abnormal noise when changing direction

-

@nok please switch to spreadCycle again, run M569 to confirm that the drivers are in spreadCycle mode, and record the sound again, so that we can eliminate stealthChop from the suspects. Also, when the arc is being printed, watch the "Requested speed" and "Top speed" figured in DWC and see whether they are the same.

If you post the GCode file or make it available on Dropbox or Google Drive etc. then I can try it on my delta.

-

@dc42

i think you want eliminate me from the list of suspects or…

or…

maybe you are robots and can't read my above posts correctly?

let's find out…

i’ve been trying to find the error myself for weeks now. i’ve read mountains of forum posts and i tried (like i said in my previous posts), who knows how many different settings for jerk, speed, acceleration, currents, pressure advance, retraction… all in spreadcycle as well as in stealthchop mode, with 1.8° and 0.9° stepper + different cables. with and without slicer, extruder and hightmap involved… the whole spectrum up and down. but this problem is ALLWAYS present.

through my years of experience with 3d printers, i would say that something is fundamentally wrong and not setting related. with the old chinaboard (also with 2209), this printer was super quiet and work totaly fine before i switch to a duet board.i did the moves in the audio recording without a slicer generated gcode, i use only dry G1 and G3 commands send via dwc. so, don't waste your time with the print of my gcode. and btw time; thank you very very much for yours, both of you! i’m very thankful for your help!

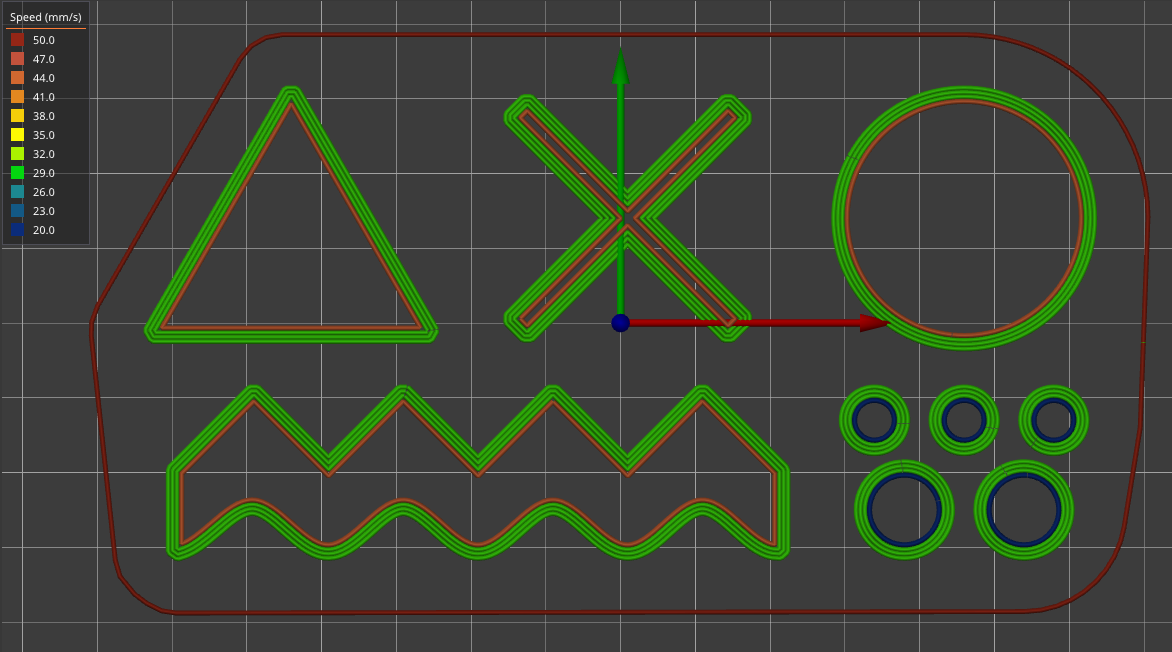

i made a new testprind where you can hopefully better see/hear whats going on in curve sections. in the first part of the video, hotend and part fans are turned of, so what you hear are only the motors. requested speed and top speed are always the same in dwc.

spreadcycle is selected in config and active

video and gcode;

https://www.dropbox.com/sh/yx5jcgkur043o28/AABUWS92N_xOGplWzZ4uFLeLa?dl=0 -

@nok I'm sorry, somehow I missed that your sound recording was taken in spreadCycle mode. I'll review your latest video tomorrow. As it happens, today I finished converting my delta to Duet 3 Mini, so I will be able to run your code on it.

