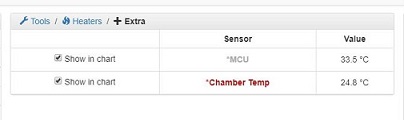

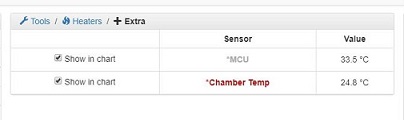

Is there a way to get the temperature values that appear in the "Extra" tab in DWC to appear along with the Heaters on the "Tool" tab?

Is there a way to get the temperature values that appear in the "Extra" tab in DWC to appear along with the Heaters on the "Tool" tab?

I suspect the crimped PT100 connections may cause an intermittently poor electrical connection which results in Heater Faults.

I was wondering if anyone has soldered the PT100 sensor wires to the smart effector.

If so, how did you get to the pins underneath the molex style connector on the effector?

Hello,

I am aware that this topic is a little old, however I am attempting to get a Y-Splitter to work on my Delta printer and I'm having some problems. I was hoping that someone that has successfully accomplished this task could offer some advice.

So far I have I printed and installed the Y-Splitter from the Prometheus website and installed the special longer heatbreak. I've also wrote the TFree, TPre & TPost files (initially using the recommended values then using slower values for retraction). I'm experiencing problems when changing filaments. I'm not sure if it's due to:

Does anyone have suggestions or experience resolving s simliar issue?

Can this type of setup be made to work consistently?

I initially used the filament chaning speeds recommended on the prometheus website

I think you are correct.

After watching the printer closely during a print, I can see that the 'stutters" coincide with a change in direction in the X-Y plane. This motion is obviously intentional and probably due to pressure advance as you suggested. I guess I never watched the extruder gears closely enough to have noticed that motion before. Thanks for the advise.

What would you suggest an acceptable Pressure Advance setting is for a bowden tube approximately 500mm long?

On the reprap G-code wiki M574 is the command used to set endstop configuration?

Thanks again for your reply.

I purchased stepper Part # 17HM19-2004S.

2.80 VOC

2.00A

0.90 Step Angle

Do I have an incorrect setting in my config.g's M906?

I purchased both of the motors (old and new) from "StepperOnline".

Both are wired (pined) the same.

Thanks for your reply.

The extruder was working ok before and it is still working ok. It just appears to be stuttering for no reason.

I am attempting to determine if this is caused by incorrect settings or hardware issues.

I'm concerned that the motor may be skipping steps which may lead to under extrusion.

I was hoping the video link I posted would help somebodu isolate the problem.

I changed the extruder motor.

The old motor had a 1.8° step angle and the new motor has a 0.9° step angle.

The old motor was also smaller.

Due to this I also changed the amps in my M906 command fro E800 to E1000 (sorry, I just noticed I entered the old amps in my original post).

Thanks for your reply.

I don't think that the temperature is an issue, as It's set at 220°C for PLA.

I don't think the hotend is jammed because if I extrude 100mm @ 5mm/sec (220°C) in DWC the extruder seems to work smoothly without stuttering.

It actually prints ok.

I have printed several test cubes and retraction tests since I changed the extruder motor.

I noticed the stuttering during a test print and am worried the motor may be skipping steps (but I really don't know).

I am having an issue with my extruder motor.

It appears to be rapidly moving back and forth (or stuttering) for no reason.

Below is a video link showing the stuttering.

https://www.dropbox.com/s/stlf1lglxtwdj8e/Extruder1.mp4?dl=0

The extruder is an e3D Titan.

The motor has a 0.90 step angle.

I believe it may be due to my settings.

Below are the relevant settings.

M906 X1000 Y1000 Z1000 E800 (set motor amps (mA))

M201 X3000 Y3000 Z3000 E1000 (Accelerations (mm/s 2))

M92 E837 (steps/mm)

Any advise would be greatly appreciated.