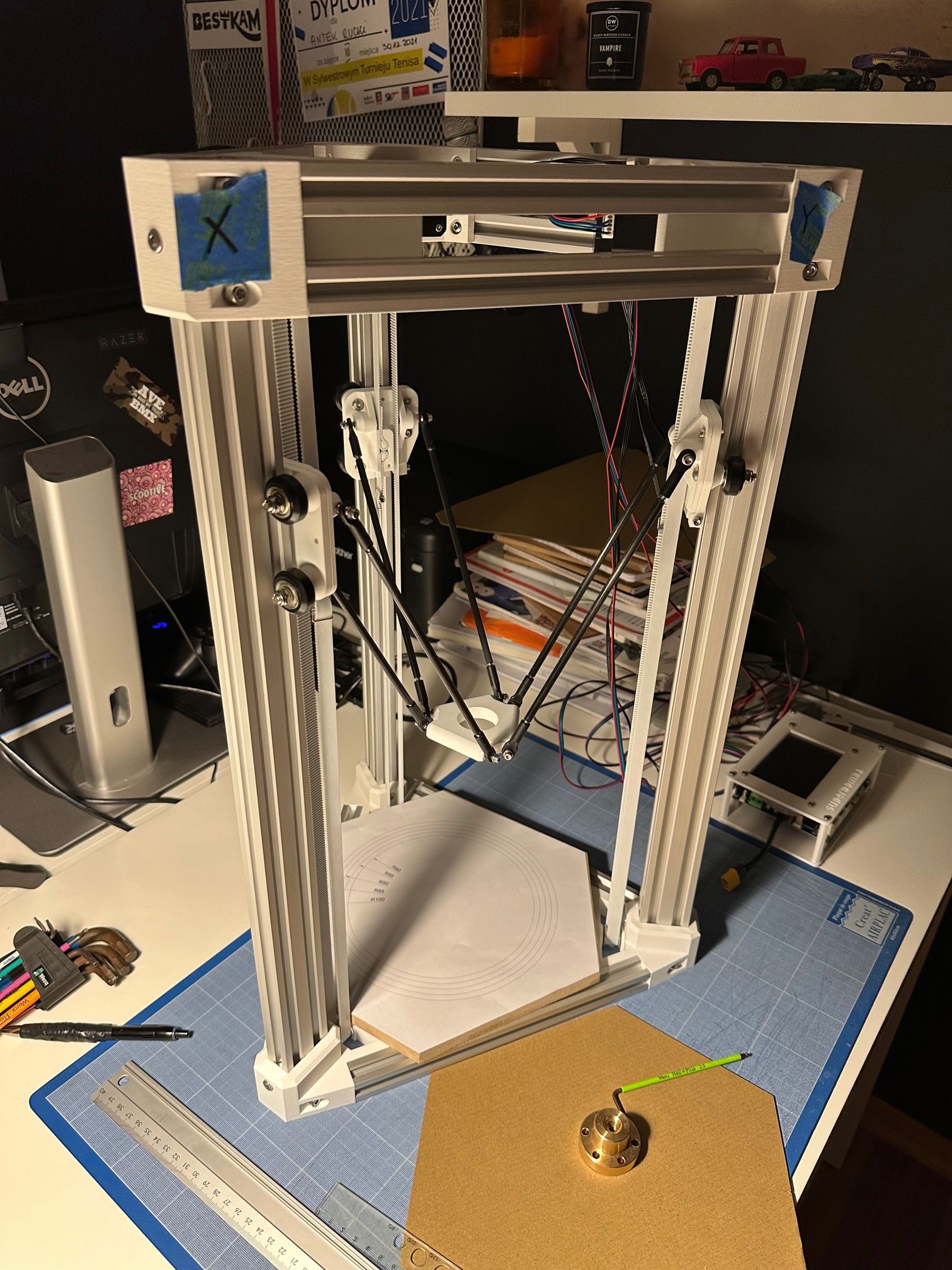

Duet 2 Wifi - largest possible motor

-

@ArekRucki The Duet 2 wifi can output 2.4 amps to steppers but at that current you will need to do active cooling of the board. The board is designed to be cooled from the bottom so you will want to have a fan blow on the bottom of the board.

As for the 2.8amp stepper motors you mentioned, they should be fine since you generally want to drive them at 80% of their rated current which would be 2.24 amps which is within the rating of the duet 2 wifi.

I believe the rule of thumb is you want active cooling over 2amps draw from the stepper drivers.

-

Thanks a lot.

-

@ArekRucki when the board is powered up, the driver sets the phase current to a particular position. When the motor is powered up, it will then jump up to 2 full steps to match that phase position. Normally this process is quite gentle, but your mechanics, motor and gearbox are combining to give that jerk.

To make the process more gentle, you could try the following macro. You haven't said what axis or extruder the motor controls, so in the following I have assumed it is extruder 0.

M913 E30

M17 E

G4 P100

M913 E65

G4 P100

M913 E100

G4 P100

M18 EThis energises the motor at reduced current, ramps up to full current in two stages, then de-energises the motor again.

If that sequence works well, you could put it neat the end of config.g.

-

@dc42 Many thanks for Your answer. Actually this jerk happens with all three X, Y and Z motors - extruder is still the future for me

How should then the macro look like? (I am pretty fresh with g-code).

-

@ArekRucki like this:

M913 X30 Y30 Z30

M17 X Y Z

G4 P100

M913 X65 Y65 Z65

G4 P100

M913 X100 Y100 Z100

G4 P100

M18 X Y Z -

@dc42 Thanks a lot!

-

If you see the 2.8A NEMA23 motors struggle, you can always use stronger external drivers through the expansion connector. It also allows you to use higher voltage for these steppers.

-

@o_lampe

thanks for your suggestion. but what hardware could it be? what expansion connector could I use?

(I am now on 24 V). -

@ArekRucki the expansion break out board allows you to connect external stepper motor drivers to the Duet 3 expansion header:

https://duet3d.com/expansion_breakoutThere are many external drivers, and driver/motor combinations that accept step/direction signals available for different suppliers, at a wide range of capabilities and prices.

-

@ArekRucki Are those steel core belts? Are you aware that the steel wires embedded in the belts fail, allowing the polyurethane belt to stretch over them, resulting in many mysterious print problems?

The problem is that the small pulley diameter requires the steel to flex too much and it fatigues and breaks. If you start having a lot of hard to diagnose problems with print quality, I'd start by checking the belts. -

@mrehorstdmd Thank you. I didn't know that. It is my first build. So I think I'll change the belts...