Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11

-

I added a new macro, Hotmesh.

"Hotmesh" preforms bed a mesh probing routine with a heat stabilized bed. This macro will heat the bed based on the currently set system filament type, wait 5 minutes for the bed temperature to stabilize, and then perform mesh probe. Once initiated, the nozzle will rise to 150mm and then lower 15mm for every 30 seconds elapsed - about 5 minutes in total. Once the nozzle is at the bed, the mesh probing cycle will commence.; 0:/macros/hotmesh.g ; Called to perform automatic heated bedmesh compensation T0 ; Ensure tool is selected M703 ; Heat bed to set temp based off current system filament type M104 S-273 ; Turn off hotend M106 S0 ; Turn part cooling blower off if it is on M291 P{"Performing bed heatup per " ^ move.extruders[0].filament ^ " profile. This process will take approximately 6 minutes."} R"Hotmesh" S0 T10 G28 ; Home G1 X100 Y100 ; Place nozzle center of bed ; Give 5 minutes for stabilization G91 ; Set to Rel Positioning while iterations <=9 ; Perform 10 passes G1 Z15 ; Move Z 15mm up G4 S0.5 ; Wait .5 seconds M116 ; Wait for all temperatures M291 P"Bed temperature at setpoint. Please wait 5 minutes for stabilization, Z indicates countdown." R"Hotmesh" S0 T10 ; Start countdown - use Z as indicator while iterations <=9 ; Perform 10 passes G4 S30 ; Wait 30 seconds G1 Z-15 ; Move Z 15mm down G90 ; Set to Absolute Positioning M291 P"Performing homing, gantry alignment, and mesh probing. Please wait." R"Hotmesh" S0 T10 G32 ; Home and Level gantry M400 ; Clear queue G29 ; Perfrom bed mesh M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed M291 P"Hotmesh complete. Hotend and Heatbed are turned off. Performing final homing routine. Please wait." R"Hotmesh" S0 T10 G28 ; Home -

Alternative setup to load bedmesh from the system's set filament type directory, and if start.g fails load the file (because it doesn't exist) it will create one.

Alternative Hotmesh.g:

This saves the heightmap to the system's set filament type directory (0:/filaments/PETG/heightmap.csv); 0:/macros/hotmesh.g ; Called to perform automatic heated bedmesh compensation ; Alternative Hotmesh.g - This saves the heightmap to the system's set filament's type directory (0:/filaments/PETG/heightmap.csv) if state.status = "processing" ; Printer is currently printing! M99 ; Abort this macro T0 ; Ensure tool is selected M703 ; Heat bed to set temp based off current system filament type M104 S-273 ; Turn off hotend M106 S0 ; Turn part cooling blower off if it is on M291 P{"Performing bed heatup per " ^ move.extruders[0].filament ^ " profile. This process will take approximately 6 minutes."} R"Hotmesh" S0 T10 G28 ; Home G1 X100 Y100 ; Place nozzle center of bed ; Give 5 minutes for stabilization G91 ; Set to Rel Positioning while iterations <=9 ; Perform 10 passes G1 Z15 F300 ; Move Z 15mm up G4 S0.5 ; Wait .5 seconds M116 ; Wait for all temperatures M291 P"Bed temperature at setpoint. Please wait 5 minutes for stabilization, Z indicates countdown." R"Hotmesh" S0 T10 ; Start countdown - use Z as indicator while iterations <=9 ; Perform 10 passes G4 S30 ; Wait 30 seconds G1 Z-15 F300 ; Move Z 15mm down G90 ; Set to Absolute Positioning M291 P"Performing homing, gantry alignment, and mesh probing. Please wait." R"Hotmesh" S0 T10 G32 ; Home and Level gantry M400 ; Clear queue G29 ; Perfrom bed mesh G29 S3 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Save heightmap.csv to filament type's directory M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed M291 P"Hotmesh complete. Hotend and Heatbed are turned off. Performing final homing routine. Please wait." R"Hotmesh" S0 T10 G28 ; Home M18 ; Free allAlternative Start.g:

