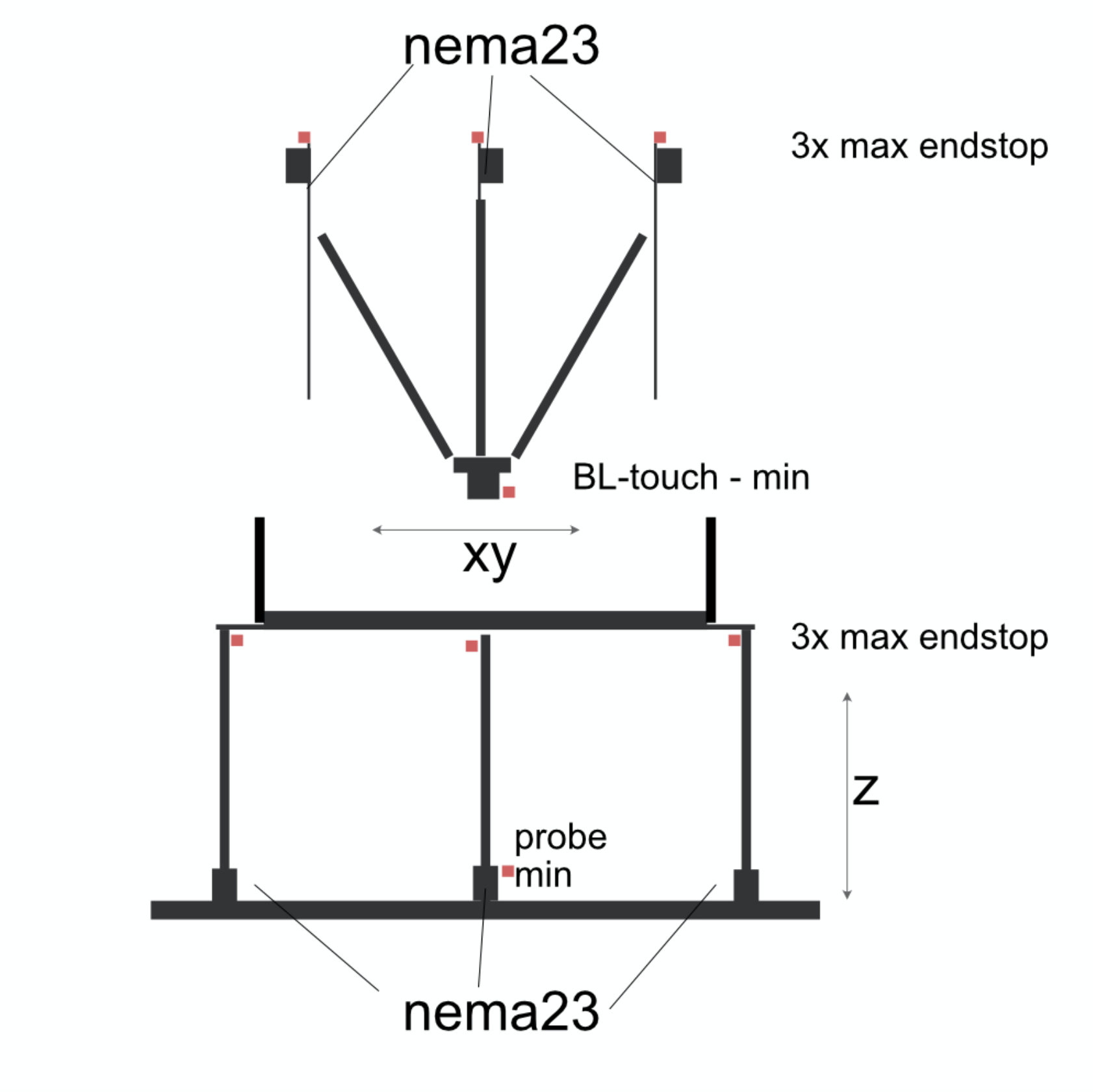

Delta-3D-printer with moving print bed in z

-

Hi all,

I am trying to convert a self build delta-printer into a Delta printer with a moving print bed in-z. The goal is, to use the machine as a custom- 3d printer, like a big powder printer. Therefore I need to oversize the print-bed, due to its weight.

