Smart Effector including toolboard-capabilities?

-

@dc42 yeah I to had a longish M3 bolt and nut left over on all 3 of mine but they all did fit together nicely

doug

-

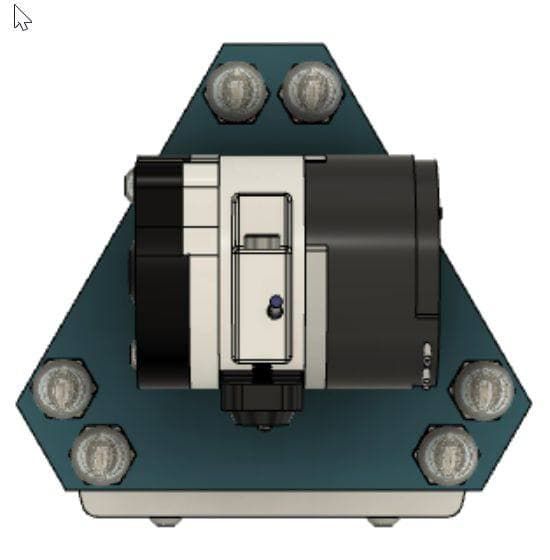

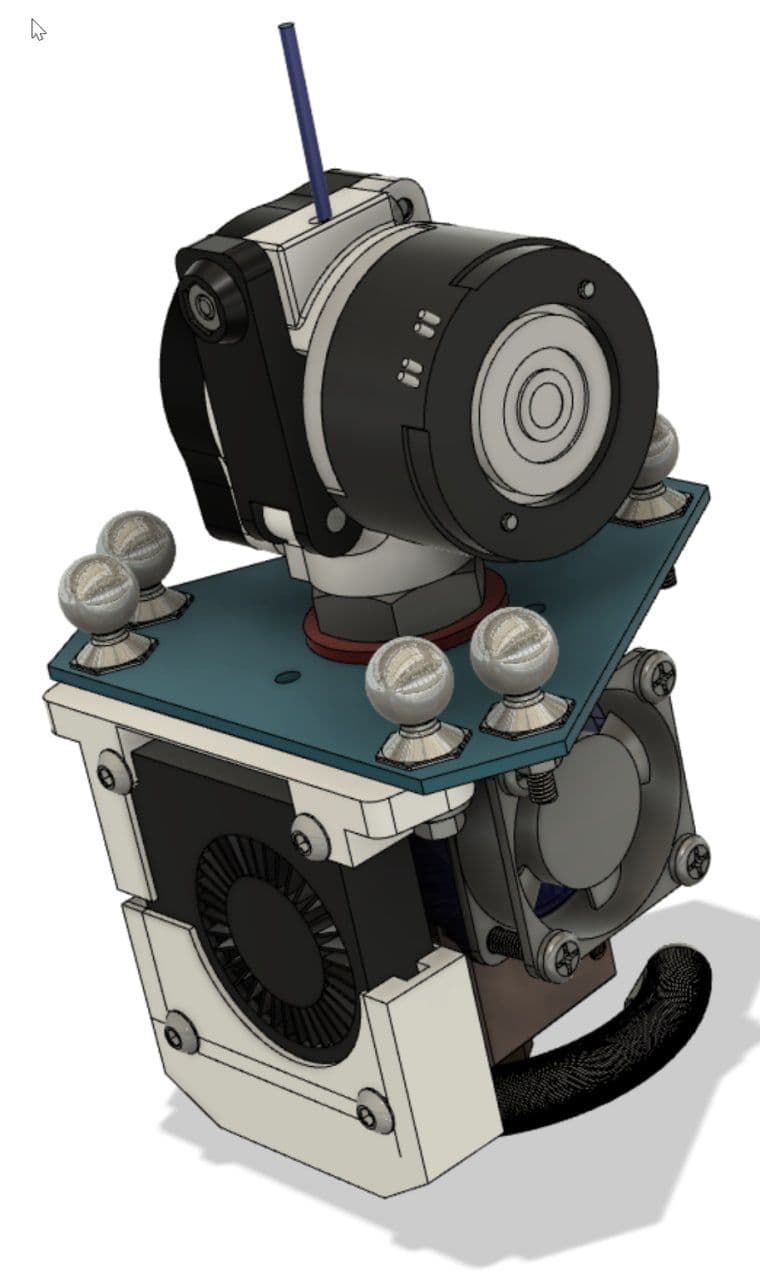

It's clear to me that the Orbiter could not be used with a Smart Effector made to the current dimensions. We would need to increase the rod spacing to at least 80mm in order to accommodate the various parts of the extruder. We are looking into this, however it would make it unsuitable for the smaller delta printers.

