Kinematics issue

-

@cdsmith12 said in Kinematics issue:

M208 X0 Y0 Z0 S1 ; set axis minima

You should allow negative z-min limit. At least during bed-tramming.

Also, you should run G32 twice with a single G30 at bed center in between to reestablish the new Z height. -

@o_lampe dont you mean run G32 twice?

@cdsmith12 you could update your bed file so it continues to run until a set tolerance is reached. we have an example here that will do that https://teamgloomy.github.io/useful_macros.html#bedg-file-for-g32 -

Does the deviation reported by G32 increase or decrease after multiple runs?

-

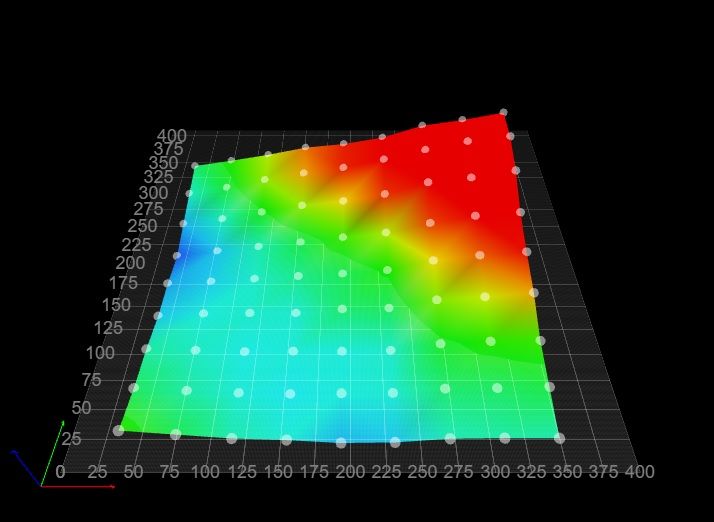

@Phaedrux I homed it and did 4 g32's and then homed it again and did 4 more. Before I homed it the first time, I had manually leveled it and got this height map.

-

It's possible your Y axis on the right side is raised slightly at the back.

-

@Phaedrux I've had a 7mm 6061 Aluminum bed from the beginning 5 years ago or so, and I know it's warped, but mesh compensation always worked ok. I'm thinking that it's been heated so many times that it is warping or flexing during printing.

I decided I'm going to at least eliminate a problem, and just ordered a new cast tooling plate from RatRig so I will get it installed and post an update soon.

Thanks to everyone for the suggestions. This forum never lets me down.

-

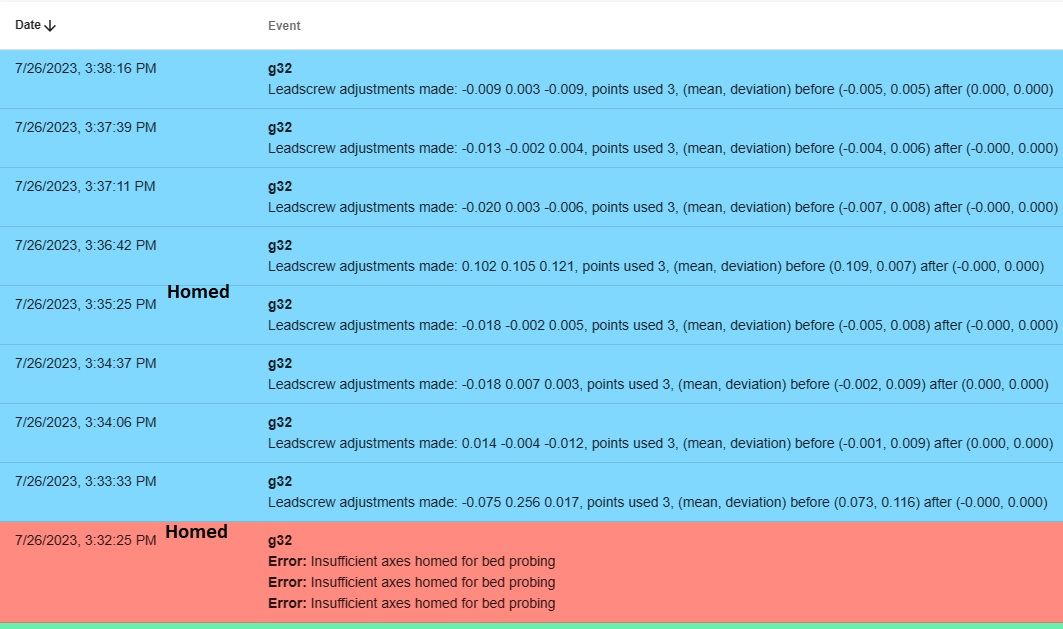

@cdsmith12 If you are going to the expense of using a known flat cast build plate, then may I suggest that you invest a little time and effort and get the frame square so that the build plate is tram with the XY gantries. Your height map suggests that you clearly have a problem with the far right corner of the frame. If you are still going to use mesh compensation, rather than getting XY gantries tram with the bed, then don't waste your money buying expensive tooling plate. Either get the frame tram with the known flat bed thus negating the need for any compensationn, or buy cheap aluminium which isn't guaranteed flat and use compensation. Doing both makes no sense.

-

@cdsmith12 I concur with @Phaedrux and @deckingman: most likely your gantry is skewed.

I had a similar looking height map on my E3D Tool Changer when I first installed it. I tried installing washers under some of the bed mounting points to fix it, but they had much less effect than I expected. Then I realised that the bench that the printer was standing on wasn't level, and this was causing the two Y axis rails on the gantry to be slightly out of parallel. A spirit level confirmed this. I fixed it by raising one of the feet supporting the printer.

-

@deckingman @dc42 Thanks for both of your input. When I rebuilt my printer and went to kinematics back in January, I took the entire frame apart. When I put it back together, I used metal corner and frame brackets for everything, and eliminated all my printed connectors. There's like 60 or so brackets, and it is completely square and level, took me a couple days to loosen one place tighten another, but short of being welded, it can get much better.

The corner that is high is the edge with the single pivot point. When I put a straight edge across, you can see about 1mm gap, and I think that all the negative numbers are what's causing the biggest issue. I tried building it up with tape to the point the magnetic bed almost wouldn't stick on one side. It looked better, but I felt like if it was that warped, i should just get a good new quality plate.

-

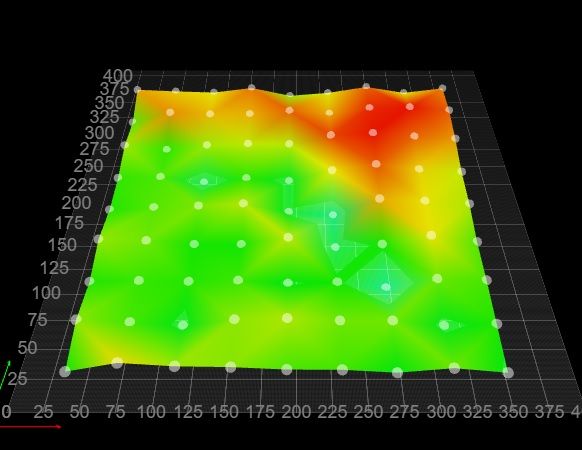

@deckingman appreciate everyone's input. I have not printed yet, but here is the heightmap with the new ratrig brand tooling plate. I did check to make sure everything was still square, but I didn't do anything but take the old 6061 bed off and put the new one on. My guess is either it wasn't truly 6061 when I bought it, or it was warping during print, or both. Will print something later and post an update.

-

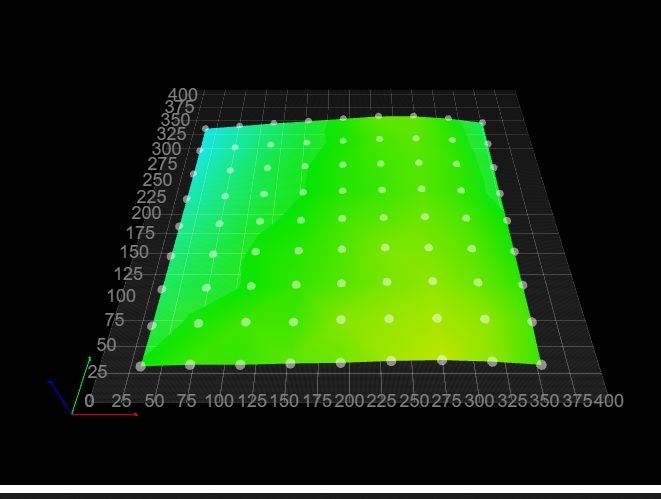

@cdsmith12 That doesn't look too bad. What is your maximum deviation? After tramming my frame, I got my 400mm X 400mm bed flat and level within 0.03mm at every point on the surface. With a little more time and effort, I could probably have improved on that but 0.03 is more than adequate imo. So no auto bed levelling or mesh compensation required or used - just home and go.