Hollow shaft extruder

-

@tombrazier The best about these boards (there is also a similar mosquito board):

they only use parts that are/were in stock! Quite a challenge, I can tell from my own experience. -

@tombrazier said in Hollow shaft extruder:

Thanks @pakar. I have not explored the topology of BLDC motors so I have no idea how 12 coils and 14 motors would result in 8.5°. Part of me thinks wow, that's intriguing tell me more and part of me just wants to take it as read!

14 pole, 12 stator = 7 * 6 = 42 steps = 8.571 degrees.

I of course assume that it's a 3-phase motor and the number of stators need to be a multiple of the number of the number of phases.I tried looking for a good introduction but only found this, and that may be a bit too much as a introduction.

https://what-when-how.com/electric-motors/stator-winding-design-considerations-electric-motors/ -

@o_lampe Of course. I'm fully booked with work right now so it won't happen in at least 2-3 months. I live in Sweden so fairly close

The one i posted was stainless steel as a reflector. Only a non-reflective background would be needed.

Other option is a non-reflective slotted disk with a reflective background.

But not sure what field of depth the sensor has so using a non-reflective disk with a reflective background may be problematic.Either way i would recommend using a disk-material that won't wobble too much with the vibrations.

If you got a laser that would be perfect, and cheaper!

-

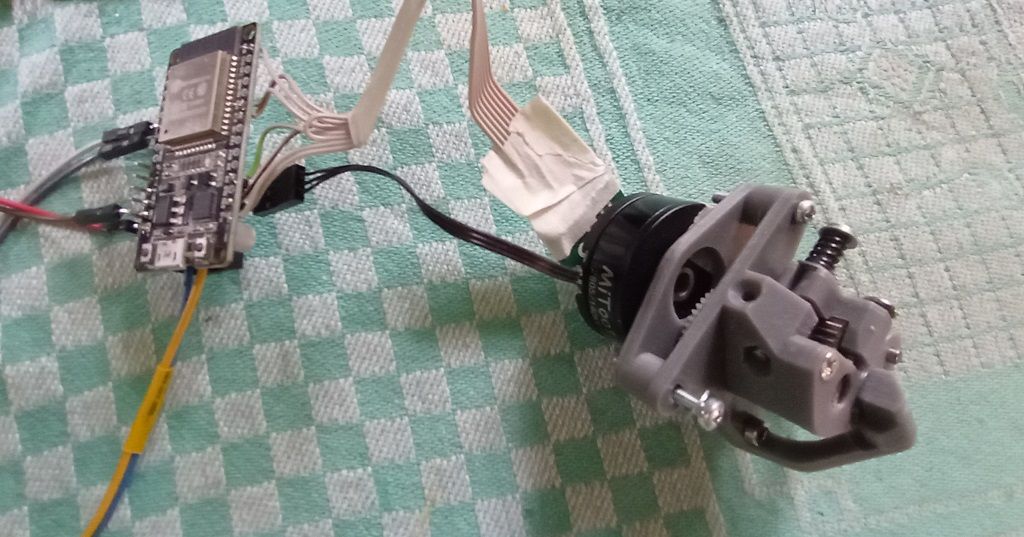

Had my first simpleFOC project running today. It was an old brushless gimbal controller without encoders and with 8bit mcu.

I was able to control two motors independently and relatively smooth (USB power only)

The atmega328 was also at it's limit, but I'm now confident it will work well with the right mcu. -

@o_lampe What motor driver did you use?

-

@tombrazier The drivers on the old gimbal controller are L6234D.