-

-

Interesting! However, that reduces the printable height somewhat. What is the printable area of your delta, and how much would you lose if the rod spacing was increased to 80mm?

-

@dc42 said in Smart Effector including toolboard-capabilities?:

Interesting! However, that reduces the printable height somewhat. What is the printable area of your delta, and how much would you lose if the rod spacing was increased to 80mm?

Personaly David I don't think I would lose any build volume at all my bed is 360 Diam I may lose a little bit of Z but not a lot (Our printers are pretty similar apart from mine is a bit wider and upside down and 450 long arms.

So if you want to try it at this size I can easily test one. as I did the first one.

Doug

-

@dc42 said in Smart Effector including toolboard-capabilities?:

Interesting! However, that reduces the printable height somewhat. What is the printable area of your delta, and how much would you lose if the rod spacing was increased to 80mm?

I lost 45mm in print height, and coincidentally without even thinking about it or trying, my print height now exactly matches the print area of 320mm as I was slightly longer on my vertical rails anyway.

-

@dc42 found this too

-

This topic is interesting!

Ordered an Orbiter too. I'll want to use it in my Frankenstein Predator.

Please keep us updated about possible Smart Effector updates - looking forward to this

-

We do plan to produce a combined Smart Effector and tool board, however we need to get another hardware project completed first.

-

@dc42 said in Smart Effector including toolboard-capabilities?:

It's clear to me that the Orbiter could not be used with a Smart Effector made to the current dimensions. We would need to increase the rod spacing to at least 80mm in order to accommodate the various parts of the extruder. We are looking into this, however it would make it unsuitable for the smaller delta printers.