-

@dc42

any news regarding the problem?

to rule out the firmware as well, i updated to 3.4.0RC2, but nothing changed. -

@nok sorry no news yet, I've been busy with other things today.

-

@dc42

any news after 10 days? -

@nok I've listened to your video again I don't think those noises are anything unusual. What I think is happening is that when drawing the large circles, the step frequencies of the motors vary through a wider frequency range than they do when printing straight lines, and at one point the frequency is exciting a resonance in your mechanics. The high microstepping capability of Trinamic drivers makes them quieter in normal operation; which means that when you do encounter a resonance, it stands out more.

It may be the stepper motor mid-band resonance that is being excited. See https://phidgets.wordpress.com/2014/07/28/how-to-avoid-resonance-issues-in-stepper-motors/ for more details.

The frequency of mid-band resonance varies approximately with the square root of motor current; so you may find that the pitch of the vibration varies with motor current.

-

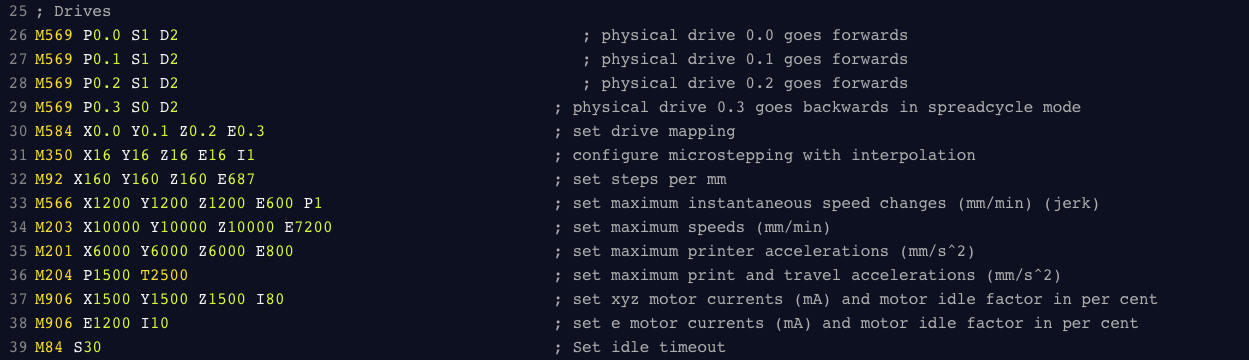

@dc42

please check out my new videos. this time (as in the audio file) the moves are in stealthchop mode.

i entered the commands via DWC. i think that's more meaningful (especially the slow movements) than hearing it while printing.https://www.dropbox.com/sh/ykwktk4sa2ofbp5/AAAD-Bu4OODBZYTiuBmcgl94a?dl=0

= = = = = = = = = = = moves

FAST:

G1 X130 Y0 Z150 F2700

G1 X-130 Y0 Z150 F2700

G3 X0 Y-130 I130 Z150 F2700SLOW:

G1 X130 Y0 Z150 F500

G1 X-130 Y0 Z150 F500

G3 X0 Y-130 I130 Z150 F500= = = = = = = = = = = config.g

; configuration file for duet3 mini5+ (fw v3.3)

; executed by the firmware on start-up

; NOK/TRIP/GU04

;

; General preferences

G90 ; send absolute coordinates

M83 ; but relative extruder moves

M550 P"GU04" ; set printer name

M665 R151.67 L315 B132 H320 ; set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; miniDisplay

M918 P2 E4 F2000000 C35 ; configure direct-connect display fysetc 12864mini

M150 X2 R213 U254 B0 P255 S1 F1 ; display led (r=green u=red b=blue)

M150 X2 R85 U0 B255 P255 S1 F1 ; left encoder led (r=green u=red b=blue)

M150 X2 R85 U0 B255 P255 S1 F0 ; right encoder led (r=green u=red b=blue); Drives

M569 P0.0 S1 D3 ; physical drive 0.0 goes forwards in stealthchop mode

M569 P0.1 S1 D3 ; physical drive 0.1 goes forwards in stealthchop mode

M569 P0.2 S1 D3 ; physical drive 0.2 goes forwards in stealthchop mode

M569 P0.3 S0 D2 ; physical drive 0.3 goes backwards in spreadcycle mode

M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160 Y160 Z160 E687 ; set steps per mm