Not the same type as the current DRV8301, but they were used to develop simpleFOC at the beginning. -

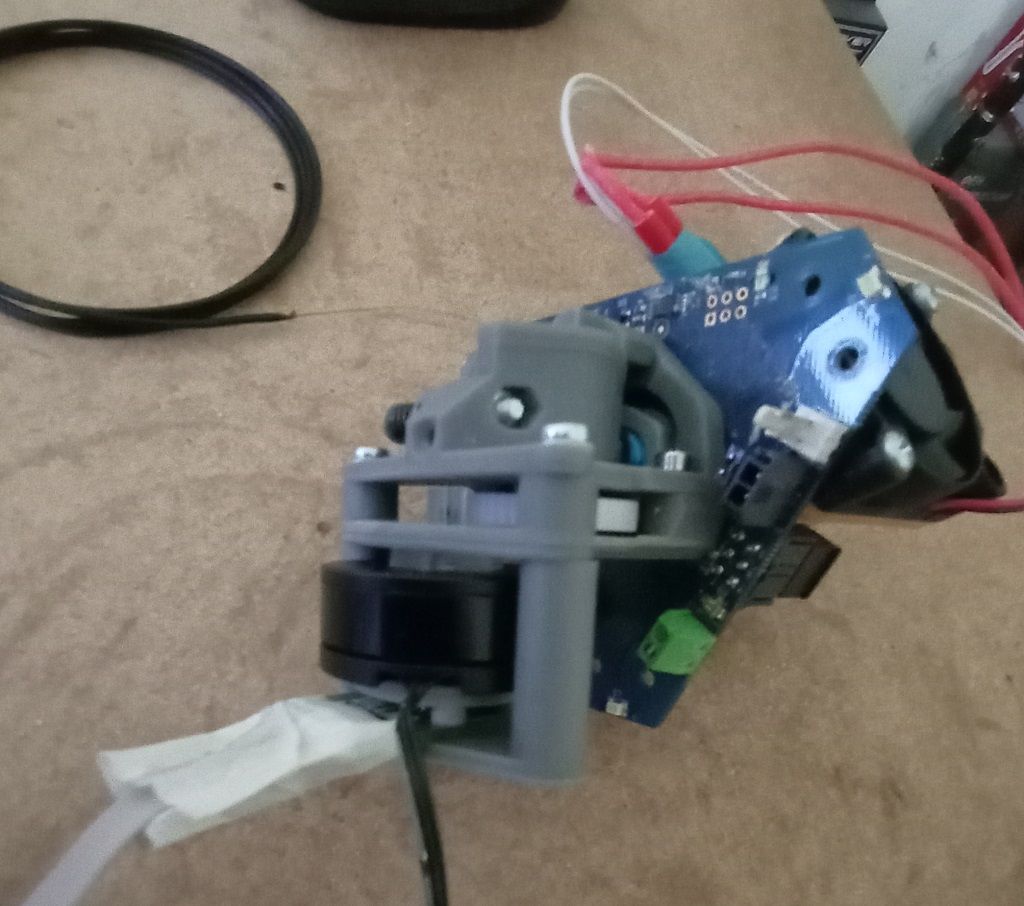

Today I had the first test with the step-dir interface of simpleFOC.

It was a bit of a learning curve to get it working with the magnetic sensor I had.

Running the motor in open loop is no option, the motor gets pretty hot.

In closed loop the motorcurrent is reduced to the actual required torque.

I wanted to give it a real-world extruder-test and ran a typical gcode, but with the XYZ steppers absent, I got tons of errors. (motorphase disconnected)

I wonder how I can get rid of those messages? -

@o_lampe set the motor currents on XYZ to 0, that should stop the errors

-

@o_lampe you could just connect some resistors with the same resistance as a normal stepper motor winding and set the current really low.

I'm guessing that shouldn't break anything and would fool the board into thinking a stepper is connected...Or just connect any random spare motors you may have lying around...

Just a thought...

-

Thanks all for the tips, it's running now.

Just had to add thermistors

It's fun to see the motor almost jump off the table when retracting

-

@o_lampe from another thread, courtesy of @chrishamm

If you set the motor current [...] to less than 500mA, you should not get any "phase disconnected" warnings even if you leave it disconnected.

