Enclosed chamber temperature monitoring

-

Thanks for the reply.

Your heated chamber looks amazing.How well does it work?

Would you be willing to share your heater and fan spec's?

I assume that the walls are Polycarbonate or Acrylic. Is this correct?

Does the heater block get hot enough to warp or melt the plastic walls? -

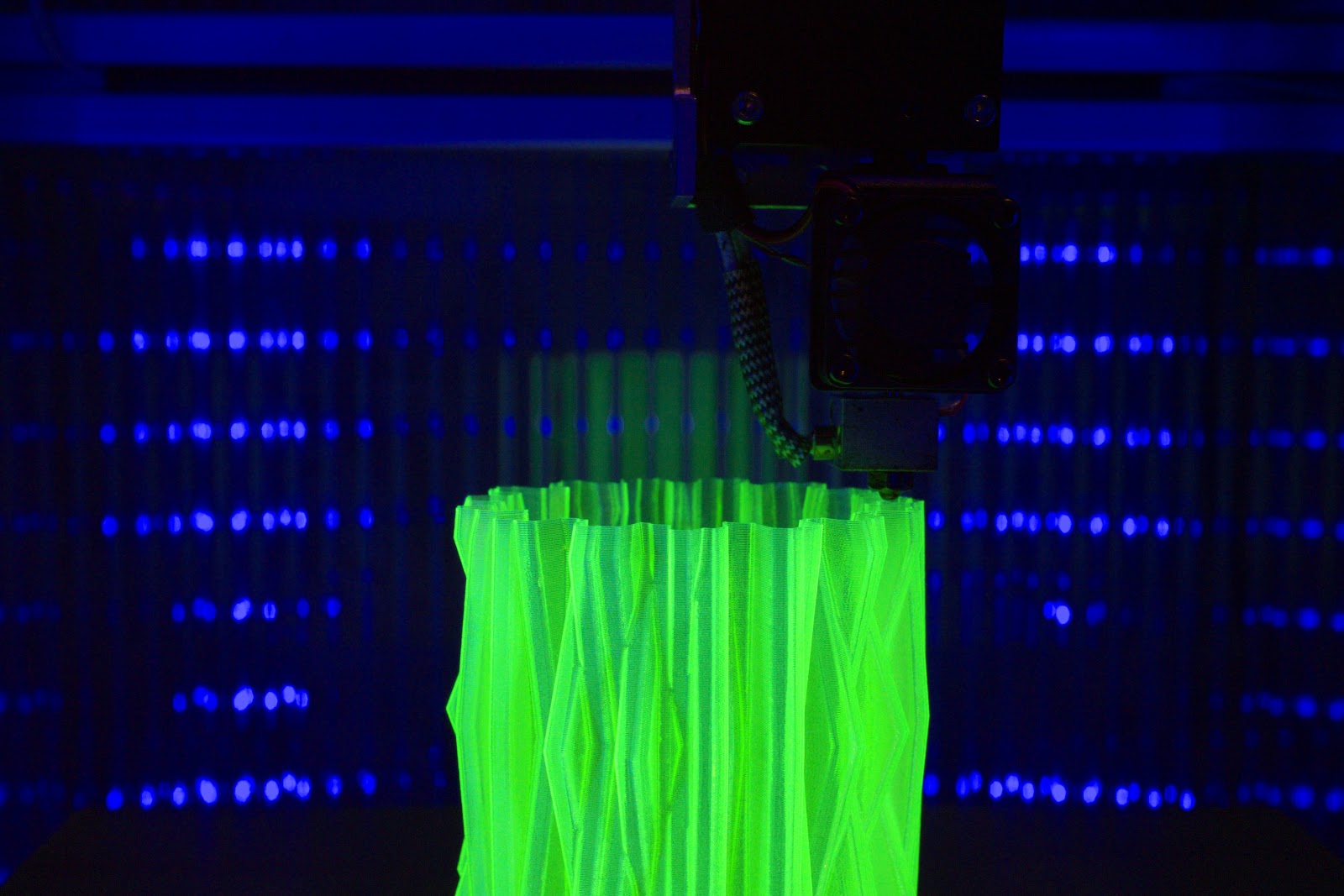

The heater is a 500W line powered unit that came out of an old Stratasys printer. You can see the SSR that switches power to it on the left side in the first photo. The fan is connected to the input of the SSR, so when the heater is on, the fan is on. The enclosure volume is about 420 liters and it takes about 20 minutes for the chamber to get to 50C when the bed heater is set to 100C for printing ABS. I had to limit the chamber heater power to 500W because the bed heater is a 750W unit and between the two I am pushing the limits of what you can do on a single 117VAC circuit.

The fan is an industrial 24VDC unit that is specced to operate above 50C. FCI DA-119B-W24.

