Have you ever observed this layer thickness problem?

-

Hi,

This problem has been a huge challenge for me and I was wondering if anybody else had this problem.

I have observed that objects with certain features, like holes, modified the layer thickness at that layer. This effect is not very visible with organic shapes, like statues or figurines, but quite obvious for objects with straight walls. One object where this problem is very obvious is the XY-test object file from Make 2016/2017 3D Printer Test (https://www.thingiverse.com/thing:2071696/files) . Here's a picture demonstrating the problem (I've printed it at 120% scale, it made the problem more visible):

The leftmost picture is where the problem is most obvious. There is a very regular band whenever there is a hole (there is a second hole on the object but it isn't visible on the picture, however its artefact is). The opposite wall (second picture) has the same problem but it is inverted (it is as if there was a layer shift). However, when I look at the external walls (third and forth pictures), there is no layer shift at all (at least it isn't visible as prominently).

Now whenever I asked this question on other forums I got some suggestions about the belts not being tight enough or being too tight. I don't believe that's the problem, as the artefact is too regular and not equally visible on both sides. I don't think this is a temperature problem (there is no fluctuations on the hotend and the bed was turned off). The artifeact is visible on Prusa Slicer, Cura, and Simplify 3D (the pictures are forum Prusa Slicer version), so I don't think this is related to the slicers too (they all print the object the same way: Regular one sided movements on parts without the walls, and 180 degree returns at the holes. Interestingly no slicer tries to print the layers with the hole by moving stragiht, going past the hole by retracting and continuing from the other side of the hole. I wonder if the results would be different if they printer like this). The object itself looks very straight without artifacts when loaded to the slicers, so I don't think this is a problem with the object's design (one problem could be that there are 2 versions of this object, one with 0.8 mm thick walls and one with 1 mm thick walls, however the problem is visible on both of them, but slightly less prominent on 1 mm object). My extruder is calibrated (it is a standard BMG and I've performed the extruder calibration a few times).

I am out of ideas. Maybe this is a problem with all of the slicers, making some approximations, which become visible at certain parts. Maybe it is specific to Duet (I'd highly doubt it). Maybe it is a problem with how slicers calculate extrusion amount and it changes at each layer (so each layer's thickness is slightly different). Maybe it is a limitation of the FDM process itself.

Do you have any theoies/ideas? Have you ever tried to print this object?

-

@drmaestro I just printed one and it came out EXACTLY like your.

Rostock Max V3.2 running Duet2/Ethernet firmware revision 3.2

I'll experiment with pressure-advance and see if I can get it to print a little better.

-

I have seen something similar on a regular basis - not that bad though. I have gotten used to it

I will be watching with great interest to see what people have to say. -

@drmaestro If you load the gcode in to something like Repetier which will draw from the code can you see it? You could also try putting the stl in Fusion 360 to look at the mesh or Netfab. May give you more evidence

-

The change of direction on the layers with the holes making a horse shoe shape is probably the culprit. The other full circle layers don't have that change of direction. So the slow down is probably the cause. Adjusting pressure advance might help.

Post your full config and print settings as well.

-

@alankilian Thank you very much for sparing some time for printing the object. I am somehow relieved to see that it isn't specific to my printer only.

@3DPMicro The GCode looks perfectly fine when loaded on a GCode viewer. The walls are straight. The STL itself has no visible problems when loaded in Solidworks. It looks as it is intended to look.

@phaedrux The horseshoe shape can be a problem but that is the preferred method for all of the slicers I've tried. None of the slicers try to make that hole by retracting and going straight accross the hole. Maybe that is a fundamental error with the slicers themselves, who calculate the amount of plastic needed. The pressure advance might change how this looks but don't you think it is a huge amount of overextrusion for it to deal with? The pressure advance, especially on a direct drive extruder, isn't supposed to make that much of a change. While this part has been printed without pressure advance, I've used pressure advance in the past and I can still see the same artifacts.

