). It completes the movements in homing X-axis fine with no issues but DWC reports that Homing X failed e.g

; Home X-Axis G91 ; relative positioning G1 H2 X0 ; set axes position explicitly to Zero i.e move X and Y-axis Minimum Homing endstop and stop there G1 H2 X40 F10000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-40 F10000 ; go back a few mm G1 H2 X0 ; move X and Y-axis Minimum Homing endstop and stop there (first pass) G90 ; absolute positioning

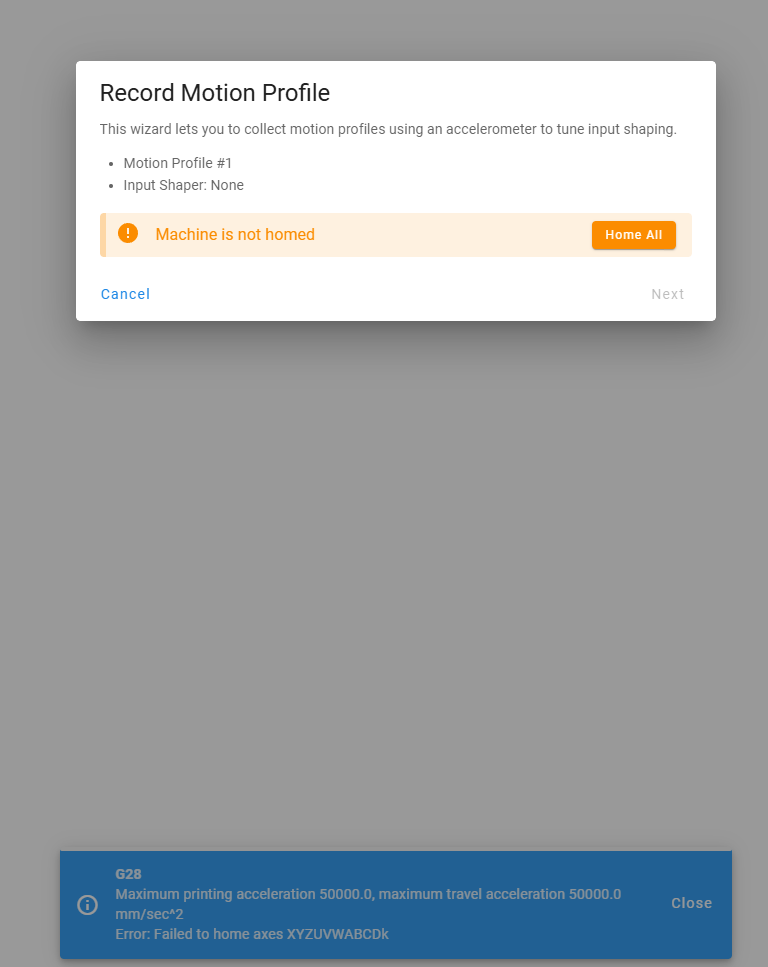

It affects me in that i can't use Input Shaping with Accelerometer from the DWC to help tune and optimize my PNP machine Speed and acceleration . Input Shaping from DWC is using HomeAll button . Not sure if its failing bacause of Z, U, V that have endstop issues

-

; Home X-Axis G91 ; relative positioning G1 H2 X0 ; set axes position explicitly to Zero i.e move X and Y-axis Minimum Homing endstop and stop there G1 H2 X40 F10000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-40 F10000 ; go back a few mm G1 H2 X0 ; move X and Y-axis Minimum Homing endstop and stop there (first pass) G90 ; absolute positioningG1 H2 doesn't do what you think it does here.

G1 H2 X0 means to do a zero movement move regardless if the axis is homed or not. G1 H2 moves are meant to leat you move the axis away from an endstop slightly before a homing move, or to raise the z axis before making an X Y move to prevent scraping.

An actual homing move is done with a G1 H1 movement which needs to be long enough to strike the endstop even from the farthest opposing position. It also must be in the direction of the endstop.

-

You are using H2 instead of H1.

You posted that the X endstop is at the low end.

I don't know how long the X axis is but you need something like...

G91 G1 H1 X-999 F5000 ; use a value large enough to move the entire length of the X axis G1 X10 G1 H1 X-15 F500...then based on what the physical position is when stopped by the endstop being triggered

G1 Xnnn ; move to some known position on the axis - note this is a relative move still G92 Xppp ; set the X axis logical position to match the physical positionFrederick

-

@fcwilt

X-axis = 340 mm and Y-axis = 447mm.I think i only have extra additional of -2.0516mm on X-axis on the low end and -4.0244mm on Y-axis

-

@developeralgo222 said in Homeall.g fails when homing all axes:

@fcwilt

X-axis = 340 mm and Y-axis = 447mm.I think i only have extra additional of -2.0516mm on X-axis on the low end and -4.0244mm on Y-axis

OK then your first G1 H1 move would be

G1 H1 X-345 F5000You can pick a speed (the F parameter) that works best for you - it's not critical but you can go too fast.

At what position does the X endstop trigger? Are you treating that as X=0?

Frederick

-

@fcwilt said in Homeall.g fails when homing all axes:

At what position does the X endstop trigger? Are you treating that as X=0?

Yes at X=0. Do i need to test this on the command console or just put them in a homing file and test on DWC ?

something like this on homex.g ?

G91 G1 H1 X-345 F5000 ; use a value large enough to move the entire length of the X axis G1 X10 G1 H1 X-15 F500 G1 X0 G92 X0 G90 -

@developeralgo222 said in Homeall.g fails when homing all axes:

As I mentioned if the endstop triggers at the end of the axis travel and you are treating that as X=0 then you don't need the following:

G1 Xnnn G92 XpppThey are ONLY needed when the endstop is not triggering at X=0

In your case this should work for you:

G91 G1 H1 X-345 F5000 G1 X10 G1 H1 X-15 F500Now if you have specified your X axis with M208 -170:170, meaning X=0 is at the center of the axis you could add the following:

G90 G1 X0 F5000 -

@fcwilt said in Homeall.g fails when homing all axes:

Now if you have specified your X axis with M208 -170:170, meaning X=0 is at the center of the axis you could add the following:

i have M208 X0:340 Y0:447

-

-

@developeralgo222 said in Homeall.g fails when homing all axes:

i have M208 X0:340 Y0:447

That is fine - you don't have to have X=0 at the center of the bed. Some folks just prefer it that way - I am one of them.

Frederick

-

@fcwilt

That worked for X &Y and Z , i am going through all the axes one-by-one following your insights .How do you configure the endstops of a shared z-axis cam based

i have to configure endstops for 6-Nozzles ( 2 Nozzles share a single Z-axis based Stepper motor ) so that they trigger correctly

i.e 3 Stepper Motors for Z, U, V axis but each axis shared with 2 nozzles each with a Z-axis type.

-

@developeralgo222 said in Homeall.g fails when homing all axes:

How do you configure the endstops of a shared z-axis cam based

i have to configure endstops for 6-Nozzles ( 2 Nozzles share a single Z-axis based Stepper motor ) so that they trigger correctly

i.e 3 Stepper Motors for Z, U, V axis but each axis shared with 2 nozzles each with a Z-axis type.

That is not a setup I have seen or heard of.

Does the "Z stepper" turn the cam to raise/lower the nozzle?

Does each nozzle have it's own endstop sensor?

Frederick