Hi dc42,

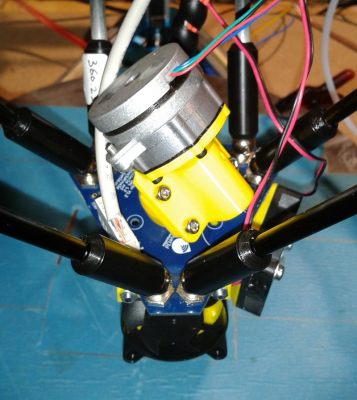

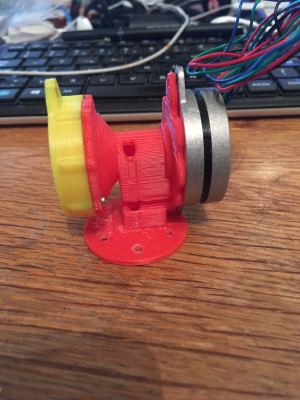

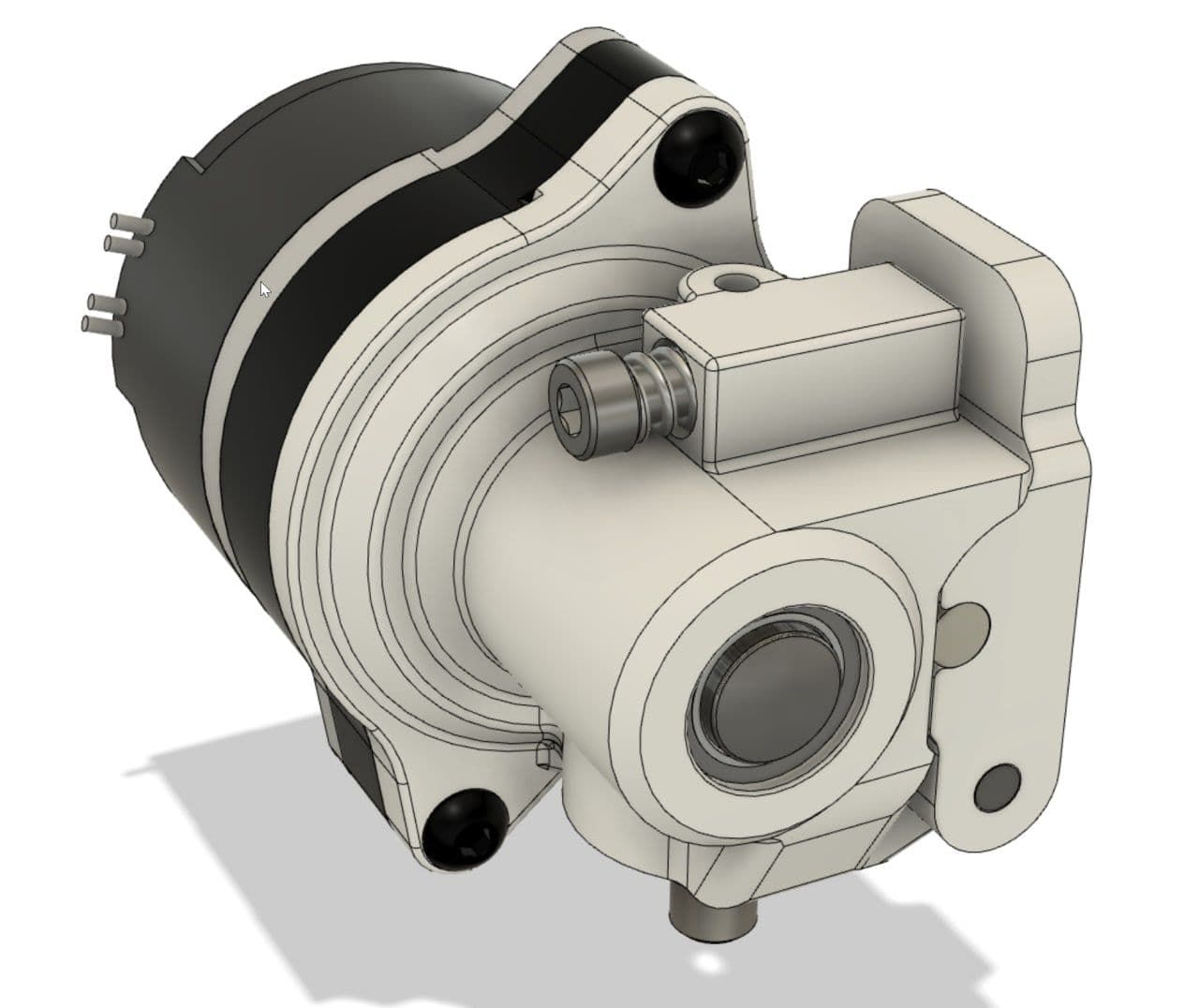

I just stumbled across this thread and wanted to guide you back to 2016 , when we discussed the cycloidal direct drive. (I still have it laying around)

I've made an 45 degree adapter for it, that suited the smart effector pretty well.

Another way to mount it, was the split motor/gearbox idea.

I could try to reuse my motor and design a BMG-drive for the Smart effector?

-

video_2021-02-11_00-13-44(1).mp4

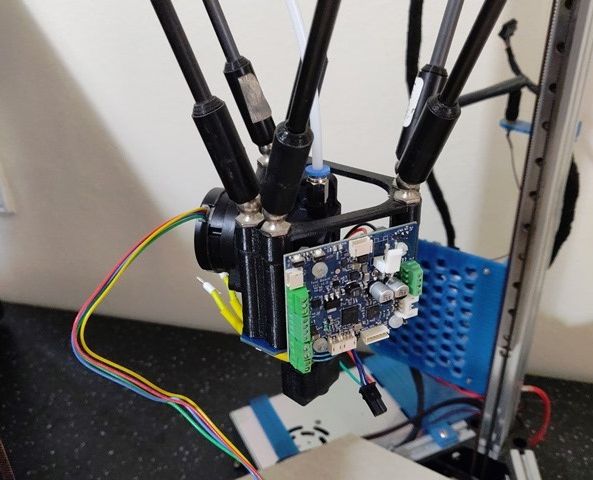

We are doing some prototyping, with a regular orbiter, changing some aspects of the body.It actually is a pivot extruder, so it can rotare freely within the rod arms...

It´s not my doing, just a friend´s I am helping him to achive it

-

Looks good!

We do have plans to produce a combined Smart Effector and tool board. The main decision we need to take is how large to make it.