Alternative Start.g - This loads the heightmap from the system's set filament type directory (0:/filaments/PETG/heightmap.csv), if the heightmap does not exist, create one, and then save in the filament's directory.; 0:/sys/start.g ; Executed before each print - BEFORE ANY SLICER CODE IS RAN ; Alternative Start.g - This loads the heightmap from the system's set filament ; type directory (0:/filaments/PETG/heightmap.csv), if the heightmap does not ; exist, create one, and then save in the filament's directory. T0 ; Ensure tool is selected ;M280 P0 S160 ; BLTouch, alarm release ;G4 P100 ; BLTouch, delay for the release command M572 D0 S0.0 ; clear pressure advance M220 S100 ; Set speed factor back to 100% in case it was changed M221 S100 ; Set extrusion factor back to 100% in case it was changed M290 R0 S0 ; Clear babystepping M106 S0 ; Turn part cooling blower off if it is on M703 ; Execute loaded filament's config.g G28 ; Home all ;G1 Z5 X100 Y100 ; [PINDA] Place nozzle center of bed, 5mm up G1 Z160 F300 ; [BLTouch] Last chance to check nozzle cleanliness M300 S4000 P100 G4 P200 M300 S4000 P100 ; Give a double beep M116 ; wait for all temperatures M300 S4000 P100 ; Give a single beep ; [BLTouch] Start countdown - use Z as indicator G91 ; [BLTouch] Set to Relative Positioning while iterations <=9 ; [BLTouch] Perform 10 passes G4 S12 ; [BLTouch] Wait 12 seconds G1 Z-15 F300 ; [BLTouch] Move Z 15mm down G90 ; [BLTouch] Set to Absolute Positioning ;G4 S120 ; [PINDA] wait additional 2 minutes for the bed to stabilize G32 ; Level bed G29 S1 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Load bed mesh for the system's set filament type if result > 1 ; If file doesn't exist, perform mesh and save G29 ; Perform mesh now G29 S3 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Save heightmap.csv to filament type's directory M400 ; Finish all current moves / clear the buffer G90 ; Absolute Positioning M83 ; Extruder relative mode M98 P"0:/sys/current-sense-normal.g" ; Ensure that motor currents and sense are set for printing G1 X0 Y0 Z2 ; Final position before slicer's temp is reached and primeline is printed. ; The primeline macro is executed by the slicer gcode to enable direct printing ; of the primeline at the objects temp and to immediately print the object ; following primeline completion. ; Slicer generated gcode takes it away from here -

Latest README: README.pdf

Latest sd-card dump: README above contains dump.

Latest wiring guide: Duet2.pdf

Archive file containing the full set of sd-card files, wiring guide, readme, and ideaMaker example profile set.The next meaningful revision of my files will most likely occur once variables are enabled within the gcode macros.

If you find any issues or have any suggestions please let me know so I can take the appropriate actions and make this a better guide/code for the public.

Many thanks Duet forum people!

Cheers,

Kolbi -

Thanks for the excellent reference examples.

Also just a heads up it looks like the forum software or copy paste error is inserting some random

{1}to your blocks. -

@Phaedrux Thanks much!

I saw the {1} and tried to get rid of them but for some reason, it didn't work.

I did attach my dump-list.pdf so people could view it there also - I keep this one updated too.I'll give it a shot once I get some time this evening. Do you know what causes them?

Cheers,

Kolbi -

@Kolbi said in Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11:

Do you know what causes them?

They seem to show up on line breaks within the code blocks for some reason. It's a forum issue.

-

@Phaedrux said in Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11:

show up on line breaks within the code blocks

Ah! Just add a space after a line break and that gets rid of it.

-

Good to know!

-

@Phaedrux said in Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11:

They seem to show up on line breaks within the code blocks for some reason. It's a forum issue.

not for all types of code interestingly enough, but haven't experimented with the complete list of language highlighting.

-

Updated stop.g, focused on getting rid of spider web / hair like stringing from nozzle while leaving nothing on nozzle.

