NEMA 23 Drama

-

@joaquin_suave You can get this one - https://ro.mouser.com/ProductDetail/Cosel/PJMA1000F-36?qs=DRkmTr78QARflml570Qxjw%3D%3D - while announced for 36V, it can be adjusted from 30.8V to 40.8V. Unfortunately 32V is not that usual and 20A is anything but low current...

-

What does "can't get NEMA 23 motors to BEHAVE at all" mean?

Maybe the problem is not the power supply... -

I tested the motors several times with a multitude of different configurations (steps/ mm, microstepping, and current) an the only results I got was a "studering" of the spindle (like 1/20 of a rotation) regardless of my desired manual travel request (1mm, 10mm, 50mm).

Due to my lack of confidence in my skills... I tried some of the same tests with a Nema 17 motor and it performed exactly like it should.

I admit I am a total NOOB when it comes to the configuration of control systems and invested in this project as a learning experience. I guess this is a classic case of "be careful of what you wish for"!

Here is my device with my 8 pallet mill in the backround:

-

@joaquin_suave what motor currents, axis step/mm and accelerations did you set on the Duet? Use M906, M92and M203 to check.

If you are in a country with 110V mains voltage, check whether your PSU has a mains voltage selector switch, and if so that it isn't set to 220V.

-

Can you share your config.g? Also share the results of M122 and M98 P"config.g"

-

Thank you guys SO MUCH!

I am sure the PSU is set to 110V and the tried my other PSU (@ 4A) and had the same results.

To give you a little back round about the device, It was originally intended to be used in an "all-terrain" environment, all weather, and any of the axis able to take "hit". That is why I designed the drives to be rack & pinion with a 3.75:1 reduction by belt drive. If the axis gets hit it can skip a tooth then quickly "homed" and reset with minimal damage to the hardware.

I am going to order the suggested PSU right now the go dig through my notes then post steps/mm and the other configurations later today.

BTW: I am turning it into a 3D printer with a 400mm cube and eventually fully enclosed.

Thank you all again for your input!

-

@joaquin_suave I suggest you check the wiring of the NEMA 23s. Unfortunately there is no standard for which colour wires go with each motor phase and it my be different between the two. You need to identify which pair of wires are associated with each phase and wire them accordingly. I'm using my phone right now and am 10,000 miles away from home so I can't provide links but there guides on how to do that.

-

If you are using external drivers you may need to tweak the timing parameters for the step/dir/enable lines to get them to work reliably.

-

I have checked the wiring of both the motors per the Duet documentation and A+/- & B+/- are paired correctly and I am using the drivers on the Duet3 HC board.

The new PSU is ordered and should be here Thursday!

-

its very unlikely that its a power supply issue .

did those motors ever work ?

i ran nema23 with 24v supply without any issues -

Yes both the motors work fine with a simple drive powered by a 24V 4a PSU.

-

I use NEMA 23's with my Duet3 board with no issues. I also think you should check you wiring. My method with NEMAs is to disconnect the motor , then short two of the wires together. If they are on the same winding, the shaft will be hard to turn. If the shaft still turns easily, they are on different windings. Test a few combos to convince yourself you've got one pair of wires for each winding. Now you can connect them to the duet connector with confidence. If the motor turns in the wrong direction, you can adjust that in your M569 command.

Also, double check your M906 command (max motor currents). Be sure to put in your current in milliamps, probably something around 2200 for a NEMA 23 (derated to 80% of max current).

And congratulations on making it to the age of "do what you want". Lot's of us old coots here that also don't have anything better to do.

-

Can you please post the make and model of the NEMA23 motors, or photos of the labels (or both) ?

And also details of the "simple" drive that they do work with - again make and model, photos of any wiring diagrams or terminal layouts??

There are some types of motor that could work with an external drive of an appropriate type, but not be compatible with the Duet motor drivers.

-

I have checked all the motors for paired windings by checking resistance and by shorting them and spinning the shaft. I am 100% sure that the wiring is correct.

