Duet 3 Scanning Z probe

-

@gtj0 you can use different size coils, you just need to adjust the number of turns to get the inductance to be around 16uH. Larger coils can work at greater distances to the bed, while smaller coils provide greater XY resolution.

The FFC cable can be longer than the one we supply, as long as it is secured so that its capacitance to ground doesn't change as the head moves. However the board should be mounted on the tool head. It's very light.

@zapta we found that when using small coil we were able to detect the magnets under the bed, but not when using the larger coils the we are shipping. Preferably, choose the mesh to avoid the magnets. The sense coil should not be mounted very close to large metal parts on the hot end.

-

@gtj0 On the stand at Formnext we also had a development coil board with a hole through the middle. The idea with that one is that you could mount it on the end of a BLTouch, and the BLTouch could probe through the hole in the centre of the coil. Not sure if it has actually been tested, but could then be packaged with the BLTouch.

Ian

-

Just thinking out loud here, but what if you had a coil mounted upside down next to the bed. Use that one to scan the nozzle. Mount one on the toolhead for scanning the bed. That way it wouldn't matter if anything was stuck to the nozzle. Would it be accurate enough to set Z height that way?

-

@R4ffers I mentioned this in the blog post AFAIR - potentially useful, especially for multi axis printing where the bed autocalibration solution we have right now in Open5X relies on electrical contact. I have not had a chance to do experimentation yet. I may well require a different coil size and possibly more than one coil.

-

@T3P3Tony said in Duet 3 Scanning Z probe:

I may well require a different coil size and possibly more than one coil.

I thought the same, because otherwise the adjustment-macro would only know the nozzle is off, but not in which direction.

Fullsize metal detectors often have two or three overlapping coils. Wouldn't be a big issue to make a PCB with three layers on one side, I guess. -

Folks have been talking about magnets but what about a bed heater? I've got a 500x500x6.5mm aluminum bed with a full coverage 1600 watt heater on the bottom and PrintBite on top. As the probe passes over the heater wires, especially if they're energized (not to mention with PWM active), is there going to be an issue? I would think that 6.5mm of aluminum would help to dampen any variance but I'm curious if that was tested.

-

There is an option to turn off bed heaters during probing.

Reference M558 parameter B

Bn If 1, turn off all heaters while probing, default (B0) leaves heaters on.

Frederick

-

@fcwilt said in Duet 3 Scanning Z probe:

There is an option to turn off bed heaters during probing.

Reference M558 parameter B

Bn If 1, turn off all heaters while probing, default (B0) leaves heaters on.

Frederick

Ah yeah, I forgot about that. I never used it because probing currently takes long enough that, even with all that mass, the bed cools down a bit during the probe with the heater off. Shouldn't be an issue at this speed though, and de-energized, the wires aren't going to make a difference through 6.5mm of aluminum.

-

-

Here is an idea, a Klicky like probe that first picks a switch for a reference Z data and then a coil for fast scanning of the entire bed.

(Don't ask me how to do that).

-

@zapta I guess you could have a combination of switch and analog sensor in one housing. That would eliminate the time for double tool-pickup.

Just have to config the zprobe to be digital for the first probe point, then switch over to the analog sensor. -

@o_lampe, when the switch is pressed, it can change the characteristics of the sensor, e.g. disconnect it. This way there is not need to switch sensors. Just an idea.

-

Brain dump regarding using the probe as the only probe.

In theory it would be possible to use the probe as the only sensing equipment as it includes the only variable you need. which is an amplitude reading from the probe (which is then converted to distance)

The issue is there is no datum point, as depending on the scanned surface material, the activation distance could vary.

HOWEVER, assuming there is no minimum distance to the sensing coils, you could put the probe directly against the print surface and take a measurement to create a "zero" reference measurement and store that for later use.

In reality you may want to take various zero point measurements at different coil temperatures and create a look up table of sensitivity vs temperature.Then once the coils are mounted you would need to set a single Z-offset and that should be good enough.

There is another way off the top of my head, but I cannot remember the algorithms name where you can repeatedly move a reference plate (in this case the bed) up and down a known amount (say 1mm and 2mm) and then you can work out the differences in measurements to gain a pretty accurate depth to probe value. The math was complex the last time I checked, but once I find the name of it, ill post it here as it may be helpful.

-

@Notepad said in Duet 3 Scanning Z probe:

you could put the probe directly against the print surface

I see a problem here with the probes mounting screw heads. Are they countersunk or protruding? How accurate are they made.

It might be easier to use the nozzle as contact probe on a blank metall surface and use that height as reference. -

RRF.3.5.0 is not working for me and I got the error as "make" does not found path I was using eclipse ide for this. Msys2 file doesn't have make.exe in it. Can someone help me with this.

-

@Harish2811 please start a new thread

-

This post is deleted! -

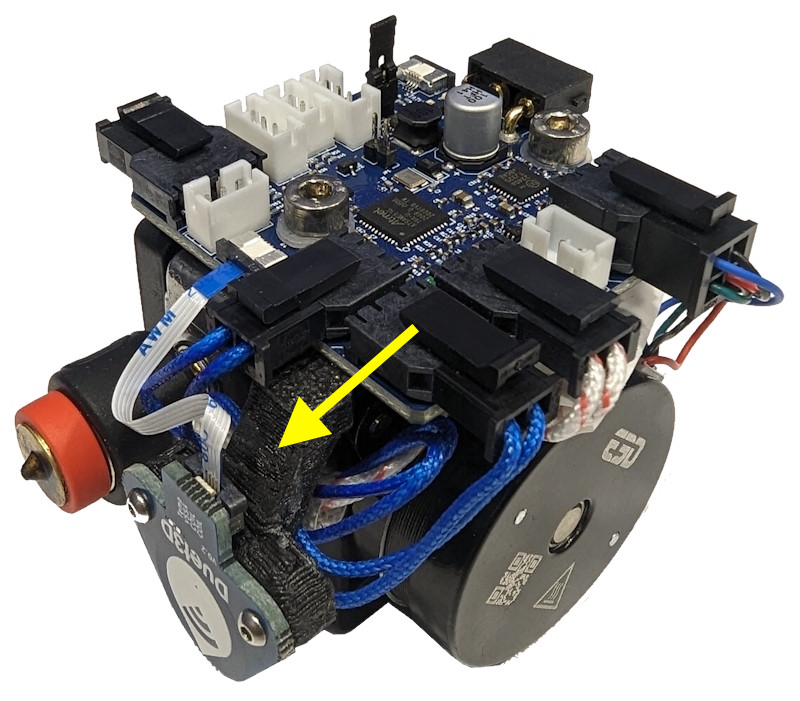

Is the STL / STEP for the probe holder availalbe that I see in the picture of the Revo toolboard?

-

What's the maximum distance the probe can be from the bed and still be effective? I need at least 4mm preferably more for my mount.

-

@edsped 4mm should be fine. We are doing more testing to establish maximums, including with different temperatures