; 0:/sys/stop.g ; called when M0 (Stop) is run (e.g. when a print from SD card is cancelled) M83 ; Set extruder to relative mode M106 S255 ; Turn fan fully on M572 D0 S0.0 ; clear pressure advance M220 S100 ; Set speed factor back to 100% in case it was changed M221 S100 ; Set extrusion factor back to 100% in case it was changed G1 E-2 ; Retract 2mm M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed G1 F1000.0 ; Set feed rate M98 P"current-sense-homing.g" ; Adjust current and sensitivity for homing routines ; Let cool and wiggle for bit to reduce end stringing M300 S4000 P100 G4 P200 M300 S4000 P100 ; Give a double beep G91 ; Set to Relative Positioning G1 Z2 F400 ; Move Z up 3mm ; Start countdown - use X/Y as indicators of counting while iterations <=9 ; Perform 10 passes G4 S6 ; Wait 6 seconds G1 X1 Y1 F1000 ; Wiggle +1mm G4 S6 ; Wait 6 seconds G1 Z0.5 X-1 Y-1 F1000 ; Wiggle -1mm, Z +0.5 G90 ; Set to Absolute Positioning G1 X220 Y205 Z205 F1000 ; Place nozzle to the right side, build plate to front, Z at top M400 ; Clear queue M107 ; Turn off fan M18 YXE ; Unlock X, Y, and E axis ; Play a triumphant tune to celebrate a successful print. G4 S1 M300 P250 S750 G4 P251 M300 P200 S1250 G4 P201 M300 P250 S750 G4 P251 M300 P200 S1250 G4 P201 M300 P250 S2500 G4 P251 M300 P150 S2000 G4 P151 M300 P150 S2500 G4 P151 M300 P350 S3700 G4 P351 M400 -

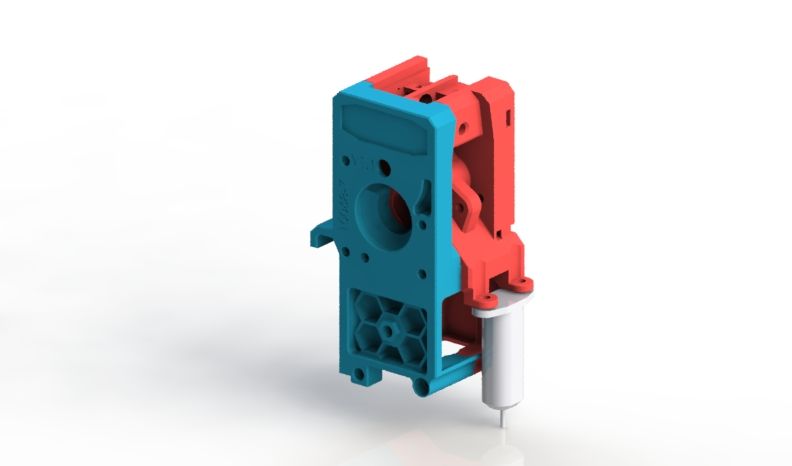

Attached modified BMGm-BLTouch.

Offsets at X22.8, Y3.8, Z1.32.10068-6 Prusa Housing Rear MK3s MosquitoV1.4.STL 10068-7 Prusa Housing Front MK3s MosquitoV1.4.STL

-

Forgot the bltouch wire cover.

bltouch-wirecover.STL*The front and back parts require threaded inserts.

-

undefined jdebuhr referenced this topic

undefined jdebuhr referenced this topic

-

undefined T3P3Tony unpinned this topic

undefined T3P3Tony unpinned this topic

-

Hello @Kolbi do you have an enclosure for Duet wifi that mount to the printer ? I’d love to have an STL if you mind sharing

-

@e4d Sorry, It's been a while and I don't have that on my latest laptop. I'll give a search on my home server when I get a chance to see if I may have backed it up.

But, give a look at the caribou github - variants from duet 2 and 3mini exist.

https://github.com/Caribou3d/CaribouCartesian/tree/master/STL/01_full-kits/Frame/DuetHope that helps!