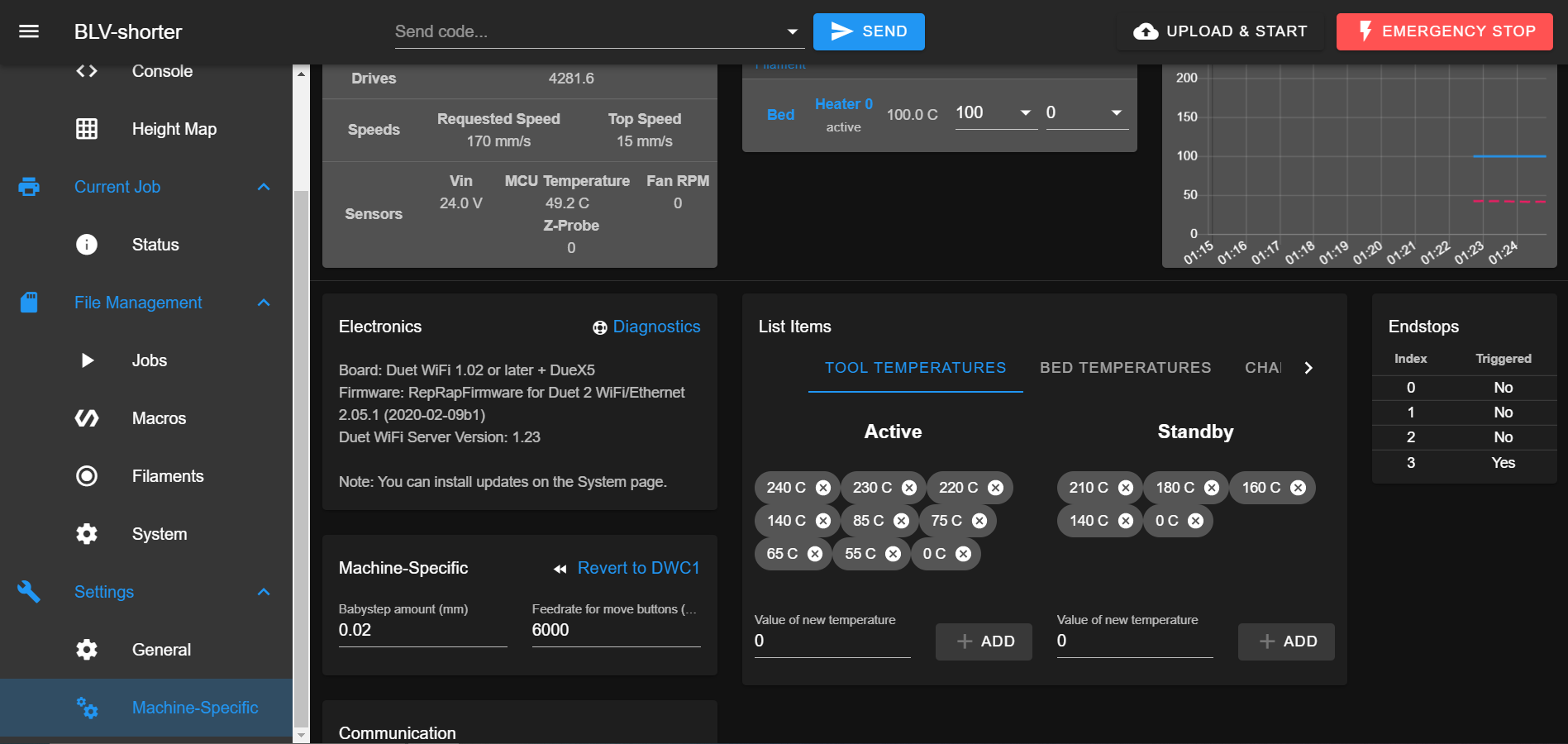

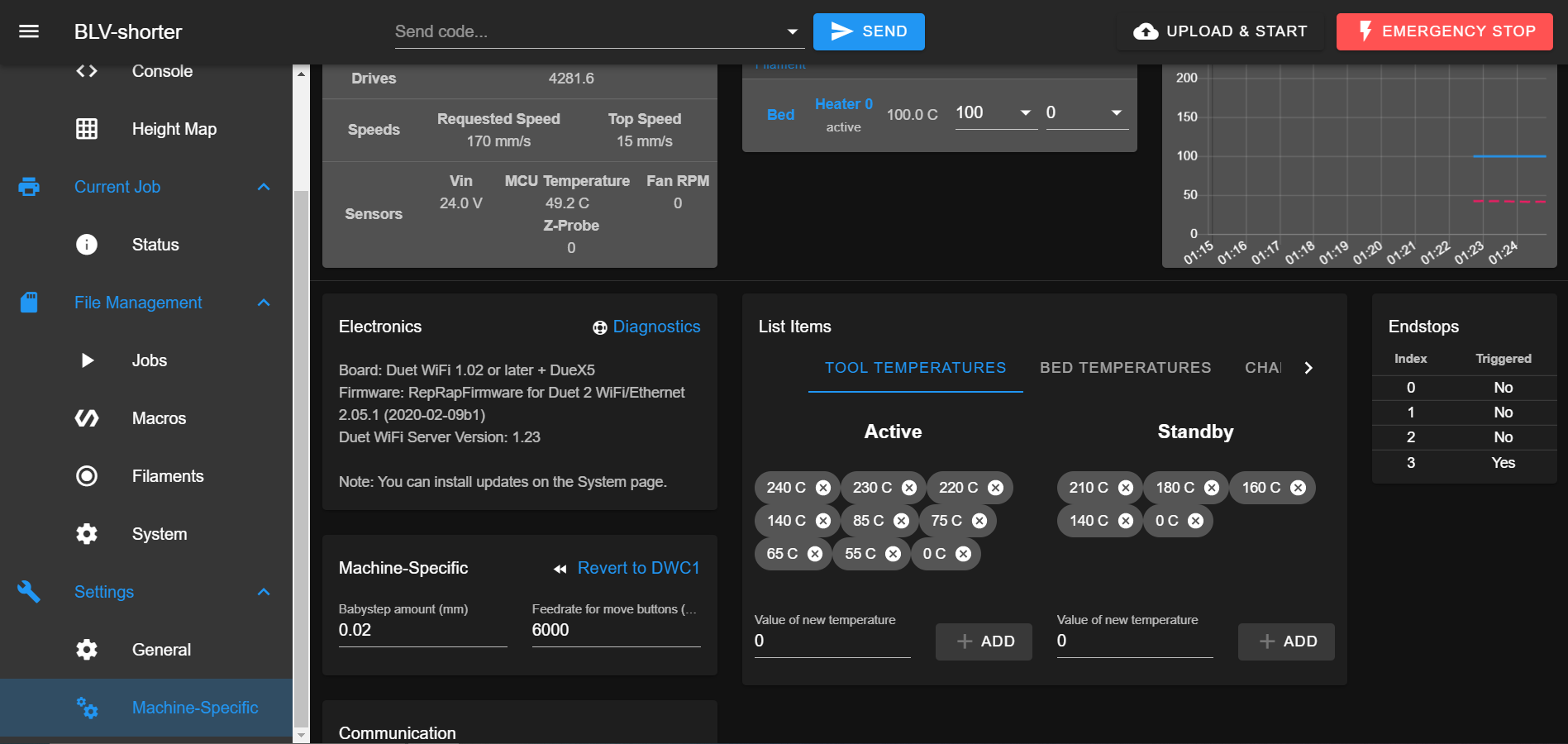

@tinken In the Machine Specific tab on the left side you will see the temperature options for the hotend and heated bed presets.

@tinken In the Machine Specific tab on the left side you will see the temperature options for the hotend and heated bed presets.

