I want to use 3 Extruders

-

@uneumann36 You asked the question "What have I done wrong?" How can anyone answer that when you won't tell us what you have done? I say again, post your configuration file, then we can see.

-

Hey all good!

I want to say thank you , all this information bring me forward.

ANd i will post my config when i am home -

Hey Guys

I am back home and play with my printer and extruder.Of course i am playing in the moment. I will try to heat up the hotend, und make hand extrusion via DWC from extruder 1 and after this extruder 2.

So i make a new config via config tool and bring it to printer.

Now i see 2 Tools , and Bed.

If i switch on tool on, both goes on. and also off when i switch on off.How to test both extruders via DWC ?

Here my config , hope someone has an idea. :

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu May 06 2021 17:04:43 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"ENDER 5 Duet" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1200 Y1200 Z1200 E1500:1500 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X220 Y220 Z300 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H1 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

-

Hi Guys

At least i get my THC-01 working.

But i am not really happy how it works.Also i do not know how to slice a object.

May somebody has experiance with this hot end.

And a question from my side:

Is it possible to change the extruder while printing with no fail?

So that extruder 0 pull back filament 30mm and extruder 1 push filament 30mm and continue printing?

How can this work?Regards

Uwe -

@uneumann36 Yes you can do it, but you need to set a few things up. FYI I don't have a hotend like yours, but I do use a multi-tool printer (E3D chimera) - will try and make it relevant for yours.

Step 1 - you need to define the tool change macros that get executed when you switch between Tool 0 & Tool 1. You'll find information on these here:

https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareCartesianPrinter#Section_Tool_change_filesYou can set up most of this in the slicer, but I find it more intuitive to put in the printer itself.

I think in tfree0.g & tfree1.g you'll add the retract 30mm (though the amazon product description I read says 45mm!). e.g.

G1 E-30 F300 ; retract 30mm @ 300mm/minI think in tpre0.g & tpre1.g you could put the movement command as the docs suggest, or leave blank

Then in tpost0.g & tpost1.g, you would de-retract the 30mm (or 45mm!). e.g.

G1 E30 F300 ; deretract 30mm @ 300mm/minIn your slicer (I use PrusaSlicer), you will need to setup your printer as a multi-tool (or multi-extruder) printer. That then should open up the settings you need.

In PrusaSlicer, you can import a pair of STLs (one for either tool) and it will allow you to select the tool for either one. It will then put the 'T0' and 'T1' commands in the correct places to switch tool through the print.

You will want to play around with a few of the settings in your slicer (e.g. maybe using a prime tower). You may also need to tweak the tool change macros a bit (e.g. faster/slower retract/unretract, change the distance etc).

It can all be a bit complicated and will take quite a bit of tuning to get it right, but you'll get there

-

@engikeneer

Thank your very much for your feedback.Unfortunatly i have not big experiance in programing stuff.

Let me say, in the moment i just can swim a bit.Could you explain me how to do this, what is the exact code for this, and how and where to put it in?

I am sorry for my stupid question.

-

Or any other guy can help me?

-

I try different things, so i am to stupid to adjust this.

-

-

What part of @engikeneer's excellent reply are you getting stuck on?

You can't expect strangers on the internet to create a perfectly working configuration for your printer. Even if we wanted to, we don't know exactly what you have. You'll need to read and research and learn as you go. We can answer specific questions, but you'll have to give us something to work with.

-

@phaedrux

First, i am very sorry for my last comment.

Because i am frustrated why i can´t get this working.

But the explanation of you and your colleagues are super perfect.

Maybe i am to stupid.Maybe i understand this wrong!

I would keep my triple working in two steps.

First, change filament with DWC myself while printing.

If this is working , i can try to do it inside of the slicer.For my better understanding :

It is possible to change the filament while printing?

For example : I print a part that is normal sliced , and with DWC i change the Extruder by hand. And the software pull back the filament automatically the stored length , and the requested Extruder start and extruded the stored length and then continue printing ???? -

@uneumann36 said in I want to use 3 Extruders:

It is possible to change the filament while printing?

For example : I print a part that is normal sliced , and with DWC i change the Extruder by hand. And the software pull back the filament automatically the stored length , and the requested Extruder start and extruded the stored length and then continue printing ????Yes you can change filament during a print. There is even a specific gcode to allow filament changes during a print. M600. Some slicers like prusa slicer allow you to add the M600 at certain layers to do the filament change. But this is a manual process and only really good for changing a color at a layer. This is why printers with multiple tools exist.

In order to use multiple tools you need to define the tools in your slicer and then assign the tools to different parts of the print.

https://www.youtube.com/watch?v=QEYQesc8X2A

This video shows the manual swap process in prusa slicer.This page shows some details on setting up multiple extruders in slicer, which should be pretty similar in prusa slicer still.

https://manual.slic3r.org/expert-mode/multiple-extruders

And maybe a video showing how it's done in a few other slicers as well: https://www.youtube.com/watch?v=xRtvbICRh1w&t=1s

-

@phaedrux

Thank you for your excellent reply.There is one more question from me.

So you know i adjust everything like information i had.

So i have 2 tools.

Work it like :

While printing i switch the tool (from one Extruder to other) via DWC,

and automatically the Extruder who is printing pull back filament like adjusted , other Extruder extrude the length like adjusted and continue printing? -

@uneumann36 said in I want to use 3 Extruders:

While printing i switch the tool (from one Extruder to other) via DWC,

and automatically the Extruder who is printing pull back filament like adjusted , other Extruder extrude the length like adjusted and continue printing?Yes, if you set up the tool change macro files to do the retraction and repriming.

