Duet 2 v1.02 not responding

-

@droftarts Tractus 3d T650P is my printer

A part of the config.g couldn't be copied (2 reputations or something error)

-

@thomasvanderwal Your Tractus is a delta printer, but your config.g is set up for a Cartesian printer? Do you have an old config that worked?

Otherwise, see https://docs.duet3d.com/User_manual/Machine_configuration/Configuration_linear_delta

Ian

-

@droftarts no, a colleque got this printer from a company. He's gone

I am a educator at a technical school. -

@thomasvanderwal Okay. I think start again with the configuration tool, but this time select "Linear Delta" for Kinematic type. https://configtool.reprapfirmware.org/Configuration#kinematics

Tractus3D have renamed/been taken over by https://nexum3d.com/. You may be able to contact them and get them to send you a standard configuration for your machine. They are a Dutch company based in Amsterdam, i believe.

Ian

-

@thomasvanderwal said in Duet 2 v1.02 not responding:

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.0 running on Duet Ethernet 1.02 or later

Now that you're seeing some progress it may be a good time to update your firmware before you get too far with configuring. 3.0 is quite old now.

If you have access to DWC, you should upload the following zip files one at a time. It will prompt to install the firmware and restart. Then upload the next version, etc.

https://github.com/Duet3D/RepRapFirmware/releases/download/3.0/Duet2and3Firmware-3.0.zip

https://github.com/Duet3D/RepRapFirmware/releases/download/3.3/Duet2and3Firmware-3.3.zip

https://github.com/Duet3D/RepRapFirmware/releases/download/3.5.4/Duet2and3Firmware-3.5.4.zipThe reason for uploading 3.0 again is to ensure all of the required files are present.

-

I'm getting no response from the company. Can a new firmware work with a duet 2 wifi/ethernet?

I made a homedelta.g and a config.g with RepRapfirmware config tool. I selected delta printer and I think made the right choices with the parameters (sensors). But still homing is going bizar. How can I fix this? My rods are 230mm.

At what starting point do I have to position the nozzle? A message G28 0 0 gets a response that axes are not sufficient.

I put this in my config.g: M665 L230 R165 B100 H315 ; set delta radius, diagonal rod length, printable radius and homed height

Maybe this is wrong or my endstops are at another sensor or so? -

@thomasvanderwal we'd need to see your complete config.g and homedelta.g files to help. However, firmware 3.0 is very old now and it would be easier for us to help you if you upgrade to 3.5.4 or 3.6.0-beta.4.

-

@dc42 I upgraded to 3.5.4. I have adjusted the homedelta.g many times. This was my last.

; homedelta.g

; called to home all towers and extra axes

;

; generated by RepRapFirmware Configuration Tool v3.5.10 on Mon Feb 24 2025 14:22:27 GMT+0100 (Midden-Europese standaardtijd); home linear delta

G91 ; relative positioning

G1 H1 X650 Y650 Z650 F3000 ; move all towers to the high end stopping at the endstops

G1 H2 X-3 Y-3 Z-3 ; go down a few mm

G1 H1 X6 Y6 Z6 F250 ; move all towers to the high end once more stopping at the endstops

G1 Z-5 F2000

G90 ; absolute positioning

G1 X0 Y0 F2000 ; move X and Y to the centre -

I got reputations error. So I send the file as attachment

-

@thomasvanderwal said in Duet 2 v1.02 not responding:

@dc42 I upgraded to 3.5.4. I have adjusted the homedelta.g many times. This was my last.

; homedelta.g

; called to home all towers and extra axes

;

; generated by RepRapFirmware Configuration Tool v3.5.10 on Mon Feb 24 2025 14:22:27 GMT+0100 (Midden-Europese standaardtijd); home linear delta

G91 ; relative positioning

G1 H1 X650 Y650 Z650 F3000 ; move all towers to the high end stopping at the endstops

G1 H2 X-3 Y-3 Z-3 ; go down a few mm

G1 H1 X6 Y6 Z6 F250 ; move all towers to the high end once more stopping at the endstops

G1 Z-5 F2000

G90 ; absolute positioning

G1 X0 Y0 F2000 ; move X and Y to the centreSo what happens when you send G28 to home all axis? (which will run the homedelta.g macro)

; Configuration file for RepRapFirmware on Duet 2 WiFi ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.10 on Mon Feb 24 2025 14:22:26 GMT+0100 (Midden-Europese standaardtijd) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"my printer" ; set hostname ; Accessories M575 P1 S0 B57600 ; configure PanelDue support ; Network M552 S1 ; configure WiFi adapter M586 P0 S1 ; configure HTTP ; Smart Drivers M569 P0 S1 D2 ; driver 0 goes forwards (X axis) M569 P1 S1 D2 ; driver 1 goes forwards (Y axis) M569 P2 S1 D2 ; driver 2 goes forwards (Z axis) M569 P3 S1 D2 ; driver 3 goes forwards (extruder 0) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0 Y1 Z2 ; set axis mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M906 X800 Y800 Z800 ; set axis driver currents M92 X80 Y80 Z80 ; configure steps per mm M566 X1200 Y1200 Z1200 ; set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 ; set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 ; set accelerations (mm/s^2) ; Extruders M584 E3 ; set extruder mapping M350 E16 I1 ; configure microstepping with interpolation M906 E1000 ; set extruder driver currents M92 E663 ; configure steps per mm M566 E1200 ; set maximum instantaneous speed changes (mm/min) M203 E3600 ; set maximum speeds (mm/min) M201 E1000 ; set accelerations (mm/s^2) ; Kinematics M665 L230 R165 B100 H315 ; set delta radius, diagonal rod length, printable radius and homed height M208 Z0 S1 ; set minimum Z M666 X0 Y0 Z0 A0 B0 ; endstop adjustments and XY tilt, can be determined using auto calibration as well ; Probes M558 K0 P1 C"zprobe.in" H5 F120 T6000 ; configure analog probe via slot #0 M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved G31 P500 X0 Y0 Z0.7 ; set Z probe trigger value, offset and trigger height ; Endstops M574 X2 P"xstop" S1 ; configure X axis endstop M574 Y2 P"ystop" S1 ; configure Y axis endstop M574 Z2 P"zstop" S1 ; configure Z axis endstop ; Sensors M308 S0 P"bedtemp" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0 M308 S1 P"e0temp" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #1 ; Heaters M950 H0 C"bedheat" T0 ; create heater #0 M143 H0 P0 T0 C0 S140 A0 ; configure heater monitor #0 for heater #0 M307 H0 R2.43 D5.5 E1.35 K0.56 B1 ; configure model of heater #0 M950 H1 C"e0heat" T1 ; create heater #1 M143 H1 P0 T1 C0 S285 A0 ; configure heater monitor #0 for heater #1 M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"fan0" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"fan1" ; create fan #1 M106 P1 S0 B0.1 H1 T45 ; configure fan #1 ; Tools M563 P0 D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C -

@Phaedrux It's going towards me. Then up. Finally it get some kind of stuck en going to make a noise like it's wants to go outside the printer

-

M119 gives the following message: endstops- X not stopped: Y not stopped: Z not stopped, Z probe not stopped

-

@Phaedrux

The endstops work when they are triggered. But I'm now looking for the z-probe -

@dc42 I am getting no where. Which board get I buy that is compatible for my tractus 3d t650P? The Duet 3 ?

-

@thomasvanderwal said in Duet 2 v1.02 not responding:

It's going towards me. Then up. Finally it get some kind of stuck en going to make a noise like it's wants to go outside the printer

Please send

M669and check the response says "Kinematics is Linear delta ...".It sounds like one of the motors is not moving when homing. It should move all three together, and the three carriages should go up towards the endstops. When you flashed the firmware, did you disconnect the stepper drivers? If so, maybe you reconnected the stepper motors incorrectly. It's important that the X tower motor and endstop plug into the X driver (driver 0, but actually the middle driver on the board), and the same with the Y and Z motor and endstop. Can you post a picture of the Duet and wiring? Please also post the output of M122 again.