I'm sure it's unrelated but you need to look into a better power supply. Looking at your log from when the printer was running your voltage is dropping all the way down to 11.1 so I can see that causing issues.

I would lower your extruder acceleration quite a bit...10000 is rather high, especially for a non-geared extruder which I'm assuming you have due to the low steps/mm on the extruder. I would also raise the instantaneous speed change on the extruder to something between 800-1500.

I just wondering if that real high acceleration on the extruder is causing the issue.

You can mark this as solved.

Turns out for some reason I had to delete my old motion recordings to get the new ones to show up.

They are appearing for me now.

You need to crimp ferrules on the VIN, heated bed and hotend wires otherwise they can loosen up and cause issues.

2mm retraction for a direct drive is at the very limit. You may have too much retraction causing a slight blockage in the heat break. I would reduce it to 1mm and possibly lower for retraction length. For my E3D V6 and bondtech direct drive I am around 1.2mm and retract speed of 35mm/s.

I would recommend increasing your Z and E values in your M566 line. On both of my BLV CoreXY printers my Z instantaneous is set at 150 and my E is 2000.00. The E is most important when using pressure advance to maintain your print speed.

I would also increase the Z value in your M201 line. Mine are set at 50...too low and it can be a bit slow on a layer change increasing the chance of a blob.

It may take some testing to make sure that your extruder can handle this and not skip or chew the filament. I use Bondtech BMG direct drive extruders on all of my printers.

I believe your G31 line is incorrect for your Z. It should be a positive number and not a negative.

For my BL-touch on one of my corexy printers, my G31 line is this

G31 P500 X-25.5 Y-20 Z2.62

With a negative z, that means the probe would be higher than the nozzle and it would never make contact. That might make sense for someone using a piezo sensor where the nozzle itself presses on the bed but not for something like a bl-touch.

Duet boards perform their PWM on the ground side and the positive side stays full voltage. The PWM converter you listed appears to want the PWM on the positive lead so it won't work with the duet. I know I've read there are ways around that but I don't remember what they are.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M303_Run_heater_tuning

Right there it says that it can/will overshoot the target temp when calibrating....by how much depends on how powerful the heater cartridge is. Something to watch out for that I have seen all too often is to make sure you have the correct voltage heater for your hotend. Many people will order a hotend or heater cartridge that is rated for 12 volts yet have a 24 volt power supply...this will make it heat up crazy fast and be pretty much uncontrollable and unsafe.

@bay3d

Here's the stepper section from my Ender 3. I have a pitan extruder (printable titan) so my esteps are different for it.

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S0 ; Drive 3 goes forwards(changed to backwards)

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E408.30 ; Set steps per mm (gregs wade was 604 steps)

M360 E64 ; (My change) set extruder to 64 microsteps

M566 X600.00 Y600.00 Z60.00 E600.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X10800.00 Y9000.00 Z300.00 E3000.00 ; Set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z30.00 E3000.00 ; Set accelerations (mm/s^2)

M906 X850.00 Y850.00 Z850.00 E900.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

You can mark this as solved.

Turns out for some reason I had to delete my old motion recordings to get the new ones to show up.

They are appearing for me now.

I just updated my 6HC and 1LC toolboard along with the DWC to 3.5.0 beta 3. I homed the machine and ran an input shaping Record Motion Profile and they are not showing up in the Input Shaping Plugin under the Motion Analysis tab.

I looked in the files on the SD card and they are recording and being saved under the accelerometer folder and the file sizes look correct as they match other recordings I had done before.

Could there be something I'm missing or that has changed in this update?

Thanks for any assistance.

Also, besides the low z-jerk, your extruder jerk is also very low which can cause issues especially on arcs, circles, etc. I would raise your extruder jerk to at least over 1000.

I tried the 0.9 degree LDO motors but ended up going back to the 1.8degree ones. The 1.8 degree for me are much quieter and I saw no improvement with the 0.9 degree ones so I switched back.

