Delta Print Skewed

-

What's the print diameter defined in your slicer? I know that inn slic3r, if the model goes beyond the defined diameter, it will not print outside that, but cut the model off. What happens at the actual edge is probably a bit undefined, but might lead to weird printing artifacts.

-

It's a 300mm diameter bed.

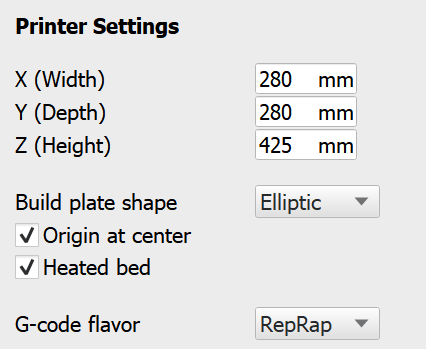

Cura

Simplify3D has the following

-

To take the slicer out of the equation use the DWC "jog" buttons to determine if the X and Y movements are correct.

Position to X=0 and Y=0.

Then start stepping to, say, 50, 100 and 140 measuring each position with a good mm scale to see if the position is correct.

Do this for both X and Y, one axis at a time.

Frederick

-

@fcwilt thanks for the suggestion, but already tried that and movement is correct in both axis. It also moves to all the correct positions defined in bed.g when doing auto calibration. You can see the little dots of filament around the edges of the bed in the photo above.

-

@richardmckenna said in Delta Print Skewed:

@fcwilt thanks for the suggestion, but already tried that and movement is correct in both axis. It also moves to all the correct positions defined in bed.g when doing auto calibration. You can see the little dots of filament around the edges of the bed in the photo above.

OK that rules that issue out.

Try including a skirt while printing. I would not be surprised if you are having bed adhesion issues as printing moves away from center.

What does your height map look like?

-

@fcwilt I don't think it is that. I have tried with a skirt/brim the nozzle actually moves in that squashed shape rather than the 20x20 square.

Here is my height map

-

@richardmckenna Your height map looks good.

When I was trying to fine tune my deltas I created models (using OpenSCAD) of simple thin discs of different diameters (50, 100, 150, 200, etc). The larger discs revealed problems with adhesion.

It took some tweaking to get good results. A first layer of 150% and a first layer speed of 25% worked well. I always include a skirt as it quickly shows if something is not right.

Frederick

-

@fcwilt thanks for the ideas. It’s just doing a small print (where it works in the middle) when that has finished I will try the concentric rings to see what that shows.

I always tend to use a skirt as I find it helps highlight adhesion issues, while priming the nozzle. I just didn’t include it in the test above as I wanted to see exactly what it did with just the 20x20 square.

-

What B parameter did you specify in your M665 command in config.g? The firmware won't allow you to move the nozzle outside that radius while printing.

-

@dc42

M665 R200 L360.22 B140 H457So the square is well within the 280mm diameter. However that got me thinking. So I've had a look at what was produced for the config-override.g file and that has the following in it.

; Delta parameters

M665 L360.220 R196.872 H449.085 B100.0 X0.166 Y0.098 Z0.000

M666 X0.718 Y-1.185 Z0.467 A0.00 B0.00Why would B be 100 in the config-override.g file?

-

@richardmckenna said in Delta Print Skewed:

Why would B be 100 in the config-override.g file?

Because you had it set to 100 the first time you used M500 to save the parameters.

-

@dc42 I re-tensioned the belts this evening to make sure that wasn't causing the problem and ran G32 3 times, then used M500 to save the parameters.

I'm guessing M500 does not update the B parameter in the override file?

-

Perfect I now get full build plate printing. It says not to but I just edited the override file with the correct value and used M501 to read the new values.

Thanks all for your help. Much appreciated.

-

@richardmckenna said in Delta Print Skewed:

Perfect I now get full build plate printing. It says not to but I just edited the override file with the correct value and used M501 to read the new values.

Thanks all for your help. Much appreciated.

Glad to hear you got it working.

One thing I don't understand though. When I suggested using a scale to verify movement in the X and Y axes you said that you had done that.

It shouldn't have been possible to reach the min/max positions if the settings in config-override.g were wrong.

Did something change config-override.g AFTER you made those measurements?

Frederick

-

@fcwilt not that I know of. If the B parameter in config-override.g was set the first time I ran M500 and not updated each time I’ve run M500 since then it has been like that for a couple of weeks.

Yesterday when it wouldn’t print out at at the edge the first thing I did was check the movement in the axis was correct checking the jog movement with the expected distance.

What I don’t understand is why the firmware let me manually jog the print head out to the edge and also how I was able to probe the outer points for auto calibration.

-

@richardmckenna said in Delta Print Skewed:

@fcwilt not that I know of. If the B parameter in config-override.g was set the first time I ran M500 and not updated each time I’ve run M500 since then it has been like that for a couple of weeks.

Yesterday when it wouldn’t print out at at the edge the first thing I did was check the movement in the axis was correct checking the jog movement with the expected distance.

What I don’t understand is why the firmware let me manually jog the print head out to the edge and also how I was able to probe the outer points for auto calibration.

Every time you started the Duet after running M500 that first time, the B100 in M665 in config-override.g will have overridden the one in M665 in config.g. So when you changed M665 in config.g to B150, it had no effect.

When bed probing using the G30 commands in bed.g, movement limits are not applied. This allows you to probe outside the normal print area, for example between the towers and outside the usual print radius, for better calibration accuracy. But the M665 B parameter will prevent you from doing manual moves outside the bed radius, unless you send M564 S0 to override the limits.

-

@dc42 ah thanks for the explanation. That makes total sense and is obvious looking at it now.

This is my second diy printer build and my first delta so still getting used to the quirks of deltas and tuning them. My CoreXY was a bit more obvious to configure.

I must say though the Auto Calibration combined with the Smart Effector is just genius and a life saver. Would be interesting to see if the Smart Effector style bed probing could be adapted to Cartesian/CoreXY printers. Maybe a rectangular PCB attached to the carriage.