Duet3D announces new tool board at FormNext

-

@Surgikill not yet, Tony normally does the drawings and STEP models but he is very busy with Formnext follow-up and SMRRF preparation.

-

@Surgikill said in Duet3D announces new tool board at FormNext:

@fcwilt said in Duet3D announces new tool board at FormNext:

@Herve_Smith

You consider the prices to be an issue?

The money I spend on hardware is dwarfed by the money I spend on filament.

Frederick

Toolboards are primarily made for tool changer setups, so multiply your cost difference by the number of toolheads. I'm currently building a tool changer, and each toolhead is going to run me close to $400. At some point, cost becomes a favor. When my toolhead alone is over double the cost of an ender 3 you have to take a step back and reevaluate.

I run RRF-36's on my toolchanger and wish I set it up that way sooner.

-

@edsped those actually look like they might work perfectly. A ton cheaper too.

-

@Surgikill said in Duet3D announces new tool board at FormNext:

@edsped those actually look like they might work perfectly. A ton cheaper too.

No issues on my end so far but I have to admit I'm intrigued by the scanning probe but at more than twice the price for the board not sure if it would be worth it.

-

@Surgikill said in Duet3D announces new tool board at FormNext:

those actually look like they might work perfectly. A ton cheaper too.

But they are a funny shape. Who wants a printer with parts that have a funny shape. Give me a good old rectangle every time.

Frederick

-

@edsped Scanning probe would be good. I guess I could have one toolhead with a scanning probe and a euclid probe, and use either depending on the build surface, then do the rest with a fly-rrf-36.

@fcwilt

Although, I do like that most of the connectors are along the bottom edge, and the stepper is along the top. Connectors along the sides have been a real pain for me designing slim toolheads so I can increase tool capacity.

Although, I do like that most of the connectors are along the bottom edge, and the stepper is along the top. Connectors along the sides have been a real pain for me designing slim toolheads so I can increase tool capacity. -

@fcwilt My Orbiter extruders have the same funny shape at the back thanks to their NEMA14 stepper so I am set. And it is amazing how you can hide the funny boards shape inside an enclosure so the one on the NEMA17 does not need a sheet thrown over it if companies is over.

-

I actually like the shape and as has already been said, having connectors on all 4 sides seems like it would add clutter. For me the RRF-36's are nice and compact. I'll likely grab the step file when it's released and see how it compares though.

-

I was just making a funny remark about the shape.

I assume it is shaped that way to fit something else.

So what is that "something else"?

Thanks.

Frederick

-

@fcwilt the RRF-36 is shaped to mount on the rear of a nema 14

-

@jay_s_uk said in Duet3D announces new tool board at FormNext:

@fcwilt the RRF-36 is shaped to mount on the rear of a nema 14

There must be more to that. A NEMA 14 is square. The RRF-36 is not.

Frederick

-

@fcwilt round nema 14's aren't square... https://www.omc-stepperonline.com/round-nema-14-bipolar-0-9deg-8ncm-11-33oz-in-0-65a-36x20mm-4-wires-14hr08-0654s

they're now also the most popular type of motor to use on an extruder -

-

@fcwilt Let me guess, back in math class you were the one to yell out Pie aint square, pie are round . Right?

-

@KenW

No, not that I recall.

It just seems to me that they made that shape to fit onto/into something else where that particular shape was well suited.

I doubt they picked that shape for artistic reasons.

Frederick

-

@fcwilt Southern humor does not translate well I take it. The complete version of that one is.