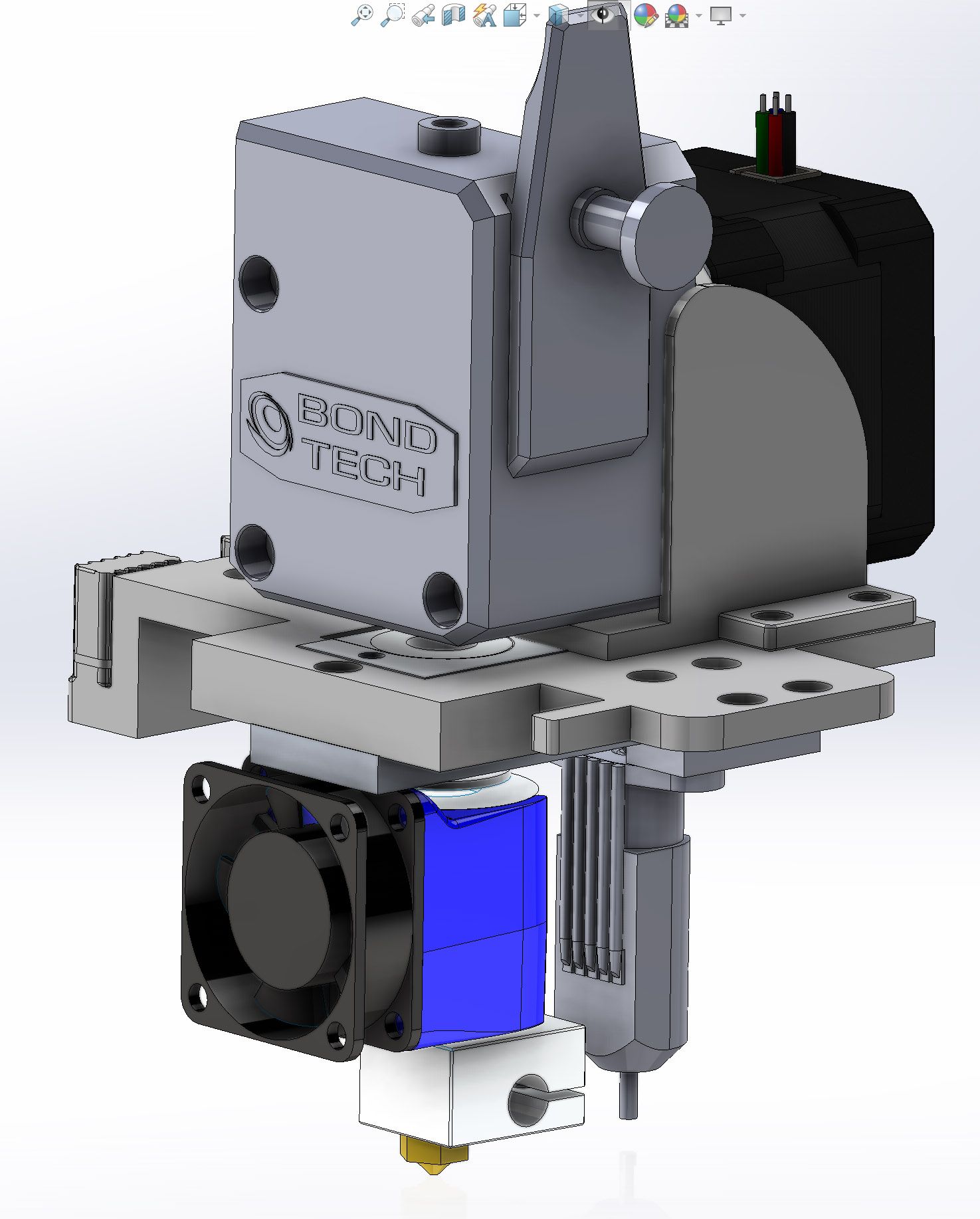

Some more information about my configuration: It is a custom cartesian printer with Duet Wifi 1.04, running firmware 3.2. Bondtech BMG extruder.

.

Here's my config.g:; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Fri May 14 2021 14:28:05 GMT+0300 (GMT+03:00) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Sigma 3D" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E830.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X7200.00 Y7200.00 Z180.00 E2400.00 ; set maximum speeds (mm/min) M201 X700.00 Y700.00 Z30.00 E700.00 ; set accelerations (mm/s^2) M906 X1400 Y1500 Z1400 E900 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-20 Y0 Z0 S1 ; set axis minima M208 X235 Y220 Z230 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin !xstop M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin !ystop M574 Z0 P"nil" ; Z has no endstop ; Z-Probe M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T4800 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X29 Y0 Z0.75 ; set Z probe trigger value, offset and trigger height M557 X30:190 Y5:195 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 R2.322 C219.7 D9.80 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0:2 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue T0 ; select first toolHere are some settings for the print that I've copied from the GCode:

