Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?

-

@mindbender9 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

So if the bed is lopsided, then something is not aligned right on my delta? Or the three pillars are not set well? How would I be able to check this, because everything seems rigid?

Are you sure the bed is lopsided? If you have an engineer's or carpenters's square, use it to check whether the bed is at right angles to the towers.

I still cannot print a base layer - only half is possible and the nozzle drags along the bed which prevents filament from being laid down.

That may simply mean that your endstop corrections are not set correctly. Calibration (G32) will fix that.

-

@dc42 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Are you sure the bed is lopsided? If you have an engineer's or carpenters's square, use it to check whether the bed is at right angles to the towers.

Am I supposed to add shims under the bed? There doesn't appear to be a way to raise/lower the bed mechanically with the Anycubic Kossel Plus. It's just lopsided on one of the three sides.

I still cannot print a base layer - only half is possible and the nozzle drags along the bed which prevents filament from being laid down.

That may simply mean that your endstop corrections are not set correctly. Calibration (G32) will fix that.

I performed a manual calibration (G32) and the nozzle did a HARD nose bury into the bed when a test print was attempted. It tore up the blue painters tape that I had on the bed and the test 1mm circle print was a mess. Half of it was missing (the side where the tape was pulled up) and the other half was stringy and a mess.

This is not working.

-

I don't have a way of acquiring those right angle guides at the moment.

I loosened and readjusted the three pillars as best as I could. The nozzle still buries itself into the bed hard and tears up the surface on half of the print, then releases filament 1-2mm above the bed on the other half.

And this happens after I do a manual calibration (G32).

Could this miserable delta hardware be so screwed up that this kind of results will repeat over and over?

-

If you can't get a carpenter's square, use anything that you are confident is 90 degrees, and is about the right size.

A heavy card, a plastic cover, your mobile, something.With the towers reasonably square, and the bed sitting in consistent clips or supports of some sort, there is almost no way for it to be off that much over a span the size of the circles in your photo. Something else is wrong.

By the way, when it digs in like that, TURN IT OFF. Don't let it continue to tear tape, or the plastic bed, or whatever.

Now, back to basics:

Are all six rods the same length? To within 1/10 of a MM? I've seen Anycubics with rods that vary by as much as 1mm across the six. This will cause all kinds of problems.

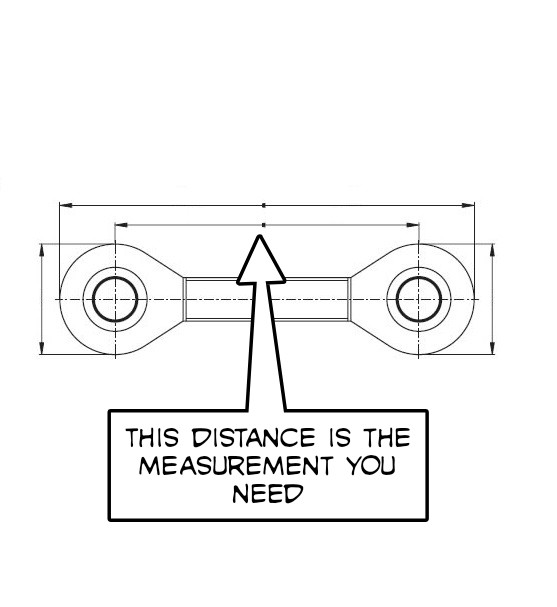

Is everything at all six attach points to the effector the same? Like this:

Is everything at all three carriages the same? Etc, etc.

Can we please re-verify what is in your latest "config_override.g", after you've done your latest series of G32 and M500? Please post the whole thing.

-

Oh, and can you please post a video shot in such a way we can see the carriages, the home switches, and the bed, while the printer does a full G32 sequence?

Post to youtube or vimeo or something, and link here.

-

Here is my config_override.g:

; This is a system-generated file - do not edit ; Delta parameters M665 L271.000 R152.869 H301.792 B85.0 X6.799 Y4.280 Z0.000 M666 X2.286 Y-0.607 Z-1.679 A0.00 B0.00 ; Heater model parameters M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1 M307 H1 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0I'll have to work on making the video, but I'll measure the arm lengths soon.

Thank you.

-

Hi mindbender, i'm currently in a similar situation as you so i've been following this thread for info. I have a new anycubic kossel plus that i just upgraded to metal corners and duet control. I just noticed that you have your rod lengths set to 271mm. If you got your kossel plus in the last 7 or so months, then you most likely have the "upgraded" rods which are now 268mm in length.

Also, do yourself a favor and throw away those mounts that the bed sits on, they don't hold the bed at all and allow for bed tilt if they aren't perfectly level themselves. Secure the bed directly to the horizontal beams if possible. The heated bed has 3 holes spaced equally around the perimeter that take M3 bolts. Mine sits on top of standoffs and I modified the bed so that the bolt heads sit below the surface. If you don't want to make that kind of mod, then you can decrease your bed size to avoid running the nozzle over the bolt heads.

-

Juice may have hit part of it, if the rods are different than specified. Do check that... and, normally, this makes a very symmetric "dome" or "dip", not a "tilt". So lets keep measuring some other things as well.

Also, his tips on the bed look great!!

M666 looks reasonable. These are tower angular offsets, and almost all printers will have some small corrections here.

