Best bed levelling system?

-

@mrehorstdmd

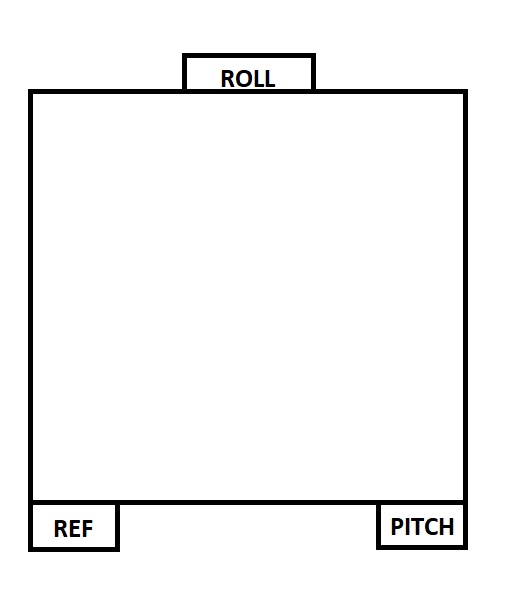

Someting like this?

Do you think the d-bot structure will be rigid enough for the extra weight of the bed?

Just for talking, what problem do you find in using a single plate made of glass ( plate and printing surface at same time), a thick one , maybe 10 mm , with holes like your plate. the problem could be the weakness and low thermal conductibility so longer time for reach the temperature , but other then that?

Just thinking I have a lot of problem finding small peace of cast aluminium in Italy.

Ideally what planar tolerance is desirable?Other question , , what about inox , if weight isn't a problem , which has a lower thermal dilatation coefficient ?

thx

A. -

@claustro said in Best bed levelling system?:

el are you talking about 3 indipendent motors for Z axis?

can you give me more info regarding your prYes 3 independent motors. In the config you setup where the 3 ballscrews are located in X/Y and then you make a bed file that probes as close to the motors as possible. Once 3x probe points are done it calculates how much to compensate on each screw and then it levels. On the video below it only corrects 0.190mm error so it's not easy to see the correction after probing but it works really quick and simple.

-

@claustro Your diagram is good.

You don't want to attach a heater to glass because the heaters don't heat evenly by themselves and glass is a thermal insulator and will not spread the heat well. Also, glass can break. You really should mount the heater on a thermal conductor like aluminum (cheapest, readily available material). If you want to put glass on the aluminum it's OK if the aluminum is flat or the glass is thin enough to conform to an unflat aluminum surface. If you put thick glass on an unflat aluminum surface, the heating will be uneven and may have problems with prints sticking.

The D-bot's strength will depend on how you built it.

Planar tolerance that is a small fraction of print first layer thickness is best, but if it isn't very flat, mesh compensation can make it usable.

-

I have a modified Dbot. You can see my solution to the Z axis deficiencies in the link in my signature.

In summary, it is 3 point adjustment of aluminum plate on a solid bed platform, V wheels at all 4 vertical corners with a cross brace on the front of the bed frame, and 3 lead screws synced to 1 motor with a belt. To level the bed I use manual bed level assistant to help me adjust the bed screws. The platform itself must be aligned very carefully to begin with, but once aligned it stays stable for me. Then I use mesh bed compensation to adjust for the bed surface (one corner of my bed has a slight curve. If your plate is flat, this isn't needed.)

There are many ways to go about this. It's a trade off. After seeing the railcore II this weekend at MRRF using the 3 independent lead screws to do automatic leveling I can confirm that when designed correctly to allow for some flex it can work very very well. On the flip side, if you have a solid platform and a single motor, you can get great results without it. It's nice to have options.

-

Hi,

This is what I have been told to use, on several occasions, for bed plates:

https://www.midweststeelsupply.com/store/castaluminumplateatp5

It's cast rather than rolled and is supposed to be more uniform.

Frederick

-

@claustro said in Best bed levelling system?:

Worth change from printed bed support to aluminum one?

