Beginner issue: storing Z-offset

-

@cosmowave said in Beginner issue: storing Z-offset:

@fcwilt said in Beginner issue: storing Z-offset:

How is that possible? Why doesn't the nozzle crash into the mirror when homing?

This will only be possible when the nozzle is outside of the bed (or additional mirror) when homing...

OK, that's fair enough for homing, but not for bed levelling or mesh levelling. (that's why fcwilt and me were confused)

-

Please understand, I have 3 bed surface options. The Mirror prints AMAZING. Perfectly flat, but it is thicker than the regular "buildtech" surface by 1.4mm. Likewize I bought a Energetic Flex plate which I believe is even thicker than the mirror. So, I will be switching between them. (The flex plate has a very textured surface).

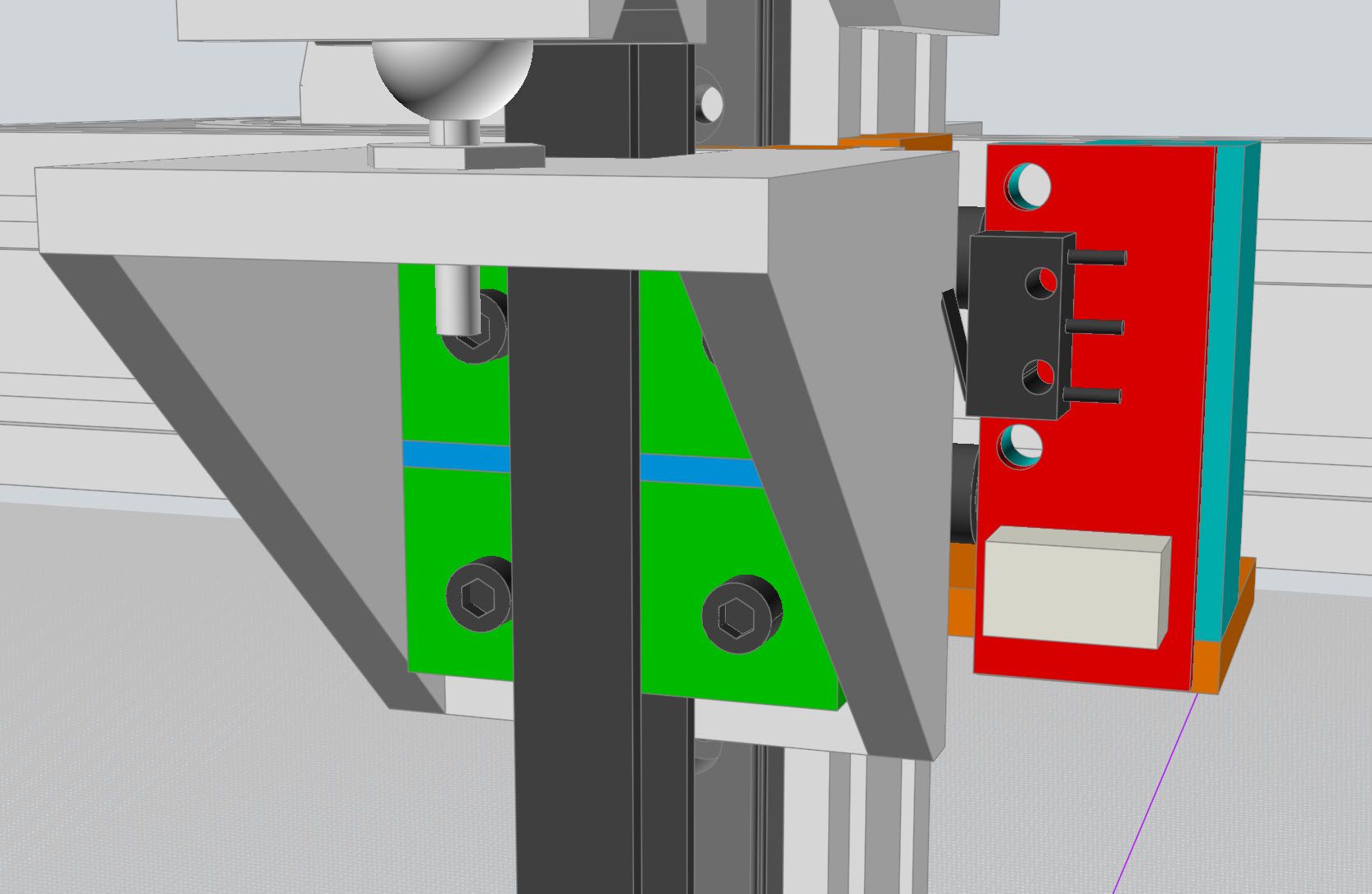

The mechanical endstop I don't want to move. If I moved it up, then physically I could never reach the bed (besides the Z min trigger)

This is actually very simple to set in Marlin with baby stepping and M500.

I'm perplexed that G92 isn't saved using M500 in RRF?

-

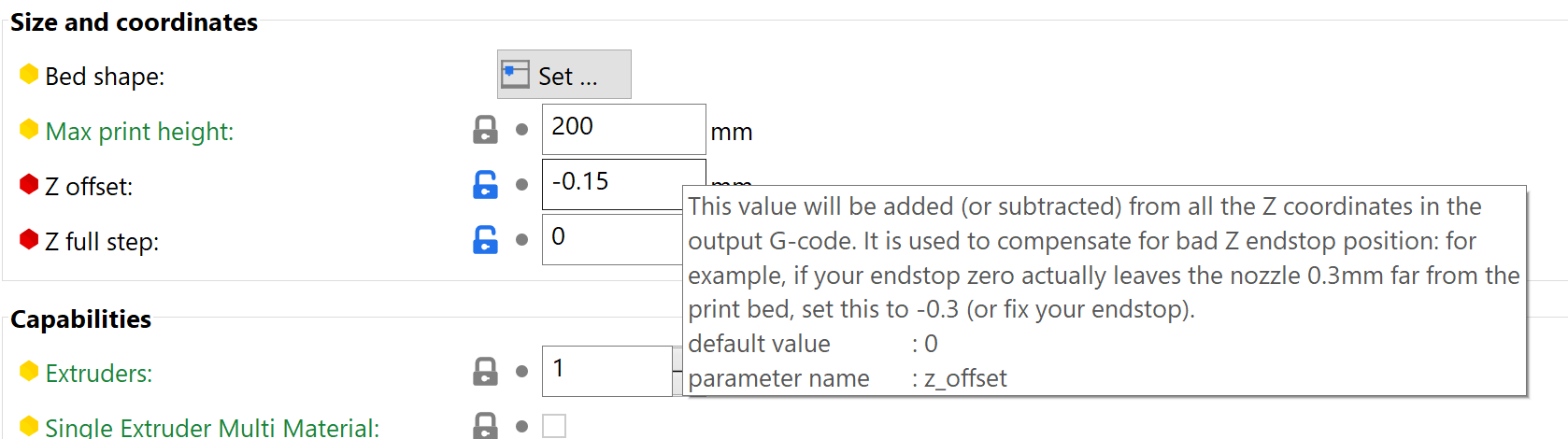

@westech I'm sure there are various ways of achieving this, but in my case where I have different z offsets per print surface I use the Z offset feature in my slicer profile.

I choose the thickest surface option to be the default (eg 0 z offset in the slicer) slicer profile and set printer firmware defaults (homing heights, offsets etc) for that print surface; then create different printer profiles for each additional print surface, and adjust the slicer z offset for each as required.

I just have to remember to choose the correct printer profile for the appropriate print surface before slicing.

(I am using a BL Touch so I do not have to worry about crashing the HE into the bed if the surface is not detectable with a inductive probe though.)

Hope this helps.

-

@westech said in Beginner issue: storing Z-offset:

The mechanical endstop I don't want to move. If I moved it up, then physically I could never reach the bed (besides the Z min trigger)

Well it doesn't have to be that way.

The purpose of any endstop is to allow the firmware to establish that an axis is in a known position.

That position can be anywhere along the axis as long as the firmware can use the endstop to accurately and unequivocally determine that position.