I am working with a Duet3 Hc36, the Delta-Arms are moved by 3xNema23 connected to a external high-current stepper driver. The Print bed is planned to be moved via 3xNema23 stepper and 3 separate high current stepper drivers, each with its own max. endstops. Summarising, the delta printer always prints xy at the same height, and moving into the next layer is done by the print bed. (Similar to a powder printer)

Here my question:-

Has this been done before? I couldn't find any discussion related to it.

-

regarding hardware: What kind of extension do I need, is the duet3Expansion3HC what I am looking for ? ( 3 Motors, 3xmax. Endstop, 1global min. Probe). Can someone give me a brief understanding of the wiring.

-

How can I assign this new z-axis in ( configtool.reprapfirmware.org/Motors ), or do I need to add en Extruder E1 and copy the Z-value to it? and also replace the actual Z-value via text edit.?

thank you in advance, for all the comments/ help

best, JAN

-

-

I can think of a possible work around.

If it's possible to read the absolute z position from the object model, you could have a macro called at each layer change (from the slicer custom gcode section).

The macro could compare Z to the ideal height, calculate the difference and do a G91 upward move of that amount to reset Z (then change back to G90), and apply the same move downward to the bed axis; probably W, by convention.

The rest of the system would "know" nothing of the mechanical difference and the G code would be normal, with Z apparently moving up all the time - but due to the regular G91 moves, it would stay at the same height.

Edit - I cannot find values for axis offsets in the object model viewer; I'd guess it is stored internally?

@DC42 - Is this available, directly or indirectly?

(The difference between workpiece axis position and G53 position?)edit; sprelling / typo.

-

@naj

Things like 3 motors for Z axis isn't implemented yet in config tool. You'd have to change it manually, also change the endstop config.To keep the Delta from applying layer changes to the delta motors, you could use babystepping at each layer change and revers the layer change. Then apply it to a new defined W-axis, which are the three bed motors.

You could still see issues from mesh-levelling and Delta calibration, but it's worth a try.

-

@naj I don't think this has been done before. The obvious question to me is: what's the point? One of the big advantages of the delta configuration is that the bed is fixed, so it can be as heavy as you like, and any high-voltage wiring to the bed heater doesn't need to move can be kept out of harms way. Why not use taller towers? Yes they may need to be thicker if you make them taller, but that's a lot simpler than making the bed movable too.

If you do want to go ahead with this:

-

RepRapFirmware allows you to add additional towers and additional linear axes to the delta kinematics. The towers have to be the first three "axes", so you would need to call your Z axis something else, for example U, and create it as an additional linear axis using M584.

-

To print, one option would be to pre-process the GCode file to replace all instances of Z by U. If you use firmware retraction, then any Z hop will still be done by the arms, which is probably sensible because they will move faster than the bed.

-

To drive the seven motors, one option is to driver the extruder motor from a tool board (if the current it needs is within the capability of the tool board) and the remaining 6 motors from the 6HC. Alternatively, use a 3HC expansion board.

HTH David

-

-

dont know why you want to reinvent the Delta...to move the printhead in YX direction all the stepper have to move x amount....and to change z all have to move all the same amount..so..the Z-Direction is built in any Delta...so why make it overcomplicated and use another 3 stepper to move Z? Its not even overengineered...its just hmm stupid to remove all advantages of a Delta printer

-

@barracuda72

Maybe there's a reason for it? A powder printer with a Delta driven Laser head for instance -

@barracuda72 @o_lampe thx,

I think it is the easiest way to print inside a container filled with liquid.The idea is that the print-bed is inside a container, filled with liquid, the 3dprinted structure will cause a reaction with the liquid - this transforms the printed material.(So after printing in the dry (Z-0)-the 3d-object will sink during the continuation of the print, in the liquid (z-))

I admit it is a very experimental approach, if you can think of any simpler procedures/ method, I am open to anything. -

Pretty sure I saw something like this at MRRF...

https://www.youtube.com/watch?v=L9pTHMi5SP8

Yup here it is.