; generated by PrusaSlicer 2.3.1+win64 on 2021-05-15 at 16:38:11 UTC ; ; external perimeters extrusion width = 0.45mm ; perimeters extrusion width = 0.45mm ; infill extrusion width = 0.45mm ; solid infill extrusion width = 0.45mm ; top infill extrusion width = 0.40mm M107 G10 S210 ; set temperature ;TYPE:Custom M561;Clear bed transforms G28 XY; Home X and Y axis M280 P3 S10 I1; BLTouch Pin down G1 X100 Y100; Go to 100 G28 Z; G29 S1 ; Bed leveling with already recorded height map M280 P3 S90 I1; BLTouch pin up G10 S210 ; set temperature M116 ; wait for temperature to be reached G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion ; Filament gcode ; filament used [mm] = 2126.85 ; filament used [cm3] = 5.12 ; total filament used [g] = 0.00 ; total filament cost = 0.00 ; estimated printing time (normal mode) = 57m 56s ; avoid_crossing_perimeters = 0 ; avoid_crossing_perimeters_max_detour = 0 ; bed_custom_model = ; bed_custom_texture = ; bed_shape = 0x0,200x0,200x220,0x220 ; bed_temperature = 0 ; before_layer_gcode = ; between_objects_gcode = ; bottom_fill_pattern = monotonic ; bottom_solid_layers = 2 ; bottom_solid_min_thickness = 0 ; bridge_acceleration = 0 ; bridge_angle = 0 ; bridge_fan_speed = 100 ; bridge_flow_ratio = 1 ; bridge_speed = 60 ; brim_width = 0 ; clip_multipart_objects = 1 ; color_change_gcode = M600 ; complete_objects = 0 ; cooling = 0 ; cooling_tube_length = 5 ; cooling_tube_retraction = 91.5 ; default_acceleration = 0 ; default_filament_profile = ; default_print_profile = ; deretract_speed = 0 ; disable_fan_first_layers = 3 ; dont_support_bridges = 1 ; draft_shield = 0 ; duplicate_distance = 6 ; elefant_foot_compensation = 0.2 ; end_filament_gcode = "; Filament-specific end gcode \n;END gcode for filament\n" ; end_gcode = M104 S0 ; turn off temperature\nM140 S0 ; turn off bed\nG28 X0 ; home X axis\nM84 ; disable motors\n ; ensure_vertical_shell_thickness = 0 ; external_perimeter_extrusion_width = 0 ; external_perimeter_speed = 50% ; external_perimeters_first = 0 ; extra_loading_move = -2 ; extra_perimeters = 1 ; extruder_clearance_height = 20 ; extruder_clearance_radius = 20 ; extruder_colour = "" ; extruder_offset = 0x0 ; extrusion_axis = E ; extrusion_multiplier = 1 ; extrusion_width = 0 ; fan_always_on = 1 ; fan_below_layer_time = 60 ; filament_colour = #29B2B2 ; filament_cooling_final_speed = 3.4 ; filament_cooling_initial_speed = 2.2 ; filament_cooling_moves = 4 ; filament_cost = 0 ; filament_density = 0 ; filament_diameter = 1.75 ; filament_load_time = 0 ; filament_loading_speed = 28 ; filament_loading_speed_start = 3 ; filament_max_volumetric_speed = 0 ; filament_minimal_purge_on_wipe_tower = 15 ; filament_notes = "" ; filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6" ; filament_settings_id = "PLA No Heated Bed" ; filament_soluble = 0 ; filament_spool_weight = 0 ; filament_toolchange_delay = 0 ; filament_type = PLA ; filament_unload_time = 0 ; filament_unloading_speed = 90 ; filament_unloading_speed_start = 100 ; filament_vendor = (Unknown) ; fill_angle = 45 ; fill_density = 20% ; fill_pattern = grid ; first_layer_acceleration = 0 ; first_layer_bed_temperature = 0 ; first_layer_extrusion_width = 0 ; first_layer_height = 0.2 ; first_layer_speed = 30 ; first_layer_temperature = 210 ; full_fan_speed_layer = 0 ; gap_fill_speed = 20 ; gcode_comments = 0 ; gcode_flavor = reprapfirmware ; gcode_label_objects = 0 ; high_current_on_filament_swap = 0 ; host_type = octoprint ; infill_acceleration = 0 ; infill_anchor = 600% ; infill_anchor_max = 50 ; infill_every_layers = 1 ; infill_extruder = 1 ; infill_extrusion_width = 0 ; infill_first = 0 ; infill_only_where_needed = 0 ; infill_overlap = 25% ; infill_speed = 60 ; interface_shells = 0 ; ironing = 0 ; ironing_flowrate = 15% ; ironing_spacing = 0.1 ; ironing_speed = 15 ; ironing_type = top ; layer_gcode = ; layer_height = 0.2 ; machine_limits_usage = emit_to_gcode ; machine_max_acceleration_e = 10000,5000 ; machine_max_acceleration_extruding = 1500,1250 ; machine_max_acceleration_retracting = 1500,1250 ; machine_max_acceleration_x = 9000,1000 ; machine_max_acceleration_y = 9000,1000 ; machine_max_acceleration_z = 500,200 ; machine_max_feedrate_e = 120,120 ; machine_max_feedrate_x = 500,200 ; machine_max_feedrate_y = 500,200 ; machine_max_feedrate_z = 12,12 ; machine_max_jerk_e = 2.5,2.5 ; machine_max_jerk_x = 10,10 ; machine_max_jerk_y = 10,10 ; machine_max_jerk_z = 0.2,0.4 ; machine_min_extruding_rate = 0,0 ; machine_min_travel_rate = 0,0 ; max_fan_speed = 100 ; max_layer_height = 0 ; max_print_height = 200 ; max_print_speed = 80 ; max_volumetric_speed = 0 ; min_fan_speed = 100 ; min_layer_height = 0.08 ; min_print_speed = 10 ; min_skirt_length = 0 ; notes = ; nozzle_diameter = 0.4 ; only_retract_when_crossing_perimeters = 0 ; ooze_prevention = 0 ; output_filename_format = [input_filename_base].gcode ; overhangs = 1 ; parking_pos_retraction = 92 ; pause_print_gcode = M601 ; perimeter_acceleration = 0 ; perimeter_extruder = 1 ; perimeter_extrusion_width = 0 ; perimeter_speed = 50 ; perimeters = 3 ; physical_printer_settings_id = ; post_process = ; print_settings_id = Sigma 3D ; printer_model = ; printer_notes = ; printer_settings_id = Sigma 3D ; printer_technology = FFF ; printer_variant = ; printer_vendor = ; raft_layers = 0 ; remaining_times = 0 ; resolution = 0 ; retract_before_travel = 0.5 ; retract_before_wipe = 0% ; retract_layer_change = 0 ; retract_length = 0.8 ; retract_length_toolchange = 10 ; retract_lift = 0 ; retract_lift_above = 0 ; retract_lift_below = 0 ; retract_restart_extra = 0 ; retract_restart_extra_toolchange = 0 ; retract_speed = 40 ; seam_position = aligned ; silent_mode = 1 ; single_extruder_multi_material = 0 ; single_extruder_multi_material_priming = 1 ; skirt_distance = 4 ; skirt_height = 1 ; skirts = 4 ; slice_closing_radius = 0.049 ; slowdown_below_layer_time = 5 ; small_perimeter_speed = 20 ; solid_infill_below_area = 5 ; solid_infill_every_layers = 0 ; solid_infill_extruder = 1 ; solid_infill_extrusion_width = 0 ; solid_infill_speed = 20 ; spiral_vase = 0 ; standby_temperature_delta = -5 ; start_filament_gcode = "; Filament gcode\n" ; start_gcode = M561;Clear bed transforms\nG28 XY; Home X and Y axis\nM280 P3 S10 I1; BLTouch Pin down\nG1 X100 Y100; Go to 100\nG28 Z;\nG29 S1 ; Bed leveling with already recorded height map\nM280 P3 S90 I1; BLTouch pin up\n ; support_material = 0 ; support_material_angle = 45 ; support_material_auto = 0 ; support_material_buildplate_only = 0 ; support_material_contact_distance = 0.2 ; support_material_enforce_layers = 0 ; support_material_extruder = 1 ; support_material_extrusion_width = 0 ; support_material_interface_contact_loops = 0 ; support_material_interface_extruder = 1 ; support_material_interface_layers = 1 ; support_material_interface_spacing = 0 ; support_material_interface_speed = 100% ; support_material_pattern = rectilinear ; support_material_spacing = 3 ; support_material_speed = 60 ; support_material_synchronize_layers = 0 ; support_material_threshold = 45 ; support_material_with_sheath = 0 ; support_material_xy_spacing = 50% ; temperature = 200 ; template_custom_gcode = ; thin_walls = 1 ; threads = 8 ; thumbnails = ; toolchange_gcode = ; top_fill_pattern = monotonic ; top_infill_extrusion_width = 0 ; top_solid_infill_speed = 30 ; top_solid_layers = 3 ; top_solid_min_thickness = 0 ; travel_speed = 90 ; use_firmware_retraction = 0 ; use_relative_e_distances = 1 ; use_volumetric_e = 0 ; variable_layer_height = 1 ; wipe = 0 ; wipe_into_infill = 0 ; wipe_into_objects = 0 ; wipe_tower = 0 ; wipe_tower_bridging = 10 ; wipe_tower_no_sparse_layers = 0 ; wipe_tower_rotation_angle = 0 ; wipe_tower_width = 60 ; wipe_tower_x = 180 ; wipe_tower_y = 140 ; wiping_volumes_extruders = 70,70 ; wiping_volumes_matrix = 0 ; xy_size_compensation = 0 ; z_offset = 0I was wondering, if more people are willing to print this object and post a picture.