Absolutely. There are aluminum versions of several of the basic printed dbot frame parts. Replace as many of the printed parts as you can.

-

I might try a three lead screw setup.

Where did you find such a long belt?

Thanks.

Frederick

-

@fcwilt I'm in Canada, so I got it from MakerParts.ca

https://makerparts.ca/products/102mm-long-6mm-wide-gt2-endless-belt-loop?variant=37138162511

They carry a lot of the OpenBuilds parts and other various printer parts on the higher end of the quality spectrum. I originally had a loop belt and pulleys from aliexpress, but the belt was stretchy and the pulleys out of round and I had some Z banding issues, but after switching to the parts from MakerParts I had no more issues.

-

@phaedrux said in Best bed levelling system?:

@fcwilt I'm in Canada, so I got it from MakerParts.ca

https://makerparts.ca/products/102mm-long-6mm-wide-gt2-endless-belt-loop?variant=37138162511

They carry a lot of the OpenBuilds parts and other various printer parts on the higher end of the quality spectrum. I originally had a loop belt and pulleys from aliexpress, but the belt was stretchy and the pulleys out of round and I had some Z banding issues, but after switching to the parts from MakerParts I had no more issues.

Thanks.

I think I am seeing the same thing. I get much of my stuff off of Amazon but I think most is low cost import stuff.

Frederick

-

Thank you all for such great suggestions.

I am still not sure which way to go.I have a no cantilever 2 lead screw single motors setup , changing to 3?

3 lead screws with one motor: pro lead screw always in sync con need manual adjustment

3 lead screws with independent motor pro automatic leveling of the plane cons a little bit more expensive , need software setup , risk of out of sync motors?

with this setup is bed leveling system still needed or the bed plate can be mounted fixed on the frame? Is it possible , and make it sense, combine mrehorstdmd bed leveling system with 3 motors lead screws setup?

I already own the extra Z motors so costs isn't a variable in this decision.These are some photos of my printer take a look , any suggestion is appreciated!

https://www.dropbox.com/sh/7bvnlctmiqushv1/AAB_oR3lea8S2ZBIfeM5EsyUa?dl=0Other question for D-bot owners.

I have 3 wheels Z guide, is it worth converting y axis also to 3 wheels, I read mixed experience about it.@minim can you tell some more of your setup do you have some photos for taking inspiration:-).

Thank you all

A. -

@claustro said in Best bed levelling system?:

3 lead screws with one motor: pro lead screw always in sync con need manual adjustment

Another pro is that if everything is built well enough, you don't need a Z probe. But I would want a Z probe anyway, to set an accurate Z=0 position before a print, to help me adjust the levelling screws, to generate a height map to check that the bed and printing plane are flat, and to make corrections if I didn't get everything perfect..

3 lead screws with independent motor pro automatic leveling of the plane cons a little bit more expensive , need software setup , risk of out of sync motors?

The motors may get out of sync when you power them down, so you need to run the auto levelling each time you power up, perhaps as part of the Z homing procedure.

with this setup is bed leveling system still needed or the bed plate can be mounted fixed on the frame?

It can be fixed on the frame, if you build it accurately. For example, you don't want the leadscrews to have to force a tilt on the bed because you didn't get the XY axis level.

In theory you could also have the bed fixed on the frame if you use a single Z motor, by making provision to adjust the belt lengths between the 3 pulleys. This could be done by having 3 adjustable idlers (instead of just 1 which I think you would normally have so that you can adjust the belt tension). But this is outside my experience.

I already own the extra Z motors so costs isn't a variable in this decision.

Don't forget that you need 6 stepper drivers for this arrangement, so there is also the cost of a DueX2 or DueX5 unless you already need one to do multi extrusion.

-

@claustro Only you can decide.

I think the arguments that I and others have put forward for using 3 screws are strong and valid.

One thing you might have overlooked is that with 3 independent motors, whenever power is applied, they will get out of sync by up to 4 full steps. So if you decide to go down that route, then you will have level the bed every time you apply power to the printer.

