Berd-Air pump configuration notes for Duet users

-

Seriously...check the PWM frequency on the fan port you are using to drive it. Once I bumped the PWM freq up to 20k the temp on the motor dropped like a rock.

-

just to add to this we found that the 12V motors run a lot hotter than the 24V ones also the 12V ones are quite able to take out the Mosfets on the Duet (We had this happen to a friend of mine) on testing we found that the coil resistance on the 12V pumps was quite low and they could possibly draw an inrush current of around 9 amps (Coil resistance measured between 2.7 and 3.2 ohms depending on where in the rotational arc it was). The onboard fan misfit recommended max current is 1.5 amps.

the 24V pumps are also much quieter than the 12V ones and they use 550 series motors not 540 ones (A bit larger they both use the 555 series motors.

So I would suggest if useing 12V systems then def use a external Set board (I used the Power Expander from Reprap.me) and maybe even a separate PSU for them. I swapped mine out to 24V but still kept the power expander for a little bit of additional safety.

Doug

-

Thanks for this!

I've confirmed much improved noise level and less heat running at the higher frequency both on 12V and 24V Berd-Airs.

-

@msquared The PWM had nothing to do with my high temps and high current. I was running it directly from my variable bench power supply at a fixed DC level and it was still overheating. It has stopped doing it now, but it was not related to the PWM frequency. I did run my motor through a break-in and cleaned all the residue out. It has functioned fine since. I have been running the motor at different voltage levels and I know it randomly goes up in current. It may have been due to friction on the sleeve bearings. Its running at around 8.2V at 0.85A, which is very good. It runs very cool and quiet.

-

I'm a bit confused about PWM. I have a Berd-Air pump on fan 0 through an e-switch mosfet.

If I add an F25500 parameter to the M106 I have very little control over fan speed.

If I leave off the F parameter I can vary pump speed from 0 to full speed. It seems that the higher the PWM frequency the less control over fan speed.When you run with a high PWM frequency are you still going through an e-switch?

-

@davea said in Berd-Air pump configuration notes for Duet users:

I'm a bit confused about PWM. I have a Berd-Air pump on fan 0 through an e-switch mosfet.

If I add an F25500 parameter to the M106 I have very little control over fan speed.

If I leave off the F parameter I can vary pump speed from 0 to full speed. It seems that the higher the PWM frequency the less control over fan speed.When you run with a high PWM frequency are you still going through an e-switch?

I was not. I still have my e-switch lying around and I may get a chance to test that later tonight or tomorrow and let you know my results. It is very possible that the e-switch may not respond to high PWM values as well as the pump does directly. If that is the case I have a DC-DC SSR lying around and I may give that a shot to see if it makes a difference.

-

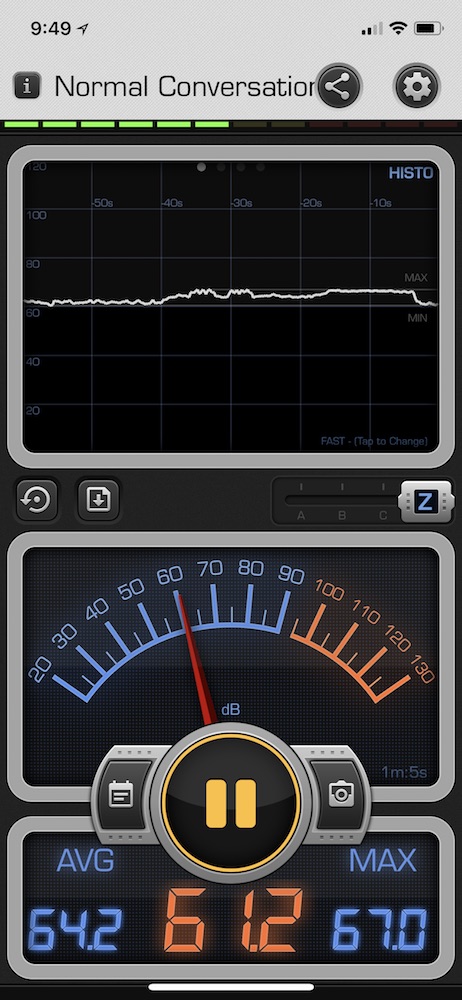

For reference here is a DB monitor of the pump running at very near full speed during a print. This is with the phone about 1" from the pump.

-

Brushless?

-

@klcjr89 said in Berd-Air pump configuration notes for Duet users:

Brushless?

This was actually the brushed version. I will put up something with the brushless in a day or so.

-

@msquared About the flayback diode, your link points to a 1N4007.

I have first tried this one, but it got pretty hot.

After some googling I think the reason is that the diode is just too slow for a high frequency of 25kHz (reverse recovery time of 30us).

I have replaced it by a schottky diode that doesn't get warm.And I would like to know what motors temperatures you observed with the standard pump?

For example, mine has reached about 50°C after a while running at 50%... I don't know if this is good or not... -

If you are using a high PWM frequency (you mentioned 25kHz), please check also that the mosfet isn't getting hot.

-

I've been using:

- The flyback diode provided with the eSwitch kit, sans the rest of the kit.

- The current limiting thermistor DC42 linked to.

I'm getting great results at 25kHz freqency. Prior to changing the frequency, my minimum operating range was about 25%. I'm now able to operate at 20%, and my understanding is the current limiting thermistor is dropping voltage a touch based on the ~30 Ohm resistance I measured when checking my circuit.

-

@dc42 Yeah, the mosfet gets indeed a bit hot.

Hard to measure that tiny thing with a thermometer, but from touching it, I would say roughly around 60°C as I can still touch it for at least a couple of seconds. -

Duet boards with PCB revision 1.02 and later have flyback diodes already included on all fan outputs.

-

So you've set M106 with F25500 as PWM frequency parameter? I've got the same configuration and mofset is well cooled, just asking before changing the configuration.

-

@hergonoway said in Berd-Air pump configuration notes for Duet users:

So you've set M106 with F25500 as PWM frequency parameter? I've got the same configuration and mofset is well cooled, just asking before changing the configuration.

Correct, I'm using F25500 on a 24V (1.03 Duet Wifi) and 12V (0.85 Duet) without issue. I've got a flyback on both. The 0.85 needs the external flyback, but the 1.03 does not. I am not using the eSwitch module.

-

@MSquared Any progress with the brushless pump?

-

Ive got 2 Berd air systems that only need to be at 25% or so to give great part cooling. The sound of air whoosing out is louder than the pump. I am using a brass tube that is 3.75 mm outside diameter with a flattened tip and is positioned to point at the tip of the extruder. This size tube and opening is less restrictive on the pump than the supplied 2.4 mm tube so it runs quieter and supplies more air. Initial positioning of the tube took some trial and error (was quite fiddly as some would say), but once you've got it the results are impressive. My Duets are 0.85 and Wifi 1.0 or 1.01 and both are on 12v. I am not willing to risk running the Berd air pumps on my Duets without the eswitch and hope that no one who does regrets it.

-

Thinking about getting a bigger tube, for the same obvious reasons, air flow. 3,75mm is kind of uncommon did you have to flattened the tube (I think of using 1/8" because 4mm seems to big) ? And did you use a jig to bend the "circle" part?

-

@hergonoway 1/8" is an improvement to the stock tube and is close to 3.75 (3.18). I flattened the tube by stripping a length of #12 AWG stranded and inserting as many wires as possible into one end. I flattened the end with a small hammer and pulled out each wire with pliers afterward. I am not using a circle, only the flattened tip.