The 2 motors I plan on using are Intelligent Motion Systems M-2231-2.4S

And... No luck!I also tried an Oriental Motors C0145-9212K... No luck!

And an Oriental Motors PK268-E2.0A... No luck!All these motors work correctly with an external drive.

I have to run out and meet with a client for few hours. When i get back to the shop I'll share the setting that I have tried in the RRF Config tool.

Thanks again to all of you for "pitching in"!

-

@joaquin_suave

OK, the motors don't look to be anything particularly special.

The specifications are not much different from some I use.Info here:

https://www.motionsolutions.com/store/pc/viewPrd.asp?idproduct=1209Presumably you are using Red & Red/White as one winding and Green & Green/White as the other?

They are fairly high inductance, so will need moderate instantaneous speed change and acceleration settings, at least to start with.

-

@joaquin_suave Is there any chance you have one of the windings reversed at the driver connections?

-

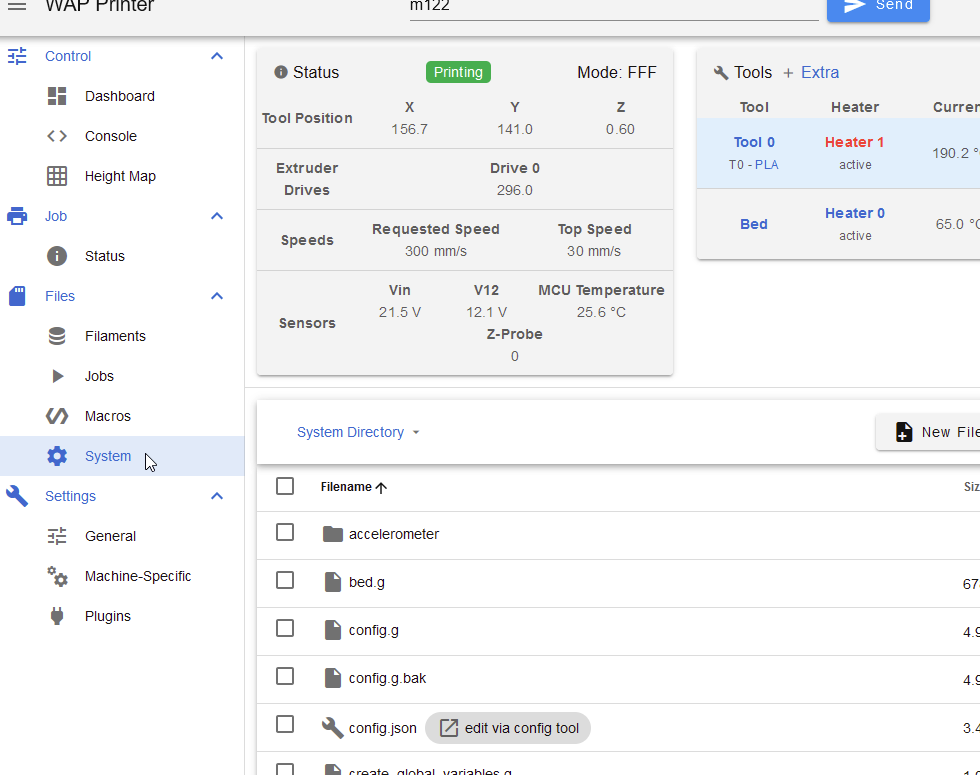

Here is my M122 info:

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.3 (2021-06-15 21:45:47) running on Duet 3 MB6HC v1.01 or later (standalone mode)

Board ID: 08DJM-9P63L-DJ3S0-7JTD0-3S46L-TUKZ8

Used output buffers: 3 of 40 (12 max)

