if you use simplify3D try to add a wipe movement of 1mm for start and check "retract during wipe movement" you should get improvment on stiching between layer. If blobs appears elsewhere (corner for exemple) you'll need to tweak up jerk and acceleration and eventually use pressure advance settings if you've got bowden over 30cm.

Best posts made by Hergonoway

-

RE: Oddblobbs :) Looking for some assist to settingsposted in Tuning and tweaking

-

RE: Fans vs Berd-Airposted in Smart effector for delta printers

@kerzal said in Fans vs Berd-Air:

What I wonder is if the two designs listed below + 2x 40mm fans will work on the smart effector, or if it will generate too much weight and interrupt the auto-calibration?

No problemo. No enough weight to "wobble" the hotend to the point it'll engage false triggering. Even if it happens you can fine tune the trigger sensitivity of the smart effector.

-

Cancel part of a print (that legendary feature)posted in Duet Web Control wishlist

Hi,

Just heard of this plugin for octoprint (Thanks "CNC Kitchen" on Youtube), this is really the kind of feature that should be implemented in Firmware+DWC

https://plugins.octoprint.org/plugins/cancelobject/

"This plugin allows the user cancel single objects (or groups of objects) during a print while allowing the remaining objects to print normally. Currently, this functionality is limited to gcode sliced with Simplify3D using a unique process for each object (or group of objects). Regular expression settings will allow this to be used with other slicers if/when they include object-specific comments in gcode."

-

RE: Oddblobbs :) Looking for some assist to settingsposted in Tuning and tweaking

Note that using G10/11 won't handle "wipe during retraction" option in S3D.

I'll suggest you to use this model : https://www.thingiverse.com/thing:909901

Add it X times in S3d and customize each process with different retraction settings. (Don't forget to print with piece by piece option with enough clearance) the model is small it'll be easy.

At least you'll end up with a clean base to fine tune reactions with more complex models.

-

RE: Working with 24v but having a noctua as heatsink fan in 12vposted in Smart effector for delta printers

@jacotheron & @t3p3tony thanks for your replies, I'll keep up with a DCDC step down at the Duet side then, I've got a bunch of these littles guys :

-

RE: 24V Pump - can I connect direct?posted in Duet Hardware and wiring

255K is way to high try 25K (F25000). In my case the sound and the temp dropped a lot.

Note that I've directly connected the 1/8" ID Tygon tube to the metal tube, it reduce pressured area and reduce heat from the pump mechanism (the white plastic part)

-

RE: Berd-Air pump configuration notes for Duet usersposted in Tuning and tweaking

Standard tubing used by berdair are 3/32" OD aluminium tube.

I've personnaly switch to soft brass tube of 1/8" OD (Wall: .014") from K&S. Used a wire in the tube to bend it (honestly it's almost mandatory for larger tube) and solder the end instead of pinched it.

I don't recommend stainless tube if you want to make a tube ring with 12mm ID, because it already not so easy with softer material.

If you go over 3/32" it "may" require makerbot type nozzle which has 8mm clearance compare to 5mm clearance from E3D nozzle type, mostly for convenience especially if you use a headblock sock.

-

RE: 40mm cooling fan duct for Smart Effector - thoughts?posted in Smart effector for delta printers

@chipsa82 I'll post it on thingiverse in few days, need to rework some clearance for that damn screw under the fan duct

First prototype print works like a charm

-

RE: My Deltaposted in My Duet controlled machine

@craig yeah welcome to the MotorOnTop club >high five<

-

RE: RBGW Led + Duet Wifi (PWM pin or alternative board)posted in Duet Hardware and wiring

Almost

sorry for my awfully dense explanation (I'm French)

sorry for my awfully dense explanation (I'm French)White led draw 60mA on 1/6 of a meter (on a strip of 10 led out of 60) so we can say 360mA per meter and as you understood each color draw 1/3 of that so 120mA per color per meter.

So I'll stick with my initial choice with your recommendation about resistor. I'll post a picture once done

Thanks again!

Latest posts made by Hergonoway

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

@mrac1 could you share a step/F3z file of your double blower mod for the mosquito I definitely need to try that, it looks awesome, but I can't find it on your thingiverse page...

I assume that you've got a 713maker mount too.

I assume that you've got a 713maker mount too.I thought it was in the D3E step file, but I can't find it in either.