-

@drmaestro said in Have you ever observed this layer thickness problem?:

I was wondering, if more people are willing to print this object and post a picture.

I have a 0.4mm and 0.8mm nozzle running ATM, so I could give it a try. Wondering, how the slicer will do the 0.8mm version?

-

@o_lampe That should be interesting. The line width could also be a problem, as the slicer generally uses a slightly larger line width compared to the nozzle (0.45-0.46 instead of 0.4) but I don't think that's the problem, as the same line width will be used for the entire object and any error in wall thickness will be applied to everywhere, so there should be no visible changes.

I changed the nozzle size in Prusa slicer to see how it draws the GCode. As the wall thickness is 0.8 mm, it just creates a single line and goes through the hole instead of looping, so in theory, the artifact shouldn't be visible (It has a similar behaviour for 1 mm thick version too).

-

@drmaestro

I found the same with the 0.8 nozzle, it retracts and starts on the other side.

The 0.4 result is different than yours, I don't see a thicker wall, but an offset where the holes are. I use ArcWelder as post processor BTW.

Here's my pic, the black is 0.8mm showing signs of bad calibrated retraction (also bowden tube issues)

The other is held against the light to see transparency differencies.

My 1st conclusion is, that the horseshoe move induces rounding errors in RRF. (or ArcWelder?)

-

Would be interesting to see someone with RRF2.x or even older ( pre- RTOS times) would try that...

-

@o_lampe The pictures you've posted are from the outside of the object, where the effect is less visible. How does it look from the inside? In my case, the artifact is much more pronounced if you look at the inside walls. The lighting is also very important to be able to see the artifact (for example, in my third picture, it looks like there is no artifact at all at the inside wall, but if you shine the light with the appropiate angle (I used a flashlight) it is visible.

I have tried with and without Arc Welder, there is no visible difference.

Also, a funny coincidence, here's a post I've made 4 years ago, for the same problem in the RepRap forums, guess who did one of the answers belong to

https://reprap.org/forum/read.php?262,760790,760965#msg-760965 -

Is there a gcode visualiser that shows direction of travel and velocity of movement? If there is I wonder if that would show a correlation with the artefacts you are seeing. I see a similar effect with the good old xyz calibration cube and have always assumed it is down to the different travel direction/speed used for the outer wall when printing the parts of the cube with letters on them.

-

@drmaestro it looks to me that you have backlash in the axis that moves perpendicular to the long face of that object. This backlash causes a difference in position depending on whether that part of the perimeter is printed clockwise or anticlockwise, which in turn is affected by holes in the faces.

-

@dc42 I know that this is the first thing that comes to the mind when seeing this problem, however I am not sure about it. My reasons:

- The object is being printed with the inner perimeters first, so it starts regularly, but then makes the horseshoe turn. This would imply the artefatct to be more visible on the exterior surfaces as the extrusion starts regularly .