=== RTOS ===

Static ram: 150904

Dynamic ram: 91692 of which 0 recycled

Never used RAM 111596, free system stack 193 words

Tasks: NETWORK(ready,30.3%,270) ETHERNET(notifyWait,0.1%,117) HEAT(notifyWait,0.0%,325) Move(notifyWait,0.0%,284) CanReceiv(notifyWait,0.0%,944) CanSender(notifyWait,0.0%,374) CanClock(delaying,0.0%,333) TMC(notifyWait,7.7%,59) MAIN(running,61.8%,1096) IDLE(ready,0.0%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:09:16 ago, cause: software

Last software reset at 2022-03-17 13:47, reason: User, GCodes spinning, available RAM 111596, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 148

MCU temperature: min 34.0, current 36.9, max 36.9

Supply voltage: min 36.0, current 36.0, max 36.1, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.2, under voltage events: 0

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 730913, standstill, reads 19469, writes 14 timeouts 0, SG min/max 0/0

Driver 1: position 0, standstill, reads 19456, writes 27 timeouts 0, SG min/max 0/179

Driver 2: position 0, standstill, reads 19469, writes 14 timeouts 0, SG min/max 0/0

Driver 3: position 0, standstill, reads 19469, writes 14 timeouts 0, SG min/max 0/0

Driver 4: position 0, standstill, reads 19472, writes 11 timeouts 0, SG min/max 0/0

Driver 5: position 0, standstill, reads 19473, writes 11 timeouts 0, SG min/max 0/0

Date/time: 2022-03-17 13:56:29

Slowest loop: 6.84ms; fastest: 0.05ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 2.1ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, maxWait 219077ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 21, completed moves 21, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 21], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== CAN ===

Messages queued 5011, received 0, lost 0, longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 49 (min 49), ts 2785/0/0

Tx timeouts 0,0,2784,0,0,2225 last cancelled message type 30 dest 127=== Network ===

Slowest loop: 4.60ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 1 of 8- Ethernet -

State: active

Error counts: 0 0 1 0 0

Socket states: 5 2 2 2 2 0 0 0

========

Help me guys! I am more confused than ever! - Ethernet -

-

m203

Max speeds (mm/min): X: 12000.0, Y: 12000.0, Z: 180.0, E: 1200.0, min. speed 30.00

3/17/2022, 2:52:11 PM m106

3/17/2022, 1:58:43 PM m98 p

Error: M98: non-empty string expected=========

When i am trying to make changes, i go into the RRF config tool and create a new zip file the download it in "my printer". It goes through the process then tells me that only one file has changed... I presumed that it was the config.g, but don't know for sure.Am I missing something... I'm starting to feel really dumb here!

-

I think everything you put into the configurator ends up in one file - config.g. Config.g is in the sys directory of the downloaded file set. It's a text file that you can edit yourself with any text editor. It is usually not too complicated and has some good comments in it. You can use the gcode disctionary in the documentation (https://docs.duet3d.com/en/User_manual/Reference/Gcodes) to look up what each of the gcodes are doing, and you'll quickly see how they map to the things you put into the configurator. You'll pretty quickly never go back to the beginning with the configurator again.

If you are connecting to the duet board via the web interface (are you?), you'll see a link to the "System" page next to the gear icon on the left side of the page. When you select that link you'll see a list of those same files that you installed. You can right-click on any of them to edit, and you'll see config.g right there.

One warning - if you do edit those files right on the system, you should definitely keep a copy somewhere off the duet board. You can download a file after you've changed it. My personal; preference is to always edit a copy of any file on my PC and upload it to the duet board. That way, I know I have a backup copy.

-

@joaquin_suave said in NEMA 23 Drama:

i go into the RRF config tool and create a new zip file the download it in "my printer".

Once you have everything in the printer the first time, I'd suggest just modifying the config in place via the web editor.

The config tools does a good job of a general setup but then you really need to do the "fine tuning" for your specific machine by hand.

I actually save the entire config for each machine on another PC (in fact on network storage) and edit files there, then drop the updated file(s) back on the machine via the DWC web page.

That way if anything goes wrong during an update, I can just drop the whole lot back on a new SD card setup via DWC and it's working again straight away, with no messing about.