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

@o_lampe said in Smart Effector including toolboard-capabilities?:

@hergonoway

I have to read up on ASA or PCmax filaments as alternative for ABS (I'm done with that) Do they need a heated chamber?For ASA, no need. For PCmax, if you've got a chamber, I'd say it's better to use it especially if you target big printed pieces, but it's not mandatory. PC tend to build internal stress while being 3D printed. But you can anneal PCmax easily after print since glass temp is high, I usually anneal my pieces between 1h30 and 2 hour in the oven and let it temper as the oven cool down.

I personnaly don't have an heated chamber and print both without issue.

Also my advice for 2021 is to simply abandon ABS, it never has been a good material filament for FDM, just let it go. ASA is a far better alternative.

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

@o_lampe yeah heat concerns me a bit, but I generally print mechanical parts in ASA or PCmax, so it "should" be ok, I still have to print my version of the D3D tho to see it for myself. Regarding retraction speed, it implies going from 50:10 to 50:8 so there's no impact since we're dealing in the <1mm field. I could be slightly concerned for jerk but I need to test it beforehand.

That's remind me that V1 of HextrudORT should be available

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

@o_lampe said in Smart Effector including toolboard-capabilities?:

BTW: I found a cheaper/stronger motor for Orbiter and Sherpa mini. It's 2mm longer than the LDO. Will it still fit for the SmartEffector?

there's a very recent alternative if you want more torque : http://ez3dpstore.com/PRE-ORDER-Sherpa-Mini--NEMA14--8t-Pinion-Motor_p_69.html

8t instead of 10t, still in pre-order state tho, but worth the wait imo

-

RE: Fans vs Berd-Airposted in Smart effector for delta printers

@lord-binky don't use salt, use electric wire. Put it in the tube, bend it and pull the wire. For example, iirc, K&S soft brass (something like 8121) tube is a perfect match for heater cartridge electric wire gauge.

Edit: yes heater cartridge cable perfect fit 8121 K&S soft brass tube

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

I'm currently dealing with the same issue regarding the filament path right after the BMG gears in my version (the path before the BMG gears is not as critical, I'll keep it as it is). I think that maybe using a PTFE tube correctly cut to follow the curve of the gear is not a bad idea too. I'll try this approach and gonna design a cutting jig to perfect cut the required PTFE part.

Also Titan Extruder got this kind of piece already designed, maybe it could fit, and it would cost nothing on aliexpress.

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

So I found 2 other projects very closed from the D3E that I'm going to add to my current fusion360 D3E-WIP in order to eventually find new structural ideas that could be merged or refactor from.

#1: the sherpa mini: https://github.com/Annex-Engineering/Sherpa_Mini-Extruder

#2: HextrudORT (no yet available)

https://www.youtube.com/channel/UCQB3-0PIEN_wn-932h0LNOw

-

RE: M207 accel limitation for z-hopposted in Gcode meta commands

so M201 would define accel and M203 would define speed, so z-hop is basically max out to what Z axis can achieve? and M204 is out of this equation.

-

M207 accel limitation for z-hopposted in Gcode meta commands

Hello,

I assume that in M207 the z-hop acceleration is set and limited by M201 'Z' param, but is it also the case while using M204?

I've got an issue where I'd like to reduce the z-hop acceleration at 4000 max (above it'd "tap" the piece at the end of a z-hop move) while keeping travel accel on the Z axis above that value for non-z-hop travel moves (g28, pause, etc), assuming that I want to keep 6000 in acceleration for travel move in M204, how can I limit the z-hop to 4000? If I limit it with something like 'M201 Z4000' it'd be for the whole z axis even if I put 'M204 T6000' it won't go over 4000, right?

btw I've got a delta, so I live in the world where X/Y/Z is abstract.

-

RE: Smart Effector including toolboard-capabilities?posted in Smart effector for delta printers

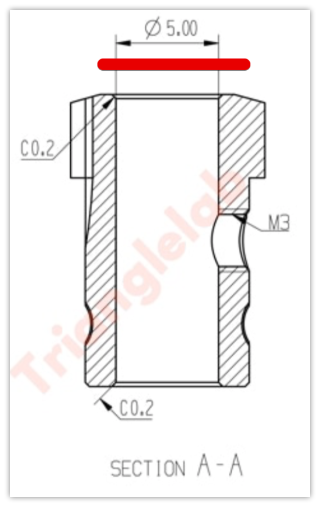

it's got the 5mm ID drivegear:

where the only drivegear alternative trianglelabs proposes (the 8mm) got this fatty look and doesn't have the same barrel bearings. The 8mm kit pic:

VS The ones in the kit:

VS The ones in the kit: