TC coupler stall detection. custom.how?

-

@barbarossa-cologne it seems E3D have changed their support pages over from dozuki to zendesk

https://e3d-online.zendesk.com/hc/en-usI'm sure someone here might be able to help you though

-

@engikeneer

OK thanks a lot. I´ll try to solve as much as I can by myself.

R.G. -

@barbarossa-cologne

Would be nice if anybody can take a look over my config. Maybe it´s a small mistake of me. -

a homec.g file is needed. It contains the instructions to drive the C axis until the stepper drivers detect a stall. E3D's sys files are on github, see their homec.g file

-

@jannau ok thanks

I saw it´s for rrf2. Does this matters?

-

@barbarossa-cologne Found it for rrf3 ... sry

-

@barbarossa-cologne stall detection seems to be missing for the C motor, see E3D's config.g

-

@jannau

ok it´s done. Homing is working.

thanks a lot

R.G. -

@barbarossa-cologne

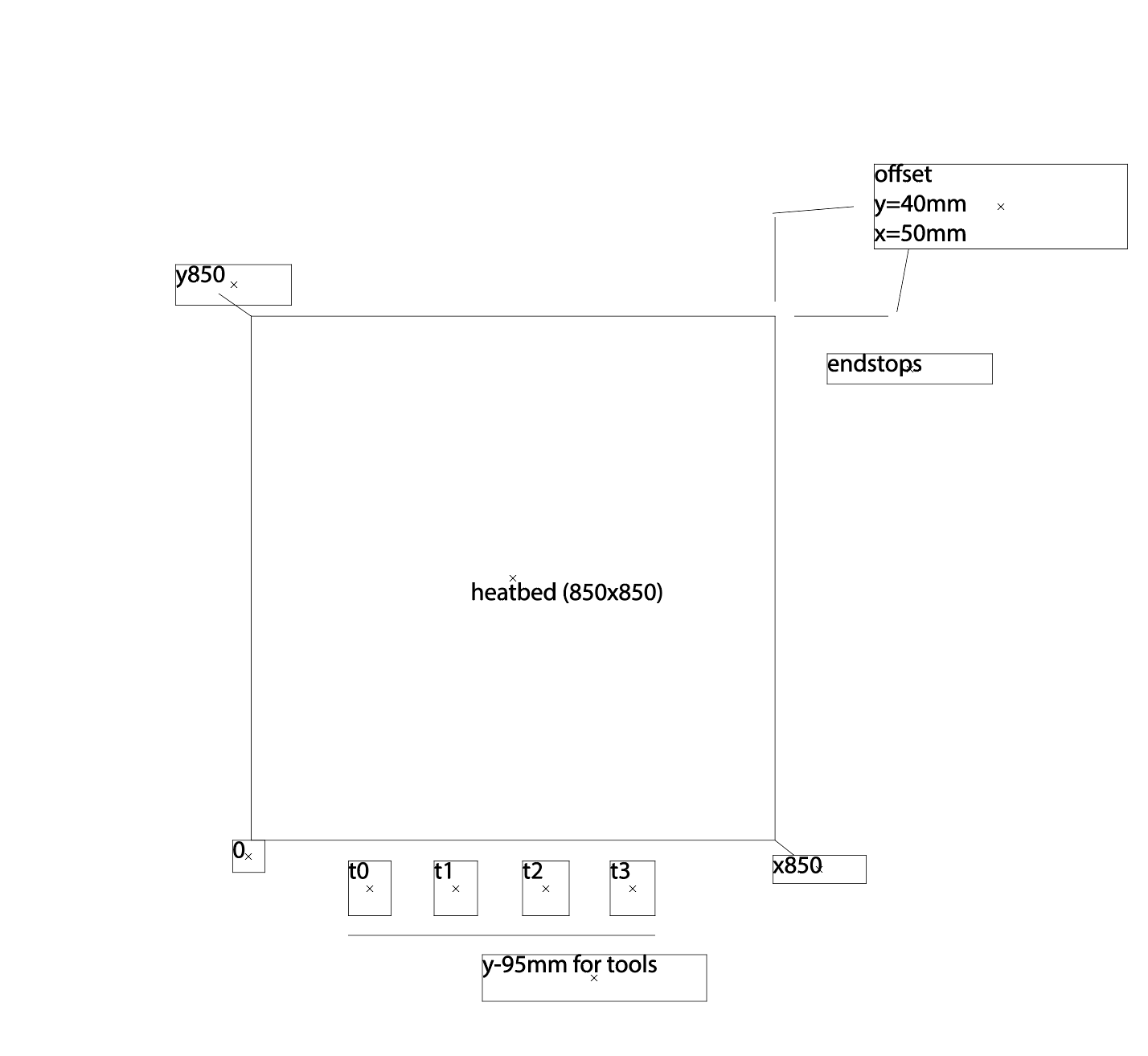

How can I add a general offset?