Also, I think your M665 parameters are not correct. Usually the rod length (L) is about twice the delta radius (R), otherwise the movement of the effector is severely restricted. Yours are:

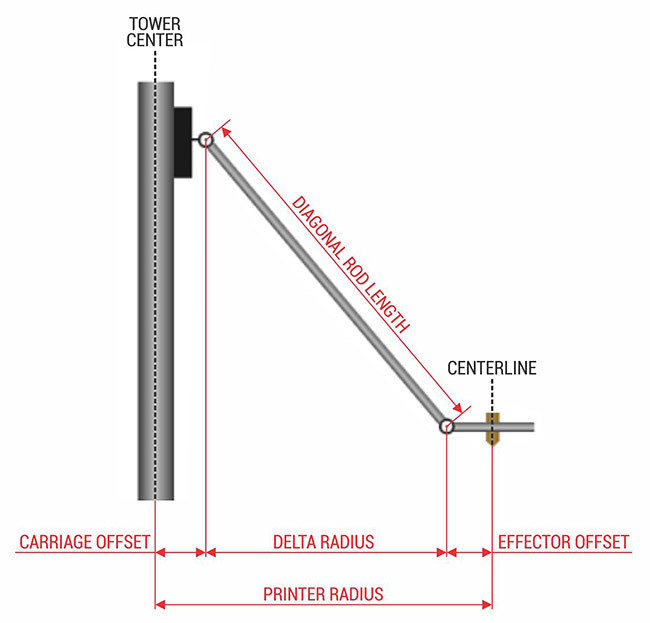

M665 L230 R165 B100 H315See this diagram showing what you need to measure

This doesn't need to be exact, as once everything is working, you can calibrate accurate numbers.

I am getting no where. Which board get I buy that is compatible for my tractus 3d t650P? The Duet 3 ?

I don't think this is a board problem, it's a configuration problem. You would have the same issues if you swapped to another board. Unfortunately there's not much information available about your printer for us to help you, so we will need to recreate the information from what you can tell us.

I did find this pdf manual for the Tractus3D T850/650P, though it's not very helpful in determining the configuration: pro_series.pdf

Ian

-

@droftarts

I heared from someone that I have to downgrade the firmware to <3.

Is it so that duet 2 wifi with a tractus t650P works different with a newer firmware? Codes that response different?

-

@droftarts

Rod length 230mm, print bed radius is 200mm (the circle with tractus 3d on it).

I see no z-probe. Height of printer is also a mistery. How can I measure that? -

@thomasvanderwal said in Duet 2 v1.02 not responding:

I heared from someone that I have to downgrade the firmware to <3.

Is it so that duet 2 wifi with a tractus t650P works different with a newer firmware? Codes that response different?No, you don't need to downgrade. Delta printers work just fine with RRF 3. I have one running on a Duet 2 WiFi, on the latest RRF 3.6.0-beta.4 right next to me. Gcodes to run the printer are the same. Some configuration commands have changed.

You said "a collegue got this printer from a company". Was it supplied with no SD card in the Duet? If there was an SD card, what happened to the configuration files that were on the SD card when you first posted in this thread? Did you delete the SD card? Presumably it was working at some point? If you have the original config.g, please post it.

Rod length 230mm, print bed radius is 200mm (the circle with tractus 3d on it).

These are fine for M665 L and B parameter, but you need the R parameter "delta radius" to be accurate, and I don't think 165mm is correct.