-

@oliof Thanks, that's what I did.

And adding a thermistor, because I just took the SD-card from my Delta printer and wanted to keep the config.g as original as possible.It will take a while, before I can test the setup on any screw extruder, so I thought of a different way to test the BLDC in a real scenario.

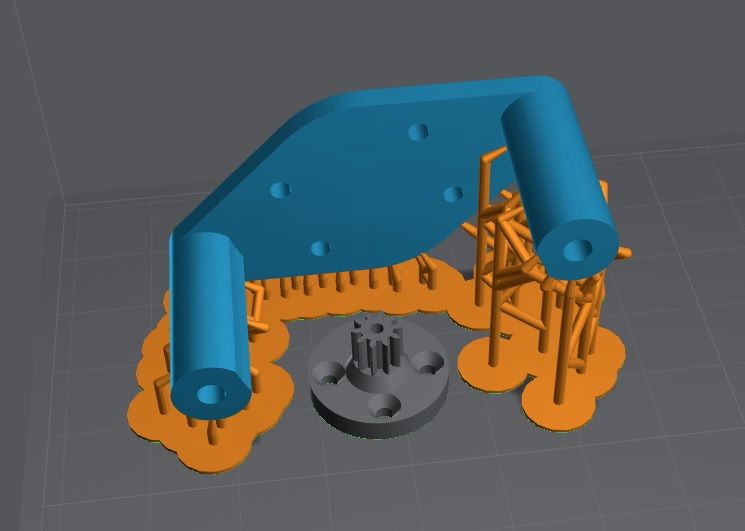

What If I mount it to my sherpa mini instead?

-

Guess, what's printing right now

Wondering how long the gear will last. In my harmonic drive experiments, they lasted a few days with a medium load.

-

Did a longer torture test with the BLDC-sherpa.

I was able to extrude PLA+ at 210°C with 6mm/s => 14mm^3 .

The resin-spur gear was the limit, but motor and simpleFOC driver were still cold.IIRC, my NEMA14 stepper can only extrude at 3mm/s.

I think, I will mount it permanently on my Delta and make some speed-benchys.

-

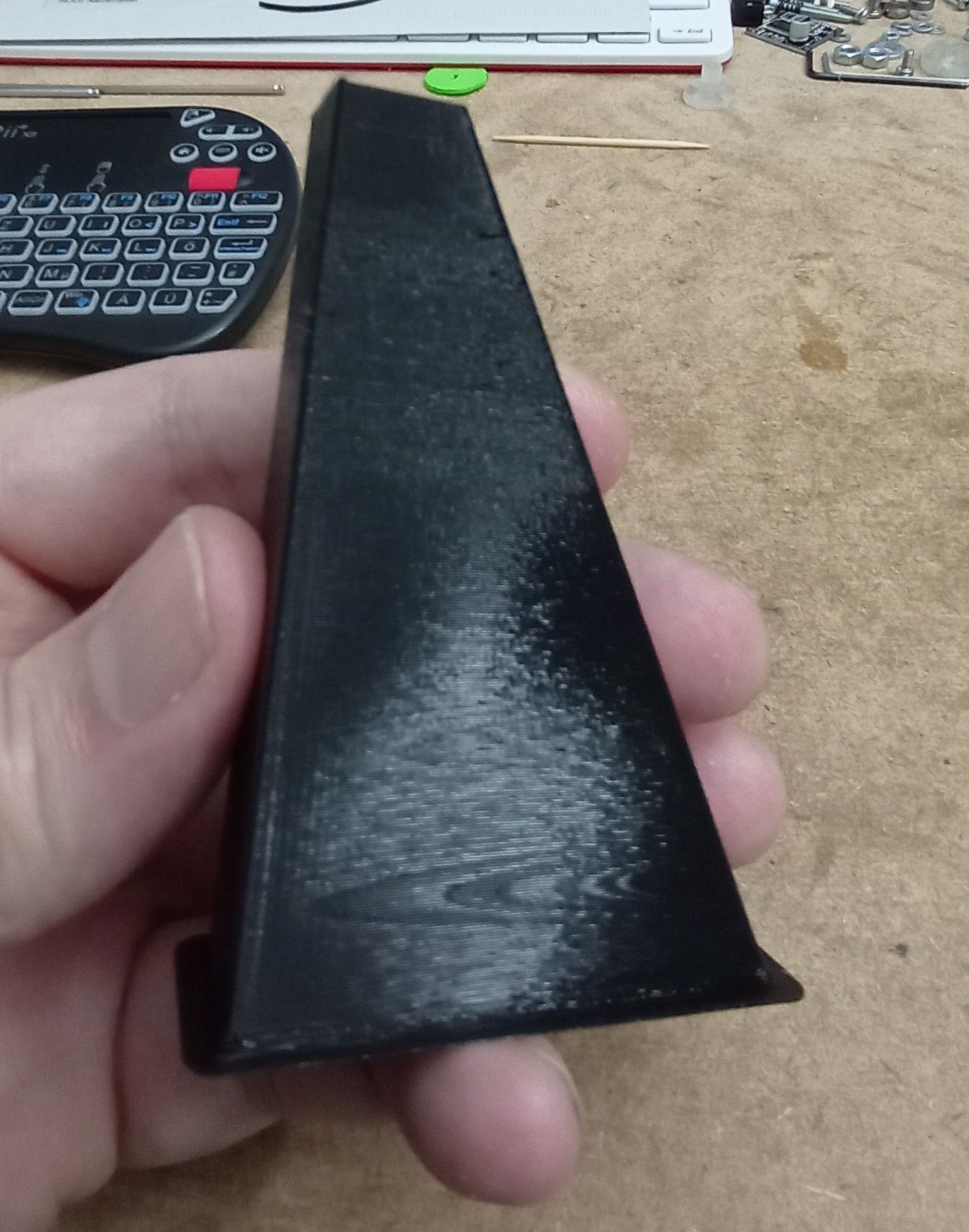

First print today

Instead of a benchy, I tried the extruder-woodgrain test. Yes there is some, but hardly visible. The corners were sharp and even, that was a relieve. The close loop PID setting are quite soft, so I expected worse...

At the top third, the printspeed got so low, that the filament overheated. 10°C less temp and it was nice and shiny again.