M566 X1200 Y1200 Z1200 E600 P1 ; set maximum instantaneous speed changes (mm/min) (jerk)

M203 X10000 Y10000 Z10000 E7200 ; set maximum speeds (mm/min)

M201 X6000 Y6000 Z6000 E800 ; set maximum printer accelerations (mm/s^2)

M204 P1500 T2500 ; set maximum print and travel accelerations (mm/s^2)

M906 X1050 Y1050 Z1050 E1200 I60 ; set xyz motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io5.in

M574 Y2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io6.in

M574 Z2 S1 P"io3.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io2.in; Z-Probe

M558 P5 C"^!io4.in" H5 F120 T5000 ; set Z probe type to switch and the dive height + speeds (def t6000)

G31 P500 X0 Y0 Z18.10 ; set Z probe trigger value, offset and trigger height

M557 R130 S20 ; define mesh grid; Heater Bed

M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S100 ; set temperature limit for heater 0 to 100C; Heater Hotend

M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as E3D thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"out3" Q100 ; create fan 0 on pin out3 and set its frequency

M106 P0 C"PartFan" S0 H-1 ; set fan 0 name and value. thermostatic control is turned off

M950 F1 C"out4" Q30 ; create fan 1 on pin out4 and set its frequency

M106 P1 C"HotFan" S0.70 H1 T50 ; set fan 1 name and value. thermostatic control is turned on

M950 F2 C"out5" Q30 ; create fan 2 on pin out5 and set its frequency

M106 P2 C"CaseFan" S1 H-1 ; set fan 2 name and value. thermostatic control is turned on; Tools

M563 P0 S"GU04-EX3" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

M207 S4 F7200 Z0.0 ; firmware retraction

M572 D0 S0.35 ; pressure advance; Miscellaneous

M501 ; load saved parameters from non-volatile memory

T0 ; select first tool= = = = = = = = = = = config-override.g

; config-override.g file generated in response to M500 at 2022-02-28 03:36

; This is a system-generated file - do not edit

; Delta parameters

M665 L315.000:315.000:315.000 R151.137 H336.422 B132.0 X-0.892 Y0.127 Z0.000

M666 X0.005 Y0.022 Z-0.027 A0.00 B0.00

; Heater model parameters

M307 H0 R0.331 K0.479:0.000 D1.92 E1.00 S1.00 B0

M307 H1 R2.073 K0.286:0.194 D6.29 E1.00 S1.00 B0 V23.8

; Z probe parameters

G31 K0 P500 X0.0 Y0.0 Z18.10

; Workplace coordinates

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00= = = = = = = = = = = homedelta.g

; homedelta.g

; called to home all towers on a delta printer

;

G91 ; relative positioningM17 X Y Z ; enable XYZ motors

G4 P150 ; wait 150ms to allow the driver to establish the motor parametersG1 H1 X505 Y505 Z505 F1500 ; move all towers to the high end stopping at the endstops (first pass)

G1 H2 X-5 Y-5 Z-5 F1500 ; go down 5mm

G1 H1 X10 Y10 Z10 F360 ; move all towers up once more (second pass)

G1 Z-5 F1500 ; move down 5mm so that the nozzle can be centred (disable for calibration)

G90 ; absolute positioning

G1 X0 Y0 F1500 ; move X+Y to the centre (disable for calibration)= = = = = = = = = = = M122

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.3RC2 (2021-05-11 14:55:40) running on Duet 3 Mini5plus Ethernet (standalone mode)

Board ID: 6NRMG-K967A-G65J0-401GQ-KN82Z-ZAJLH

Used output buffers: 3 of 40 (12 max)

=== RTOS ===

Static ram: 102476

Dynamic ram: 107108 of which 0 recycled

Never used RAM 34120, free system stack 117 words

Tasks: NETWORK(ready,25.7%,208) ETHERNET(notifyWait,0.2%,572) HEAT(delaying,0.0%,336) Move(notifyWait,0.1%,278) CanReceiv(notifyWait,0.0%,943) CanSender(notifyWait,0.0%,357) CanClock(delaying,0.0%,341) TMC(notifyWait,0.7%,106) MAIN(running,72.4%,426) IDLE(ready,0.0%,29) AIN(delaying,0.8%,264), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:28:32 ago, cause: power up