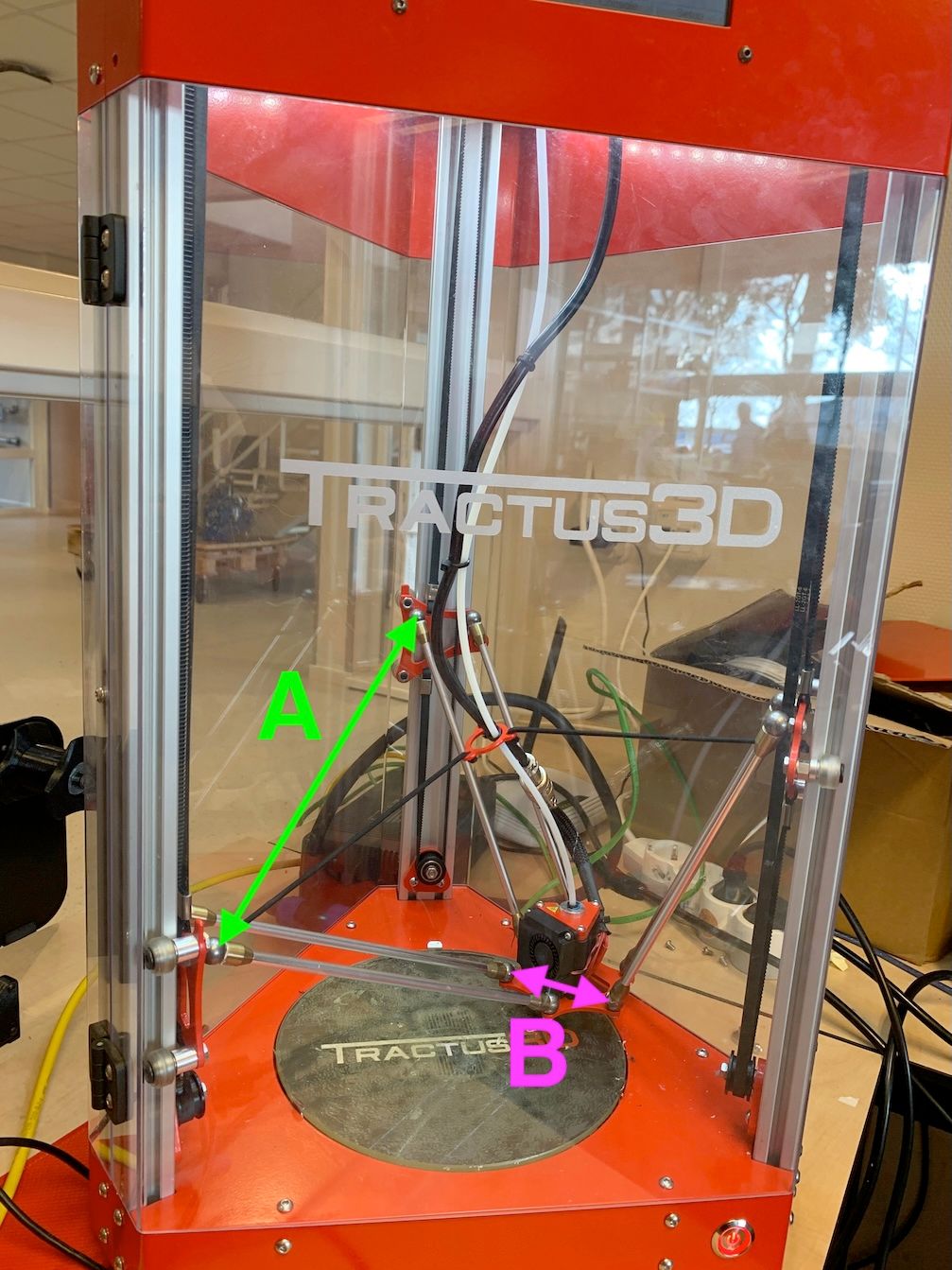

With the nozzle in the centre of the bed so the carriages are level, measure the distance between the centre of the magnetic balls that the rods mount to, as below:

This should measure one side 'A' of the equilateral triangle that defines the carriage positions, and the effector size 'B'. Then use this formula for the circumcircle radius of each, and subtract the effector radius from the printer radius (less carriage offset) to get the delta radius:

(A x √3 / 3 ) - ( B × √3 / 3 )

This should give you a reasonably accurate (+/- a few mm) for the delta radius, for M665 R parameter.

I see no z-probe.