-

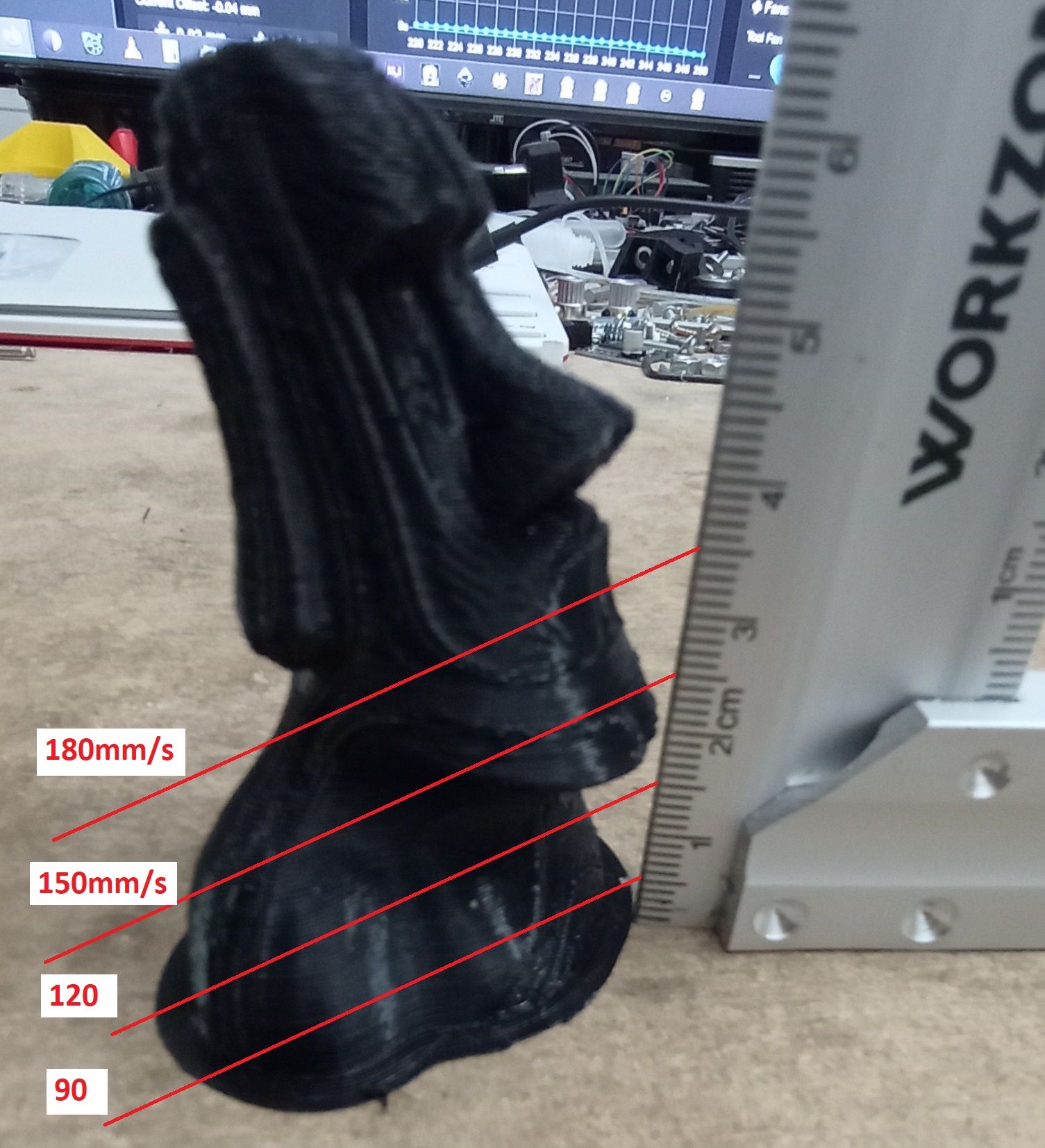

Speed test : done

I printed a dual color Moai head with 0.25mm layer height and increased speed until it reached 180mm/s (technically, not always real speed)

It wasn't the BLDC extruder that got in trouble. I saw lots of ringing, but upto 150mm/s I saw no signs of under extrusion.

If my math is correct, 0.25mm * 0.4mm *150mm/s = 15 mm^3 volumetric flow?

-

Great work. I'm keen to see how this works with VDE when I get the time for it.

Are you not using input shaping for the ringing?

-

@tombrazier Send my some grinded bearings and I can test it

I'd trade it in for a resin-printed carrier...I'm using input shaping, but it was tuned for 80mm/s. Any other speed and it's off.

I was under the impression, that it doesn't work well on deltas anyway? -

@o_lampe Happy to grind and send some bearings. E-mail me at tom at firstsolo dot net.

IS with delta is possible in principle. I understand resonances might vary across the print bed, though. They should not vary with speed. Marlin only has IS on two axes at present (I'd love to have the time to fix this one day!) so deltas are not really supported for IS. I have no idea whether RRF or Klipper have IS for deltas. As I understand it, though, RRF's IS implementation may have issues for any printer. If I have understood correctly then RRF attempts just to do IS on corners which makes a mess with short segments.

-

@tombrazier RRF does support input shaping on deltas but not on other nonlinear kinematics.