Last software reset at 2022-03-04 05:15, reason: User, GCodes spinning, available RAM 34120, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Aux1 errors 0,0,0

MCU revision 3, ADC conversions started 1712968, completed 1712968, timed out 0, errs 0

Step timer max interval 1378

MCU temperature: min 26.7, current 35.0, max 35.2

Supply voltage: min 24.0, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 97247, standstill, SG min/max 0/42, read errors 0, write errors 0, ifcnt 28, reads 24393, writes 28, timeouts 0, DMA errors 0

Driver 1: position 97247, standstill, SG min/max 0/38, read errors 0, write errors 0, ifcnt 28, reads 24393, writes 28, timeouts 0, DMA errors 0

Driver 2: position 97247, standstill, SG min/max 0/54, read errors 0, write errors 0, ifcnt 28, reads 24393, writes 28, timeouts 0, DMA errors 0

Driver 3: position 0, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 12, reads 24408, writes 12, timeouts 0, DMA errors 0

Driver 4: position 0, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 9, reads 24412, writes 9, timeouts 0, DMA errors 0

Driver 5: position 0, assumed not present

Driver 6: position 0, assumed not present

Date/time: 2022-03-05 04:03:10

Cache data hit count 2926781252

Slowest loop: 85.06ms; fastest: 0.09ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 22.5MBytes/sec

SD card longest read time 3.7ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 864929ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 5937, completed moves 5937, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 26], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1, chamberHeaters = -1 -1

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== CAN ===

Messages queued 15417, send timeouts 15414, received 0, lost 0, longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 17 (min 17)

Last cancelled message type 30 dest 127

=== Network ===

Slowest loop: 7.00ms; fastest: 0.03ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- Ethernet -

State: active

Error counts: 0 0 0 0 0

Socket states: 2 2 2 2 2 0 0 2

- Ethernet -

-

@nok on the last move of the slow move video, I can here some mechanical creaking noises. I think they are probably caused by a sticking ball joint, or possibly a sticking linear rail.

-

i searched and found this topic. today i ran a certain gcode file which contained round circles and my printer, really the extruder, made extremely loud grinding noises. the sounds were quite severe. i suspect it might be the same thing as this thread. all i can describe is loud grinding.

this is on the first layer, when making a perfect circle approximately 40 mm diameter. as soon as the circle is done, the extruder goes back to dead silence making other shapes like squares, lines, etc.

is there a way i can troubleshoot this?

but if i run something like the voron cube which has the round center, the machine flies quickly thru that circle smoothly and silent.