However, the M665 X Y Z offsets look quite large. These are the "uneveness" in the limit switches. It certainly possible these accurately reflect what's happening in the physical printer, because Anycubic Kossels have a couple of things that can throw these off mechanically. Still, it would be better if they were more even. Therefore:

-

Loosen the top plastic things on which the endstops are mounted, and use some small object as a "spacer" to get them as precisely as reasonable possible from the top frame. The key being to make the even.

-

Use something small as a spacer to set the screws in the top of the carriages, so they are all the same length (height). Again, shooting for even/consistent.

-

Run a G32 (maybe a couple) and an M500, and post the override file again.

We'll keep plugging away.

-

-

Thanks for the tips. If I measure the arms from end to end (including the chrome eyeholes at each end), all arms measure to the same 279mm. Does that seem right?

I’ll have to get the M3 bolts to address the bed angle. I think you’re 100% on the money with those horrible bed mounts. Will advise. Thanks again.

-

Thank you for the tips regarding the endstops. I’ll measure and space them evenly - will report back. Thanks.

-

I just noticed something when trying to screw the arms back to the slide arms at the top (these are what connect with the end stops).

It looks like three of the arms have M3? bolts that do not tighten back on the slide arms - they just spin and spin but don’t tighten. Is this a sign that the slide arms are defective?

-

Hi, there is a floating 'nut' located inside of the slider. That nut has likely slipped out. I had that same exact problem. If your luck is holding it may not have actually fallen out. But you'll likely have to disassemble the carriage assy, use tweezer to reposition the nut while you thread the bolt into it, provided its still inside. On one of my sliders, the plastic cracked and I was forced to glue it together using a clamp.

Your rod-end bearings appear to be superior quality compared to what AC sold me.

good luck.

3mm

-

@mindbender9 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Thanks for the tips. If I measure the arms from end to end (including the chrome eyeholes at each end), all arms measure to the same 279mm. Does that seem right?

I’ll have to get the M3 bolts to address the bed angle. I think you’re 100% on the money with those horrible bed mounts. Will advise. Thanks again.

The measurement you need is from center to center of the eye holes. I haven't measured all of mine but i doubt they are all exactly 268mm since my bed still calibrates to a slight dish.

-

Juice's diagram is perfect. Hole center to hole center.

Mindbender9: If they are indeed anything but 271 (your current M665 L setting), that can cause numerous problems. Measure hole-hole carefully, and if they are not 271:

-

Put the actual measure in M665 in config.g

-

Delete config_override.g entirely.

-

Reboot (or power cycle) the printer

-

Re-run M32 a couple of times, and then M500

Post your config_override.g ...

Seems like we are getting closer.

-

-

Measuring Eyehole to Eyehole, the arms are 270-271mm in length.

@3mm - You were right on the money regarding the floating nuts. I was able to reattach all of the arms after removing the sliders like you mentioned. Thanks again.

@Danal - I set all three sliders and endstops to the same position equally. One slider arm was slightly off by 1mm compared to the other two, but now they're all evenly set.

I want to recheck the three main pillars again before performing a test calibration. Just to be safe.

Thanks guys for all of the help. Believe me, I am very grateful for all of the tips and direction you're sending my way. I would be (more) lost if you guys weren't jumping in to help.

Much appreciated as always!

-

How did you make the measurement? I need to measure mine more precisely, my bed calibrates to an upward tilt on the Y tower side but i'm pretty sure they are perpendicular.

-

Hi @Juice

If you mean the arms, I disassembled them from the Nozzle/Hot-End and the slider assemblies. Then I measured each using a ruler, and they were all uniform in length.

But I more or less used your diagram (thank you for that) and eyeballed to center position in each eye.

Getting the arms reattached took a little work.

-

Ok thanks mindbender. I just finished measuring mine, i made a jig and measured as best i could with a steel ruler and all but 1 came out to about 266.5mm, not quite the 268 that they are supposed to be. Anycubic QC needs some work. The one arm is longer and fits the jig a fair bit tighter than all the others, it may be .1-.2 mm longer. Does anyone have any suggestions on what i should do in this situation?

-

@juice - How long has it been since you've purchased the AC Kossel? If it's still under warranty, you could pursue getting a replacement part for that single arm.

On second thought, trying to get tech support from Anycubic3D wasn't easy. You might have better luck going through the seller for a replacement part under warranty.

Otherwise, several people have recommended carbon fiber aftermarket arms/ball ends as being one of the best upgrades for a delta printer. When I get my printer to work, I might look at replacement arms as a future purchase.

-

@juice said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Ok thanks mindbender. I just finished measuring mine, i made a jig and measured as best i could with a steel ruler and all but 1 came out to about 266.5mm, not quite the 268 that they are supposed to be. Anycubic QC needs some work. The one arm is longer and fits the jig a fair bit tighter than all the others, it may be .1-.2 mm longer. Does anyone have any suggestions on what i should do in this situation?

Be sure and set M665 L to 266.5, even if it seems to make things worse at first; getting that right is foundational to getting all the other settings.

With regard to the difference, I wouldn't count on getting anything better from Anycubic. Also, I was getting decent prints with stock arms where one was .9mm longer. So... accept it until you upgrade it... If you can, "pair" the arms as best as possible to a given carriage. Longest two together, etc.