I have a v-core 3.1 500mm using a Duet 6HC, my motor settings are as follows

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S0

M569 P0.4 S0

M569 P121.0 S1 ; physical drive 121.0 goes backwards - lgx forward / BMG backward

M584 X0.0 Y0.1 Z0.2:0.3:0.4 E121.0 ; set drive mapping

M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation

M350 E32 I0 ; try extruder no interpolation

M92 X80.37 Y79.85 Z808.8 E1134 ; TEST CALIBRATION XY STEPS

M566 X800 Y800 Z35 E2000 P1 ; instantaneous /jerk settings)

M203 X21000.00 Y21000.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z200.00 E3600 ; set accelerations (mm/s^2)

M906 X1900 Y1900 Z1700 E600 I30 ; set motor currents (mA) and motor idle factor in per cent - 600 for lgx motor / 900 for BMG

M84 S30

@michaelr123

That is what it says to do in the 1LC documentation...scroll down to where it says Wiring Notes

https://docs.duet3d.com/Duet3D_hardware/Duet_3_family/Duet_3_Toolboard_1LC

@deckingman & @o_lampe

On my big ratrig v-core 3.1 I suspect it has some gantry sag..it's a big printer...500x500. I am re-doing a few things on that right now, replaced the gantry extrusion with a quality one from misumi, re-printed most of the printed parts, new y-linear rails since one that came with it was less than ideal.

I'm really curious to see how it is after all the replacements I'm doing on it. I even had two small custom extrusions cut from misumi to use as alignment spacers for the extrusions the y-rails mount to so they would be precisely lined up.

@deckingman

Yes, I did watch your video and I think I had actually watched it in the past.

I do seem to be getting better prints with the additional probing now but I do think I'll need to tweak my bed mesh manually since there are still a few spots when printing where I'll get the filament ripple on the first few layers from when it is too close.

@deckingman

My leadscrews are actually one in the middle left and two on the right side. I have the railcore II cast bed from 713maker on my BLV cube printers.

I was always under the impression that I was supposed to do my bed.g with probing by the leadscrews but if that's not the case then I'll change that. I assumed that is how it was supposed to be set up since the Duet documentation lists this example:

G28 ; home

G30 P0 X20 Y190 Z-99999 ; probe point 0 near a leadscrew

G30 P1 X180 Y190 Z-99999 ; probe point 1 near a leadscrew

G30 P2 X100 Y10 Z-99999 S3 ; probe point 2 near a leadscrew and calibrate 3 motors

Should I still probe by the leadscrews and then add additional locations such the left rear, left front and also the right center and then rear center and front center?

Something like this

M562 ;clear bed transform

G28 ;home all

M401 P0 ;pickup Euclid probe

G30 P0 X310 Y32.5 Z-99999 ; right front leadscrew

G30 P1 X310 Y179 Z-99999 ;right center

G30 P2 X310 Y287.5 Z-99999 ; right rear leadscrew

G30 P3 X40 Y290 Z-99999 ;left rear

G30 P4 X40 Y159.5 Z-99999 ;left center leadscrew

G30 P5 X40 Y30 Z-99999 ;left front

G30 P6 X138 Y30 Z-9999 ;front middle

G30 P7 X138 Y290 Z-99999 S3 ;rear center

G1 X138 Y179 F9000 ;go to center of bed in advance of probe that point

G30 ;probe center to re-establish Z

M402 P0 ;Return Euclid probe

I just tried it and it only ran it once but I know for sure if I run it again the deviation is not going to be 0.000 like the results say.

I guess I need to need to try and learn how to program this so it automatically runs the probing at least 3 times but I'm totally clueless with this stuff unfortunately...lol.

It's not a problem, just trying to save time from having to manually run my "equalize leadscrews" macro multiple times until everything is within what I believe is an acceptable deviation between my 3 leadscrews.