config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core3" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Network M552 S2 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet G4 S2 ; wait for expansion boards to start ; Drives M569 P0.0 S0 D2 ; Left Z physical drive 0.0 goes forwards M569 P0.1 S0 D2 ; Rear Z physical drive 0.1 goes forwards M569 P0.2 S0 D2 ; Right Z physical drive 0.2 goes forwards M569 P0.3 S1 D2 ; Right physical drive 0.3 goes forwards M569 P0.4 S1 D2 ; Left physical drive 0.4 goes forwards M569 P121.0 S1 D2 ; Extruder physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E690 ;E400 ; set steps per mm M906 X2000 Y2000 Z1800 E1000 I10 ;E700 I30 ; set motor currents (mA) and motor idle factor in per cent -- safe for Duet 3 mini 5+ M84 S30 ; Set idle timeout M566 X1000.00 Y1000.00 Z6.00 E300 P1 ;E120.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1000.00 E7200 ;E3600.00 ; set maximum speeds (mm/min) M201 X10000.00 Y10000.00 Z100.00 E10000 ;E3600.00 ; set accelerations (mm/s^2) M207 S0.6 F7200 Z0.2 ; firmware retraction orbiter 2.0 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X310 Y310 Z300 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io2.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M671 X-4.5:150:304.5 Y-4.52:305:-4.52 S5 ; define positions of Z leadscrews or bed levelling screws M557 X30:280 Y20:290 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Keenevo 600W Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 Q10 ; Define Heater0 as the heated bed, bind to Sensor0 M140 H0 P0 ; Define Heated Bed M307 H0 R0.602 K0.401:0.000 D2.44 E1.35 S1.00 B0 ; PID Tuning for Heater0, Heated Bed (100C) M143 H0 S120 ; Set temperature limit for Heater0 to 120C M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7.060000e-8 A"Slice Hotend" ;Slice Engineering 300C thermistor, settings are online M950 H1 C"121.out0" T1 Q100 ; Define Heater1 as Extruder0 heater, bind to Sensor1 M307 H1 R3.030 K0.444:0.000 D4.49 E1.35 S1.00 B0 V23.8 ; PID Tuning for Heater1, Extruder0 (240C) M143 H1 S285 ; Set temperature limit for heater 1 to 285C M308 S2 Y"drivers" A"4028 Power" ; 4028 power using spare heater ;M308 S2 P"temp2" Y"thermistor" A"Chamber" T100000 B4725 C7.060000e-8; Define Sensor2 as Chamber temperature (Semitec 104GT2) M308 S3 Y"mcu-temp" A"MCU" ; Define Sensor3 as the integrated MCU temperature sensor M308 S4 Y"drivers" A"TMC Drivers" ; Define Sensor4 as the TMC overheat sensor ; Fans M950 H2 C"!out2" T2 Q10 ; Define Heater2 as the 4028 fan power, bind to Sensor2 M143 H2 P2 S200 ;M307 H2 I1 S1 ;M106 P2 C"4028 Power" S0 H-1 ;M950 F0 C"121.out1" Q500 ; create fan 0 on pin out4 and set its frequency M950 F0 C"!121.out1+out1.tach" Q25000 M106 P0 C"Layer Fan" L0.0 X1.0 S0 H-1 B0.1 ;M106 P0 C"Layer Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off ;M950 F1 C"out3" Q500 ; create fan 1 on pin out3 and set its frequency M950 F1 C"121.out2+out2.tach" Q500 ; Fan 1 uses out3, and using out3.tach as a tacho input M106 P1 C"Hotend Fan" S0 H1 T45 ; set fan 1 name and value. Thermostatic control turned on for Hotend M950 F2 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P2 C"Board Fan" S0 H2:3:4 T46 ; set fan 1 name and value. Thermostatic control turned on for Hotend ; Tools M563 P0 D0 H1 F0 S"Mosquito Magnum" ; define tool 0 G10 P0 X0 Y0 Z0 R0 S0 ; set tool 0 axis offsets, set initial tool 0 active 60C and standby temperatures to 0C ;M563 P0 H0 F0 S"Keenevo 600W Bed" ;G10 P0 X0 Y0 Z0 ;G10 P0 R50 S0 ; EVA 2 / BMG / E3D V6 ;M92 E400 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) ;M906 E800 ; set extruder motor current (mA) and idle factor in per cent ;M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hotend" ;; Run Heater PID Tune!! ;; M307 H1 A751.5 C196.6 D4.7 S1.00 V23.9 B0 ; Z-Probe ;; Inductive Probe ;M558 P5 C"io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds M558 P8 C"121.io0.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds G31 P1000 X-28 Y-15 Z1.02 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;G31 P500 X-30 Y-15 Z0 ;; BLTouch ; M950 S0 C"io7.out" ; Create a servo pin on io7 ; M558 P9 C"io7.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P25 X-28.00 Y-13.00 Z0.78 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;Accelerometer M955 P121.0 I16 ;Input Shaper M593 P"zvdd" F44 ; for 10k acceleration ;M593 P"mzv" F42.5 ; for 15k acceleration ;Filament Sensor0 M591 D0 P3 C"121.io1.in" S1 M591 D0 L27 R10:190 ;PanelDue 5i M575 P1 S1 B57600 ;NeoPixels x3 M150 X1 Q4000000 ;R128 U128 B128 P128 S2 F0 M150 X1 R255 U255 B255 P255 S2 F0 ; display led ; Custom settings are not configured G29 S1 M572 D0 S0.065; set Pressure Advance K-factor M501 ; init print time logging if !exists(global.runtime) M98 P"runtime.g" ; init LED variables if !exists(global.warmUp) global warmUp = false ; Select default tool M404 N1.75 ; Define filament diameter for print monitor T0 -

@RogerPodacter said in abnormal noise when changing direction:

M566 X1000.00 Y1000.00 Z6.00 E300

You may want to raise your Z and E jerk values. 6mm/min is very slow and could be limiting your XY movement in unexpected ways especially if you have mesh compensation active. Same can be said for a too low E jerk value. A circle is made up of many small segments, and with a low jerk value the extruder may be trying to halt at each segment connection. Try increasing your E jerk to 1000, 2000, or even 3000. And increase your Z jerk to at least 60.