-

So do i understand right,

i have to fill the folders

and then it is working? -

I mean the tfree , tpre , tpost folders

-

Yes you'll likely want to have some commands in there to suit your needs. Think about the tool change process in a very step by step way. What needs to happen to the tool position and filament position on each change? You can use gcode commands in those files to make it do what you want. It can be very minimal.

-

Hi Guys

First , yes i get it working !!!!

THANK YOU VERY MUCH FOR ALL OF YOUR HELP , and your patience with me

My problem was, i did not understand for what exactly is tpre , tpre , tpost for.

May you can make a short explanation in the document for what this file does.Because i am not very good in programming.

Please Note, this should not be nagging.So i am very happy that i keep this working, so the next big steps are waiting for me !

This gives me another question :

I am searching for a Slicer who i can easiely can adjust at Layer number 10 swop the extruder, and for exaple at Layer 20 again and so on. (Without stop / break )I know i can so this in Cura, but complicate like mark position on the part , and adjust .....

Do somebody know how to do ?

Again Thank you.

-

@uneumann36 Glad to hear you got it working

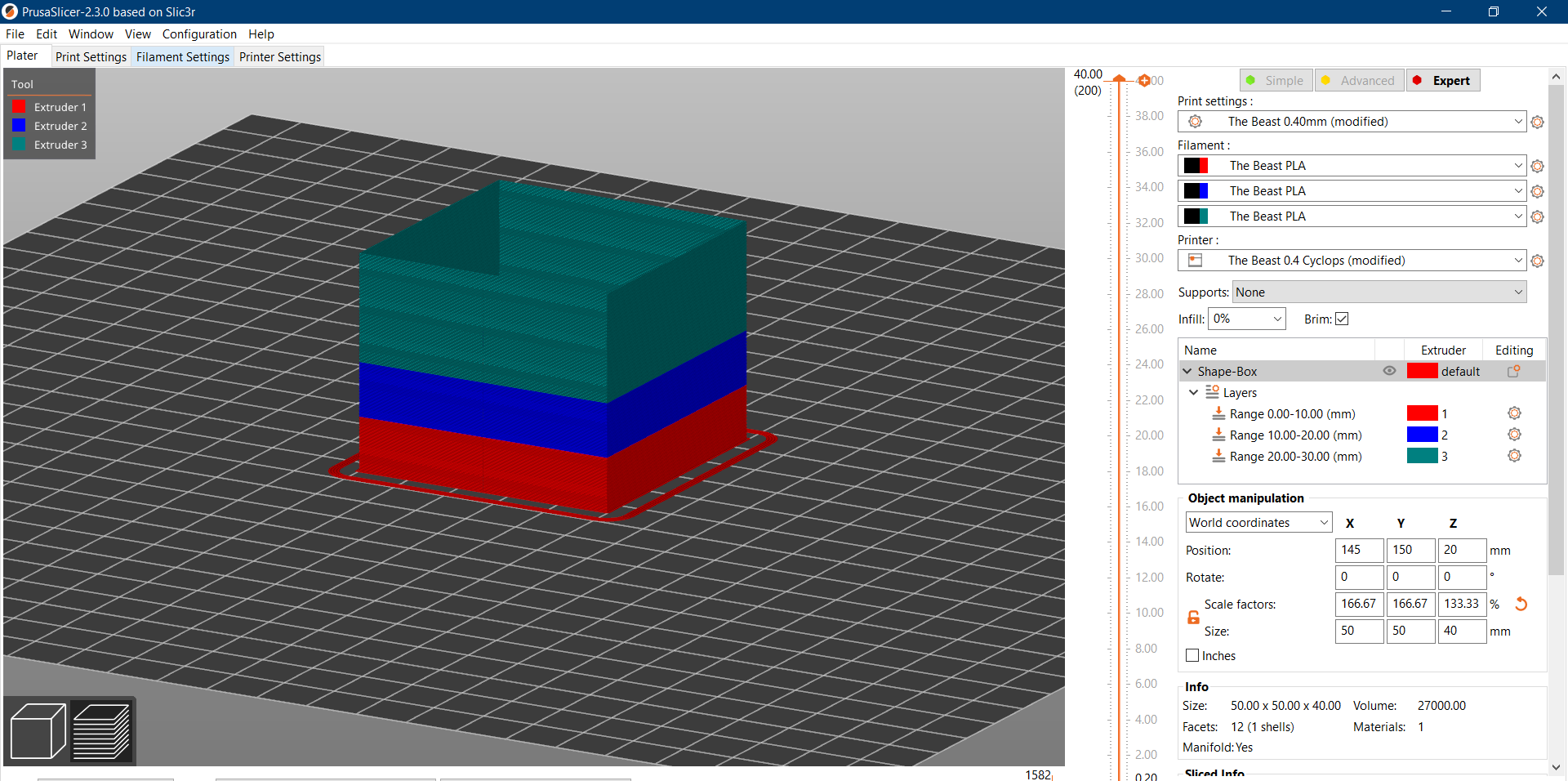

I've only ever really used Prusaslicer (so can't say if it's better/easier than Cura), but it does have an easy way to change tools as you go up the model. You just add a 'Heightrange Modifier', for each band you want, and tell it which Extruder/Tool you want to use for that band (you have to set up multiple Extruders under the 'Printer Settings' tab first, but that is easy).

Here's an example:

There's also a way you can split out part of an object (e.g. just a corner), but I've not worked out how to do that myself

-

@engikeneer said in I want to use 3 Extruders:

Prusaslicer

Sounds good

So can i use the "Prusaslicer" also for an not Prusa printer?