Pie aint square. pie are round, cornbread are square. -

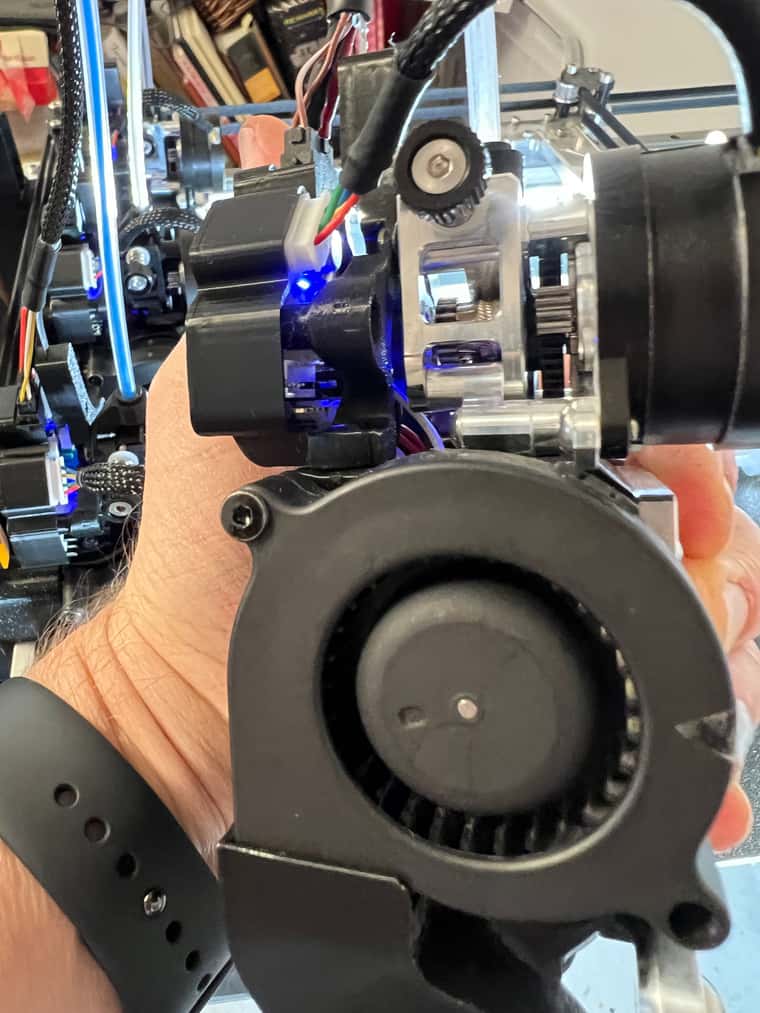

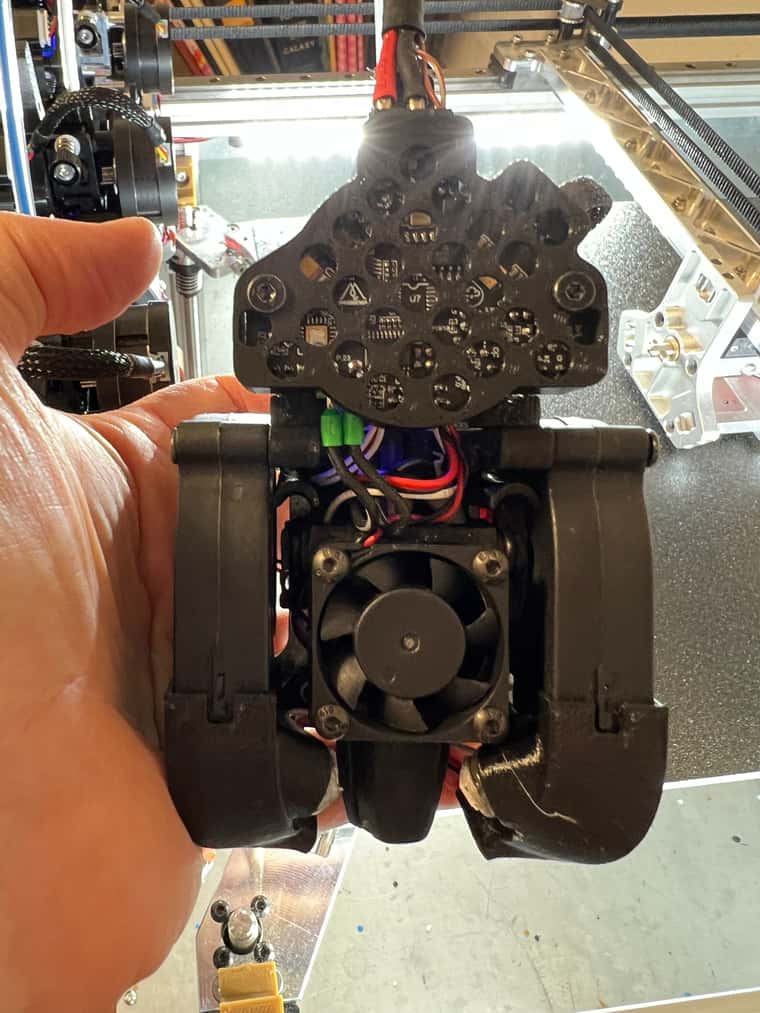

@fcwilt I don't know what the design parameters of the board, but you can guess from these pictures:

It doesn't fit behind the motor, it fits on the side, but it is the same width and height as the motor and extruder. This picture makes it look big, but that's a NEMA 14 round stepper, it really is tiny and light, even compared to a Hemera. Connections are forward and back, rather than up or down, and the mounting is very specific to the Roto extruder (it has the same spaced mounting holes on the other side of the extruder). Connectors are the standard ones E3D fit to their heaters, fans and thermistors, so they just plug straight in. Only the CAN connector exits from the top. There's a hot end fan on the other side, and I don't know where a part fan would fit on. It looks like the board could have been square, but for the top mounting hole. Probably the first Duet board with rounded corners - someone asked at Formnext why we didn't put rounded edges on our boards, and I pointed them towards @T3P3Tony!Ian

-

@droftarts and the CAN connector is the same one that's been adopted by Mellow and BTT (XT30 2+2)

-

Well, looks like the roto is available for purchase through filastruder. Going to wait to purchase until the documentation is available.

-

Eh, I just found some basic documentation and max ambient printing temp is 40C. Think I'm going to have to pass on this extruder.