- I am using idlers which can be tensioned using bolts and I am using a voice frequency analyzer to tension the belts. They run very straight, with no wobble (I had wobble in the past, which I have corrected now).

- The artefact is extremely regular

- The wall thickness changes depending on the features on the object, so when there is a hole, the wall is thicker and I did cut with a cutter to see if there is a gap between the inner and outer walls, but there isn't any.

- The artefact exists on both X and Y axis

Could it be a side effect of interpolation ? (I don't know how it works, so that might be completely unrelated).

Have you ever printed that object?

-

@dc42 said in Have you ever observed this layer thickness problem?:

@drmaestro it looks to me that you have backlash in the axis that moves perpendicular to the long face of that object. This backlash causes a difference in position depending on whether that part of the perimeter is printed clockwise or anticlockwise, which in turn is affected by holes in the faces.

I'm printing on a Delta and got a near identical print.

Does it seem possible for backlash to be similar on such different printers?

I'm in the middle of not having much luck getting better prints by adjusting Pressure Advance.

-

@drmaestro Personally, I don't buy the backlash theory because it's difficult to imagine how that could happen on a CoreXY - a Cartesian maybe but not a CoreXY.

Are the external perimeters always laid down first/last or does that vary? It reminds me of a similar effect I've seen when printing a solid top layer using a mixing hot end. In this case, it shows as a variation in colour depending on whether the 45 degree infill is being laid down from left to right or if there is a change in direction from right to left. The colour of the mixed extruded filament will vary depending on which side of the "bead" is supported.

So in the case of an external perimeter, the thickness of the bead will depend on whether there is a previous bead of filament that the new bead butts up against or not. i.e. if the external perimeter is done before the infill, then it's like;y to be a different thickness than if it's done after the infill. Could that be what's happening?

-

@alankilian i used to have a V2 and always seen that problem. The real problem (for Delta) is that is really difficult to make the effector to stay flat with the bed surface independently from the direction it is travelling. If you look close when printing, the effector would probably tilt a little bit when switching direction. Also a very little tilt could lead to this because the nozzle is far from the center of the rotation.

So this shows up when a line is lay down in +X direction and the next one in -X direction from example.

I left delta because they need to be really rigid to work properly and seemecnc's one are not so good at this (mine was made in wood so it was the worst case). -

@deckingman Maybe. A problem with this object (with 0.8 mm thick wall) is that the slicer doesn't really consider it as an object with an internal and external perimeter. The fact that it is making a horseshoe turn makes the line a closed single loop, so a single line in fact, even though there should be two lines. I've loaded the 0.8 mm and 1 mm objects, and also another object with thicker walls to Prusa Slicer. Here's how they look at thelevel of a hole:

The object on the bottom has external perimeters (orange) and internal perimeters (yellow). The object on top and right is the 0.8 mm object and it only has orange perimeters, so only external. The obejct on top left is the 1 mm object and while it has some gap fill between the perimeters, they still are external perimeters according to the color. Maybe that's the problem?

So in this object's case, the object starts printing form the external line (even though internal perimeters first is selected) from a very close location to the hole, goes a few cm towards the hole, makes its 180 degree turn and goes to the internal line, finishes that line at the other end of the hole and makes its second turn to finish the external line (I have chosen aligned seems so it starts from very similar locations). Even if I chose to print with the external perimeters first option, it still performs the same trajectory (probably as a result of not having an internal perimeter) .

-

@drmaestro Another possibility is that although I don't buy the backlash in the gantry/carriage theory, is your hot end solidly mounted? Does it flex like a groove mounted V6?

-

@deckingman It used to flex a little bit when I was using groove mount on plastic version of my X car. So, I've bought an adapter (this one https://www.aliexpress.com/item/32890582038.html?spm=a2g0o.productlist.0.0.727965c11yqaj9&algo_pvid=a5da6614-4232-4c0e-ba6f-5602b69cf33f&algo_expid=a5da6614-4232-4c0e-ba6f-5602b69cf33f-14&btsid=0b0a555516211823561961742eb46d&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_) , so it is metal on metal now. There was a very slight movement due to tolerances (or bad manufacturing), so I designed a plastic part that plugs to it and ifxes it in place.

There is no movement if you try to move the hotend (of course it is still bolted to plastic and the plastic can flex but I don't imagine it would flex during routine printer movements).