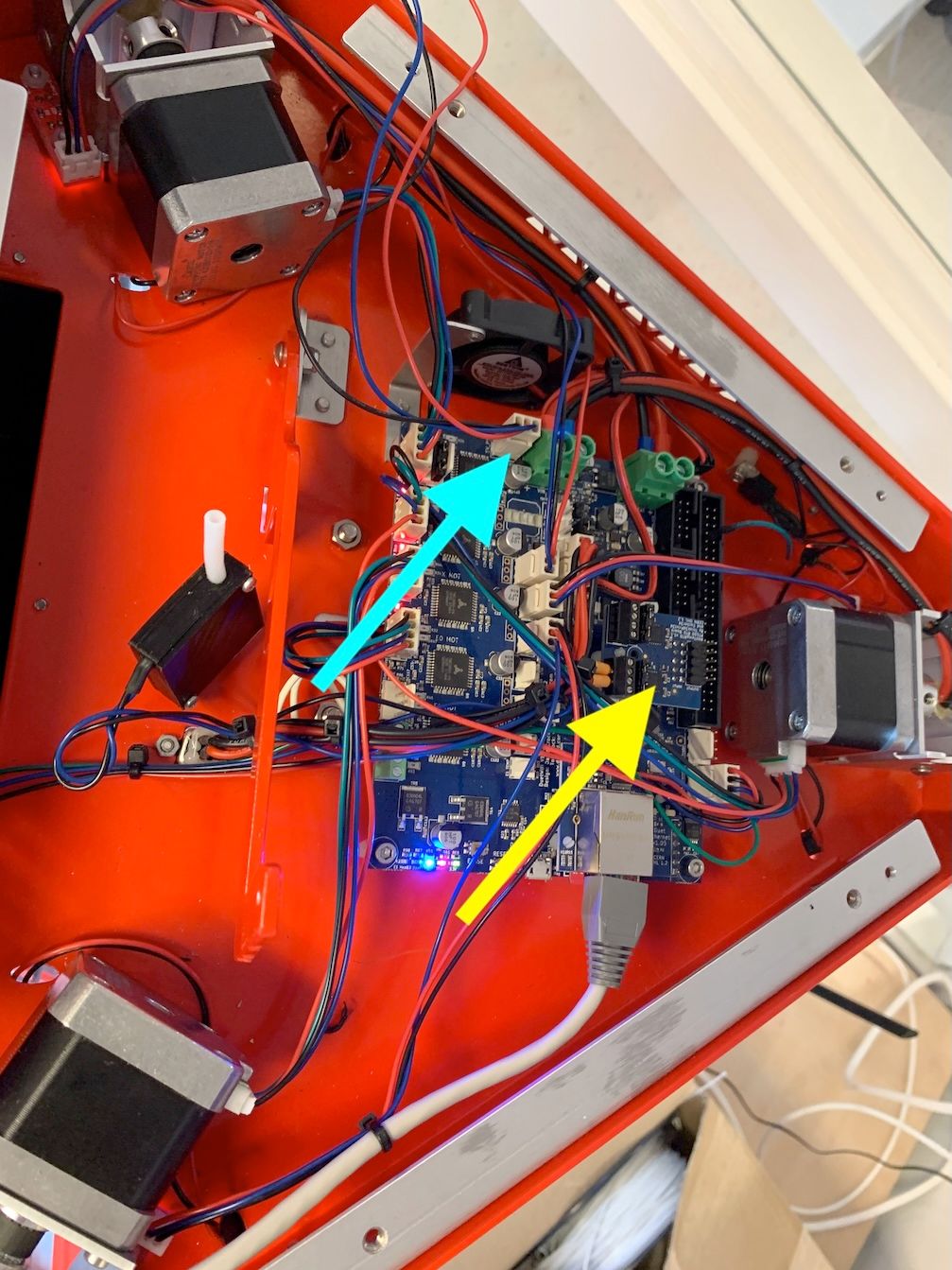

I don't know what the Tractus3D printer uses for a probe. If there's nothing obvious on the toolhead, then most likely it uses a kinematic bed, and the nozzle pushing on the bed breaks a circuit. I think you can remove the bed and look underneath. If so, do that and post a picture. I also think this wire (blue arrow) is incorrect, and may be the probe wire:

It has been connected to the "optional external 5V input and PSU control" connector. I doubt this machine uses an external 5V PSU, so I'd guess this is for something else. Please trace this wire.

Also, it looks like the nozzle temperature is controlled by a PT100 temperature sensor, connected to a temperature daughterboard (yellow arrow). This part of your config.g will need to change:

; Sensors ... M308 S1 P"e0temp" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #1See https://docs.duet3d.com/en/User_manual/Connecting_hardware/Temperature_connecting_PT100

Most likely it will need to beM308 S1 P"spi.cs1" Y"rtd-max31865" ; create sensor number 1 as a PT100 sensor in the first position on the Duet 2 daughterboard connectorThe bed temperature sensor is connected next to the bed heater output, so I would guess that that is a thermistor.

Height of printer is also a mistery. How can I measure that?

Once you can home the printer to the endstops (you didn't say if my previous advice helped), you can measure the height by moving the nozzle down until it touches the bed, and see how far that is. But I think you have other problems to solve first.

Ian

-

@droftarts

I thinck I fixed all probblems for homing.Next "problem" is printing haha. Error: Attempting to extrude with no tool selected.

-

@thomasvanderwal You have a tool defined:

; Tools M563 P0 D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0CSend

T0to activate it, or click on the 'Tool 0' name in DWC.However, I advise you to follow the 'Commissioning' guide: https://docs.duet3d.com/en/How_to_guides/Commissioning particularly as the reported temperatures are likely to be a long way out.

It would be good if you could answer some of my questions, or responded to my advice with changes you have made. It will help me help you.

Ian