So with a single motor and continuous belt driving 3 screws, then levelling has to be done manually but once set (and if the printer is built well) then it won't need doing again for months or even years. With independent motors then levelling is easier to accomplish but you have to do it every time power is applied to the printer.

I know which I prefer but I'm not you..........

-

@claustro said in Best bed levelling system?:

@minim can you tell some more of your setup do you have some photos for taking inspiration:-).

There is not much more to show than what's in the video. It's a core xy that I designed myself and I use HGR15 rails for the Y axis and HGR12 for X axis. The Z axis has 3x 1204 ballscrews each mounted close to a HGR15 rail that keeps it steady. The cables are still a mess since I'm not done with it yet and I'm trying different solutions to the hotend still before I decide on what I will go with. Also I don't have any home switches so it's homed with stall detection for now and it's been doing good (Z axis has a bltouch tho).

-

Ok .

@dc42

I already own a probe and I like all the info it can give me thanks of your great firmware

I m planing to go to the simplest route first.

So I 'll add a lead screw and and an aluminum casted plate ( if I evere will be albe to find it )

)

I'll stick with one motor solution , so the only extra expense will be lead screw and a new longer belt and new pulley.

If everything will be ok I'wil stick with it , if not I can simply add 2 Z motors and a duet expansion board.I have 8mm chinese lead screw, would be a good idea go for 10mm ones?

Can someone suggest me a trusted shop buy good quality stuff?

Thank you

Andrea -

@claustro said in Best bed levelling system?:

Other question for D-bot owners.

I have 3 wheels Z guide, is it worth converting y axis also to 3 wheels, I read mixed experience about it.I'm using 3 wheel carriages with screw tensioners on X Y and Z and it makes it very easy to tension the wheels.

-

@claustro said in Best bed levelling system?:

I have 8mm chinese lead screw, would be a good idea go for 10mm ones?

8mm should be sufficient. You want the lead screws to provide up and down motion. It's up to the linear guide system to keep it in place in X and Y.

Can someone suggest me a trusted shop buy good quality stuff?

-

for mechanical parts check your local cnc supplier.

for germany this shop sell high quality equipment (and is very expensive)

https://www.dold-mechatronik.de/Mechanics -

@deckingman said in Best bed levelling system?:

@claustro said in Best bed levelling system?:

.................. I am afraid about aluminum bed for 3 reasons cost, availability and thermal reaction.................

Aluminium tooling plate is the best solution because the bed needs to be flat, and it needs to be stiff enough, and it needs to have good thermal conductivity. This question gets raised with monotonous regularity.

Aluminum doesnt remain flat though. Glass is preferable.

-

@kungpaoshizi said in Best bed levelling system?:

@deckingman said in Best bed levelling system?:

@claustro said in Best bed levelling system?:

.................. I am afraid about aluminum bed for 3 reasons cost, availability and thermal reaction.................

Aluminium tooling plate is the best solution because the bed needs to be flat, and it needs to be stiff enough, and it needs to have good thermal conductivity. This question gets raised with monotonous regularity.

Aluminum doesnt remain flat though. Glass is preferable.

Of course aluminium tooling plate remains flat - why do you say it doesn't? For reasons that I and others have stated, you really don't want to fix a heater directly to glass because local hot spots will cause it to crack. Glass on top of aluminium is perfectly acceptable (it is what I use in fact), as are various other surfaces like PEI but glass as an alternative to aluminium is completely unacceptable.

-

@kungpaoshizi said in Best bed levelling system?:

Aluminum doesn't remain flat though

There's a very big difference between a thin piece of rolled or sheared aluminum and a thick piece of cast and milled tooling plate. Tooling plate is cast so it doesn't have the same internal stresses and it is milled flat afterwards. It should heat and expand quite evenly and with a proper mount would never change shape or expand noticeably in Z.

A thin piece of rolled or sheared aluminum on the other hand would behave like a bag of snakes. So you're right there.