-

@dc42 We are just two 3d printing fans....just doing it as a hobbie...no bussiness attached

-

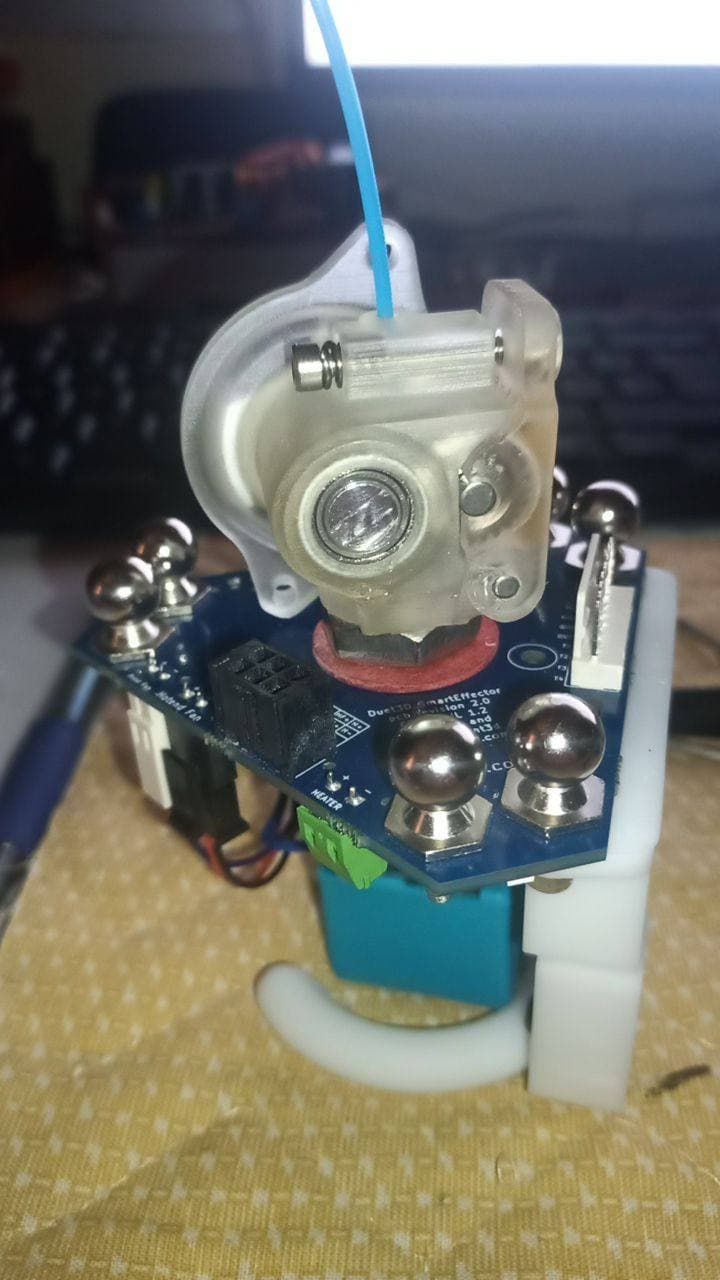

@dc42 Hi, I'm the designer of the Orbiter extruder.

For delta printers you need the version with flipped gears like this one:

https://www.thingiverse.com/thing:4609940The filament path is closer to the middle of the extruder so has a better clearance towards the rods.

I designed an adapter to fit this version you can find it here:

https://www.thingiverse.com/thing:4648938The result is not the best but it works.

The upcoming V2 will be more optimized in size and would fit better to delta printers. But I have not tried it yet.

-

@Lorincz-Robert , thanks. Looking forward to the V2!

-

here is a teaser video of V2:

https://www.youtube.com/watch?v=hpvJZ1BHheM&t=2s -

@Lorincz-Robert said in Smart Effector including toolboard-capabilities?:

here is a teaser video of V2:

https://www.youtube.com/watch?v=hpvJZ1BHheM&t=2sWatching the video in the context of this thread (which is specific to the smart effector and delta printers), my impression is that the filament path doesn't seem any closer to the center of the extruder (compared to the "CR" version of the orbiter.) If the offset is the nearly the same, the same type of adapter that moves the extruder high up above the effector will have to be used... At that point, many people will prefer a full size "flying" extruder floating 40 to 50mm over the effector.

I'm also concerned about the low suggested 'jerk' suggested for the orbiter. Low jerk negatively impacts pressure advance, and more pressure advance would be needed when there's a long filament path between the extruder and effector.

-

@apak this looks very promising, is there any way to follow your progress on this project? like a thingiverse page or a forum thread?

-

@Hergonoway It´s not my doing...I am just a part of it as I "consultant". The guy doing it might do some tweaks, but He is planning on a whole differnt design for a direct extrusion for smarteffector. He is up to date with this thread so He might post something

-

We'll hold fire on designing a combined Tool Board/Smart Effector until we know what rod spacing we need to use to accommodate an extruder mounted directly on it. I think it will be around 80mm, but we really need to know extruder dimensions to be sure.