I have defined offset for my tool (between nozzle and z switch) but I have also offset between my z switch/nozzle and the endstops (50mm) (x,y).?

G10 P0 X30 Y28.25 Z45 ; set tool 0 axis offsets without a P parameter?And how can I allowed the printer to move outside of my axis limits to collect the tools?

Do I have to define the size of the bed seperately or do I do this with axis minimum and maximum?

Thanks

R.G.; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Aug 02 2021 16:15:35 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M552 S1 P192.168.2.108 ; Wifi G4 S4 M574 C1 S3 M915 P1.2 C S0 F0 R1 ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.2 goes forwards M569 P0.4 S0 ; physical drive 0.2 goes forwards M569 P0.5 S0 ; physical drive 0.2 goes forwards M569 P1.0 S0 ; physical drive 0.2 goes forwards M569 P1.2 S0 ; physical drive 0.2 goes forwards M569 P121.0 S1 ; physical drive 121.0 goes forwards M569 P122.0 S1 ; physical drive 122.0 goes forwards M569 P123.0 S1 ; physical drive 123.0 goes forwards M584 X1.0 Y0.0:0.1 Z0.2:0.3:0.4:0.5 C1.2 E121.0:122.0:123.0 ; set drive mapping M350 X16 Y16 Z16 E16:16:16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z640.00 C91.022 E409.00:409.00:409.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 C3000 E3000.00:3000.00:3000.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z6000.00 C5000 E6000.00:6000.00:6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z300.00 C400 E250.00:250.00:250.00 ; set accelerations (mm/s^2) M906 X1300 Y1300 Z2500 C300 E1000:1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-10 Y-10 Z10 S1 ; set axis minima M208 X850 Y850 Z850 S0 ; set axis maxima ; Endstops M574 X2 S1 P"^io3.in" ; configure active-high endstop for high end on X via pin ^io3.in M574 Y2 S1 P"^io1.in" ; configure active-high endstop for high end on Y via pin ^io1.in M574 Z1 S1 P"^io2.in" ; configure active-high endstop for low end on Z via pin ^io2.in ; Z-Probe M558 P0 H-5 F300 T300 ; disable Z probe but set dive height, probe speed and travel speed M557 X10:10 Y10:10 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 R0.243 C586.2 D33.87 S1.00 V0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as PT1000 on pin 121.temp0 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set temperature limit for heater 1 to 250C M308 S2 P"122.temp0" Y"pt1000" R2200 ; configure sensor 2 as PT1000 on pin 122.temp0 M950 H2 C"122.out0" T2 ; create nozzle heater output on 122.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S250 ; set temperature limit for heater 2 to 250C M308 S3 P"123.temp0" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin 123.temp0 M950 H3 C"123.out0" T3 ; create nozzle heater output on 123.out0 and map it to sensor 3 M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H3 S250 ; set temperature limit for heater 3 to 250C ; Fans M950 F0 C"121.out1" Q500 ; create fan 0 on pin 121.out1 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"121.out2" Q500 ; create fan 1 on pin 121.out2 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"122.out1" Q500 ; create fan 2 on pin 122.out1 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"122.out2" Q500 ; create fan 3 on pin 122.out2 and set its frequency M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on M950 F4 C"123.out1" Q500 ; create fan 4 on pin 123.out1 and set its frequency M106 P4 S1 H-1 ; set fan 4 value. Thermostatic control is turned off M950 F5 C"123.out2" Q500 ; create fan 5 on pin 123.out2 and set its frequency M106 P5 S1 H3 T45 ; set fan 5 value. Thermostatic control is turned on M950 F6 C"out4" Q500 ; create fan 6 on pin out4 and set its frequency M106 P6 S1 H-1 ; set fan 6 value. Thermostatic control is turned off M950 F7 C"out5" Q500 ; create fan 7 on pin out5 and set its frequency M106 P7 S1 H T45 ; set fan 7 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X30 Y28.25 Z45 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F2 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 D2 H3 F4 ; define tool 2 G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

This post is deleted! -

@barbarossa-cologne, I tried to get stall detection working for the coupler motor. Unfortunately that motor gets quite hot during use, so stall detection parameters that work when the motor is cold don't work when it is hot.

-

@dc42 ok but that's not a problem in my case ?

Should I use different ways to home coupler?

Thanks

R.G. -

@dc42

I just wanna know about the offsets x and y. Coupler is working fine. Thanks a lot

R.G. -

@barbarossa-cologne said in TC coupler stall detection. custom.how?:

And how can I allowed the printer to move outside of my axis limits to collect the tools?

