Non-Linear Extrusion

-

M592 D0 A-0.0593 B0.475

If your extruder behaves anything like mine, then the A value should never need to be negative, and the B value should be much smaller than you have it.

-

Obviously I was plotting the wrong data.

What do I need to plot and find the trend line for?

Perhaps the additional amount needed like so?

-

Last time I ran the correction I calibrated my extruder steps per mm at 1mm/s. That would bring your first value to 0 correction which may effect the results the spreadsheet software gives. It shouldn't in an ideal world as the curve remanis the same, just altering the point at which the y-axis of the graph crosses the plot.

Edit: Sorry missed last post. Yes, you are plotting the additional correction required. So if you need to multiply your current extrusion by 1.2 for a specific speed the the value you'd plot would be 0.2.

-

@alexander-mundy

If you multiply 98,9 * 1,011122346 you get 100, so this is correct.

Also if you look at the formula for M592 1 + min(L, Av + Bv^2), you can see that you get that exactly. -

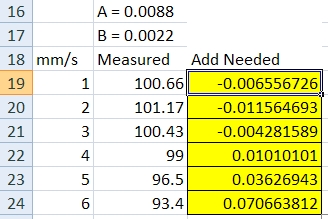

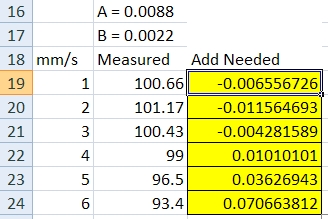

Thanks guys, cleared A & B and corrected my steps/mm to give correct extrusion at 1mm/s and ran the 100mm macro and the trend line gave A=0.0088 and B=0.0022 so I used those values and got the following results

After thinking about this for a bit it made me wonder if the correction should be recursive since you are not actually going to get the corrected amount but the corrected amount minus a % under due to the effect it is correcting? Anyway I don't have more time right now to mess with it but will mull that over.

-

Yes I gree with that. While you have got data points for the right amount of extrusion it is not necessarily at the right speed. Or at least that was the case the way I did it.

I'll check mine next time around but at the moment this needs to be with the head moving so non-linear extrusion is used. Be aware that with these moves the feed rate is soley referring to the motion axis and the extrusion is paced to complete within the move.

Other option is to alter the extrusion amount at each speed amount until you get a target extrusion length and calculate the required correction from that, rather than calculating the correction required to reach the target. Guess this would be more accurate.

-

I made a recursive spreadsheet that sums 6 iterations (yes way overkill, 3 would probably be sufficient) and set A & B back to 0 and started from scratch. The real life results are very good and probably within my measuring tolerance. Since there isn't a "c" in M592 I also had the spreadsheet correct the steps/mm based on the average of the real life results with M592 values in place.

-

@alexander-mundy That's great. Could you share your excel file?

I don't suppose you could post a picture of an actual extrusion pattern before and after the calibration to show the under extrusion at higher speeds and the corrected extrusion afterwards?

-

Edit (Here was the wrong results I removed)

If this works, here is the spreadsheet

-

Actually that was the correct results.

Here is a non recursive

And the real world results from the non recursive

Note that I dropped the 6mm/s from the newest one because I think I might have been getting some lost steps at that speed and I hadn't corrected steps/mm to extrude correctly at 1mm/s

-

undefined Alex.cr referenced this topic

undefined Alex.cr referenced this topic

-

undefined Alex.cr referenced this topic

undefined Alex.cr referenced this topic

-

undefined Alex.cr referenced this topic

undefined Alex.cr referenced this topic

-

undefined Alex.cr referenced this topic

undefined Alex.cr referenced this topic

-

undefined mrmkw referenced this topic

undefined mrmkw referenced this topic

-

undefined mrmkw referenced this topic

undefined mrmkw referenced this topic

-

undefined mrmkw referenced this topic

undefined mrmkw referenced this topic