The enclosure walls are dual layer polycarbonate which is super tough, lets light through, and provides thermal insulation. It also provides some nice effects when the LED bars (white and UV) are reflected in the PC. The material is commonly used to make green houses. It's 8mm thick and fits into the slots in the 4040 t-slot frame. It works well, and looks pretty nice, but that sort of assembly can make some repair/modifications to the printer difficult because I have to partially disassemble the frame to remove the PC panels. Fortunately, most of the mods happen at the extruder carriage and the Z axis, neither of which requires any frame disassembly.

I added a bent sheet metal heat shield so the chamber heater fan doesn't blow against the Z axis motor. Without the fan the heater gets blazing hot, but with the fan, plastic debris that falls off the bed plate and lands on the heater doesn't even melt. The heater doesn't do anything to the PC walls.

I still need to add a shield, probably a piece of rolled perforated sheet metal or screen, to cover the heater and electrical connections. Once I have a suitable piece of material I'll add a TCO to kill the heater if the fan or SSR fail.

-

I have a similar setup to TDD to heat the inside of my printer's chamber. I use an old e3d hotend thermistor (the one with the blue leads) which I installed at the top of the chamber (my reasoning was that the chamber should reach the set temperature up there first). To heat things up, I use a 230V powered 1700W heater accompanied by its matching hot air fan which are both hot oven spare parts. The heater should be set up similiarly to Marks as well. It's limited to 70% duty cycle atm iirc and reaches 180°C in about 45-60 min.

-

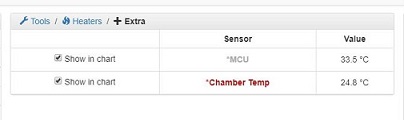

I also just use a generic 100k thermistor without a heater ascociated, it shows up on the "extra" tab and can be graphed.

M305 S"Chamber temp" P103 T100000 B3988 C0 R2200 X1 ; Case temp 100k semtek on E0 thermistor input.

-

Summarising the above, there are two ways:

- If you want to control the chamber temperature using a heater and thermistor, configure it using M141 and it will show up in DWC as normal (but not yet in PanelDue).

- If you don't want to control a heater but you just want to display the chamber temperature, create a named virtual heater as in the post by @bearer.

-

@bearer

Thanks for the help.

I purchased a generic 100k 3950 Thermistor and installed it.

It works just as you described, however the temperature reading appears to be off by about 20°C.I used the code "M305 S"Chamber temp" P103 T100000 B3988 C0 R2200 X1".

Is there a section of the code that I need to change based on my specific thermistor, or do I need to somehow tune the thermistor in order to produce an accurate reading? -

I have a Maestro board and it uses a different series resistor so the R2200 value may be wrong if you have a Ethernet or Wifi Duet.

The B3988 part allows you to adjust the response as well.

I found these links helpfull when trying to get mine to show the correct temperature.

https://www.ametherm.com/thermistor/ntc-thermistor-beta

https://www.thinksrs.com/downloads/programs/therm calc/ntccalibrator/ntccalculator.htmlAs well as the wiki for the M305 command

https://duet3d.dozuki.com/Wiki/Gcode#Section_M305_Set_temperature_sensor_parameters -

@vacalos said in Enclosed chamber temperature monitoring:

@bearer

Thanks for the help.

I purchased a generic 100k 3950 Thermistor and installed it.

It works just as you described, however the temperature reading appears to be off by about 20°C.I used the code "M305 S"Chamber temp" P103 T100000 B3988 C0 R2200 X1".

Is there a section of the code that I need to change based on my specific thermistor, or do I need to somehow tune the thermistor in order to produce an accurate reading?As @vacalos says, R2200 is wrong for the Duet WiFi. You can leave out the R parameter from the M305 command, then it will use the default value.

-

Thanks,

It's working perfectly.

I also tried using the "B" & "R" values that are used for my Heated Bed thermistor and they appeared to work as well.M305 S"Chamber Temp" P103 T100000 B3950 C0 R4700 X1

-

Is there a way to get the temperature values that appear in the "Extra" tab in DWC to appear along with the Heaters on the "Tool" tab?

-

Trying to get the Chamber Temperature as shown above

M305 S"Chamber temp" P5 T100000 B3988 C0 X1 ; Case temp on E4 thermistor input.

I left out the R because we are running the Duet2 wifi. We are running the Duet2 wifi and Duex 5 and i'm connected to E4 thermistor 5 on the Duex 5

I'm not showing the Chamber heat in the +Extras as shown above?

Any help would be much appreciated -

@Sculpt-Fabricator Please start a new thread with your details. Include your firmware and DWC version as well.

-

@sonderzug Are you using a water-cooled extruder?