Of course the endstop sensor has to be mounted in such a way as to allow this.

I use IR beam break sensors which allow me to place the endstop near one end of the axis without preventing movement to the end of the axis.

For example on a recent printer I built the Z endstop sensor triggers at Z=20mm and remains triggered from 20mm to 0mm.

So the homing code looks something like this:

G91 G1 H1 Z-299 F3000 G1 Z25 G1 H1 Z-30 F300 G92 Z20 ; since the endstop sensor triggers at 20mm this is where the actual Z position is setIf I had to cope with different bed thicknesses I would set such an endstop sensor to trigger above the thickest bed and rely on the Z probe to establish the actual Z=0 datum for the current bed.

In your case you could use a global variable to hold the Z offset from the endstop sensor position for each bed type. A macro could set the Z offset for the current bed type. The homing code would use the value in the global variable with G92 to set the Z position so that Z=0 was at the surface of the current bed type.

Frederick

-

@westech said in Beginner issue: storing Z-offset:

I'm perplexed that G92 isn't saved using M500 in RRF?

G92 only sets the current position on an axis. It is not a constant value and thus cannot be saved in a meaningful way.

Frederick

-

@mintytrebor Thank you! I just checked Cura and Prusa Slicer and this is an excellent solution for me, unless I forget to switch the profiles.

Again, the enstop I have is a mechanical switch. It is physically impossible for the printer to go beyond the switch.

-

@westech said in Beginner issue: storing Z-offset:

Again, the enstop I have is a mechanical switch. It is physically impossible for the printer to go beyond the switch.

I understand that it is mounted in such a way on your printer that it is impossible to move beyond it.

But that is not an inherent characteristic of a mechanical switch.

I have micro-switches (the kind with a lever) that are mounted on the Z axis in such a way that they are triggered over a range and do not block movement.

Once the bed support bracket reaches the point where it triggers the switch the lever of the switch can just slide along the side.

Frederick

-

x; Z-Probe

M950 S0 C"servo0" ; create servo pin 0 for BLTouch

M558 P9 C"^probe" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-40 Y-12 Z2.08 ; set Z probe trigger value, offset and trigger height

M557 X15:215 Y15:195 S20 ; define mesh grIt looks like you have a BLTouch configured, but you're not using it in your homing files to actually probe and set the Z0 position. Doing this would solve all your problems and you don't have to worry about setting a Z offset or saving an offset, etc. You just measure the offset between the nozzle and probe trigger point once, save it, and you're good to go regardless of the bed surface because the probe checks the surface each time before the print when you home.

Do you not actually have a probe?

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

-

@westech said in Beginner issue: storing Z-offset:

This is actually very simple to set in Marlin with baby stepping and M500.

I'm perplexed that G92 isn't saved using M500 in RRF?That's a very marlin way of thinking.

You can use M500 P31 to save a trigger height for your probe (G31 Z) after it's been measured, but you can't save G92. That doesn't really make any sense. You don't need to save it because your homeall.g dictates what happens when you want to set the Z position. So just have G92 Z in there if you want to force a current position as Z#

-

@westech said in Beginner issue: storing Z-offset:

2) I use Cura, And for some weird reason at the end of the print the filament retracted a good 6-7". It's not in my Cura G-code because I print the same thing on another printer running Marlin. Any Thoughts.

You need to change Cura to use relative extrusion in the settings. It's likely set to absolute extrusion right now, and your end gcode probably has it do a small retraction, but since it's in absolute mode, it's not retracting a 2mm, it's going to the 2mm position which was way at the beginning of the print.

-

@phaedrux Greetings! Great feedback.

In reverse order. That weird Cura retraction only happened that one time. It could have been because Cura was set as MARLIN not RRF? All good now.

Please understand my approach. This is a new Ender 3. With Mellow Fly E3 running latest RRF. I'm not familiar with RRF. So, I move slowly adding new features. I Auto PID my hot end/bed. Tram my bed. Then dial in my Z height.

I do have a BL touch. But first I would like to understand in RRF how to set my Manual Zheight and save those peramiters. My other printer ruinning Marlin, is super fine tuned.

i will be integrating the BL touch next.

I really like RRF.

-

@westech said in Beginner issue: storing Z-offset:

But first I would like to understand in RRF how to set my Manual Zheight and save those peramiters.

There are two ways as has been mentioned above.

When the endstop switch is contacted during a homing move (G1 H1 Z) the Z position is set to the M208 Z minima value. This homing move is part of homeall.g or homez.g.

Now you can fine tune the Z position of the trigger such that Z0 equals the nozzle touching the bed by either adjusting the M208 minima in config.g, or using a G92 Z in the homing file to override the current position.

There is no "live Z tuning" per se. Just edit the file with the correct value.

-

@phaedrux Thanks, I think I got it.

What didn't work:

homeall.g

G92 Z-1.4 ; set Z position to axis minimum (you may want to adjust this)

If I changed G92 Z1.4 as a positive number it would respect that in the console. Displaying Z1.4

But I needed a negative number. G92 Z-1.4 was not respected. and would show it as Z0 in the console.

What worked was adding:

G1 Z1.4 F100

G92 Z0 ; set Z position to axis minimum (you may want to adjust this)

I am printing now and by triggering the endstop then Raising the Z Then G92 Z0. worked.

I really like how RRF can be adjusted so easily. I'm not going to miss going into Platform.io and recompiling Marlin everytime I have change a little thing.

Next stop the BL touch. But I know now how to adjust the Z for different bed heights.

Thanks.

-

@westech said in Beginner issue: storing Z-offset:

But I needed a negative number. G92 Z-1.4 was not respected. and would show it as Z0 in the console.

Why do you think you need a negative number? That would mean your nozzle is 1.4mm inside your bed. That makes no sense. If you're outside of the bed area and can safely move the nozzle below the bed plain, then you should change the M208 Z minima to allow that negative position.

-

@phaedrux Thank you, I haven't worked with the M208, so I will look into that. I'm going to start integrating the BL touch in the process, as I switch bed surfaces.

All I need to do is add G29 after G28 in my start G-code from my slicer?

When I execute G29, it takes forever, must be 5x5. Where do I set it to just do 4 corners and center, or 3x3?

Thanks.

-

@westech said in Beginner issue: storing Z-offset:

@phaedrux Thank you, I haven't worked with the M208, so I will look into that. I'm going to start integrating the BL touch in the process, as I switch bed surfaces.

All I need to do is add G29 after G28 in my start G-code from my slicer?

When I execute G29, it takes forever, must be 5x5. Where do I set it to just do 4 corners and center, or 3x3?

Thanks.

To cope with different bed heights you only need to set the Z=0 datum which involves moving the probe to some fixed location - I use the center of the bed - and issuing a G30.

If the probe is configured correctly then the process will insure the Z=0 has the nozzle just touching the bed regardless of which bed you are using.

Using mesh compensation (which is what G29 is for) is going to be a bit more difficult. Either you live with the time it takes to to create a proper height map (400 points - 20 x 20) or you create a height map for each bed surface and load the appropriate one based on the bed in use.

To use an existing height map in that way you are counting on the consistency in your bed surfaces.

With v3 firmware it is easy to establish a global variable the determines which height map is loaded. The value of the local variable would need to be set each time you changed to a different bed surface.

There is no real point in doing a 4 point or 9 point height map - other than to help cope with an out-of-level bed. It certainly won't hope with minor bed irregularities.

Frederick

-

@fcwilt Good info. On my Marlin Ender 3 with a mirror. It is perfectly trammed and I haven't had to do any adjusting. Even though it also has a BL Touch, I don't usually use it because I get such consistent prints.

I print mainly small prototype parts I design in Fusion, so I don't usually use the whole bed.

i mainly got the Textured PEI bed for making nice face surfaces for project enclosures. The steel plate (Energetic) is far from being as flat as my Mirror.

I will look into the G30. I have the RRF G-code "dictionary" always open on my screen:-)

Thank you!

-

-

@phaedrux Thanks for all your help!

-

he mechanical endstop I don't want to move. If I moved it up, then physically I could never reach the bed