Do I have to define the size of the bed seperately or do I do this with axis minimum and maximum?If the print head can leave the printable area to pick up the tool you can either change the M208 limits such that the minima goes into the negative enough to allow for the full true range of motion while keeping the 0,0 point on the printable area. Or if it's on the positive side you could extend the maximum range temporarily. Or even just allow movement outside of the bounds temporarily.

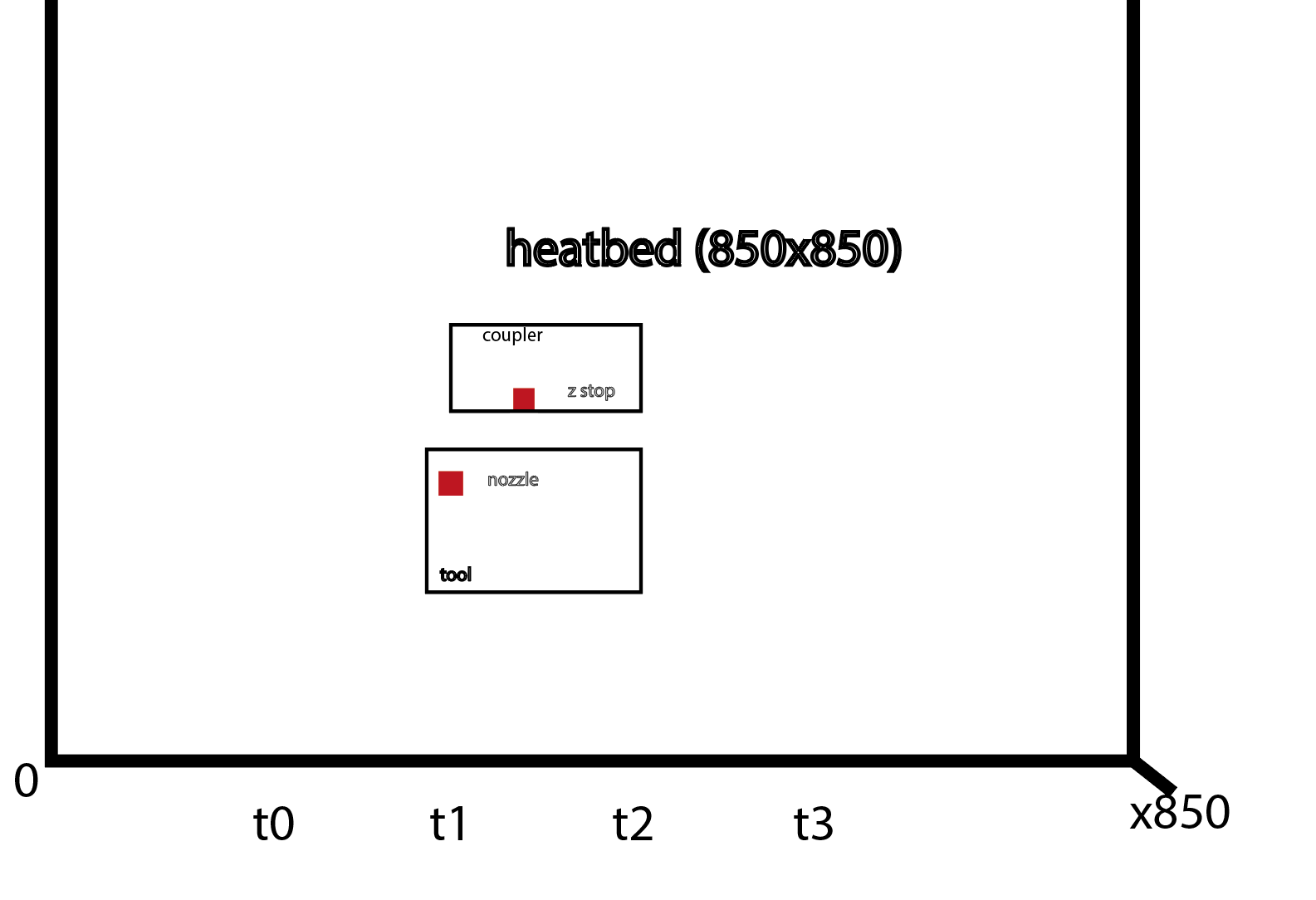

Can you show us a diagram illustrating your offsets?

-

I hope that is understandable...

that´s the last thing ( I hope) before start printing first time. thank you guys -

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X30 Y28.25 Z45 ; set tool 0 axis offsetsthis iy my tool offfset.

tool is in front of coupler (nearer to y0). So is it rigth to have a positiv number for the offset)?

Example; IN REAL. when x axis switch it at x100/y100 the nozzle is at x70/y71.75.

Thank you

R.G. -

-

@barbarossa-cologne

Problem solved!