Filament sensor

-

@deluxe-600 said in Filament sensor:

Error: Bad command: man.

M551 inman. ; Machine password

Put quotes around your password.

https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M551_Set_Password

Quotation marks around the password are mandatory in RRF3, but discretionary in earlier firmware versions.

@deluxe-600 said in Filament sensor:

Error: Z axis maximum must be greater than minimum

; Axis Limits

M208 X0 Y0 Z0 S0 ; Set axis minima

M208 X545 Y545 Z675 S0 ; Set axis maximaDo you notice anything wrong with your axis minima and maxima? You have S0 for both. Maximum should be S1.

https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M208_Set_axis_max_travel

@deluxe-600 said in Filament sensor:

G31 X0 Y0 Z0.9

You're missing the X Y offset for your probe.

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Measuring_Probe_X_Y_Offset

@deluxe-600 said in Filament sensor:

;Filament Runout Sensor M591 P1 C"e0stop" S1 D0 ; filament monitor connected to E0 endstop

Are you sure you're actually connected to the e0stop pin?

If you insert and remove the filament to trigger the endstop, does the endstop LED on the board go on and off?

Are you sure the switch triggers on high?M591 P1 or P2

1=simple sensor (high signal when filament present)

2=simple sensor (low signal when filament present)What kind of filament runout switch is it? Photo? Link?

@deluxe-600 said in Filament sensor:

I would like the sensor when it detects no filament to run the "filament-change.g" macro i have created for it.

I don't think this will be possible.

https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M591_RepRapFirmware_Num_3

The action on a filament error is to pause the print and advise you that there has been a filament error.

Filament-change.g is used by M600.

https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M600_Filament_change_pause

This command behaves like M226 except that if macro file filament-change.g exists in /sys on the SD card, it is run in preference to pause.g.

If you want the switch to do something specific, use this method described here https://duet3d.dozuki.com/Wiki/Connecting_and_configuring_filament-out_sensors#Section_Firmware_1_18_and_earlier

To make the firmware run a script when the filament runs out, use M581 to associate the endstop you chose with a "trigger". Trigger 0 is an emergency stop (probably not what you want), trigger 1 pauses the print (running pause.g), and otherwise trigger n runs the file triggern.g., which you can write yourself.

Finally, the trigger only happens when the endstop changes state. If you try to start a print with the filament out, the trigger won't happen. So add M582 to the start of your prints to check the filament state and run the trigger if there's no filament.

https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M581_RepRapFirmware_3_01_and_later

-

@phaedrux Thank you for the reply.

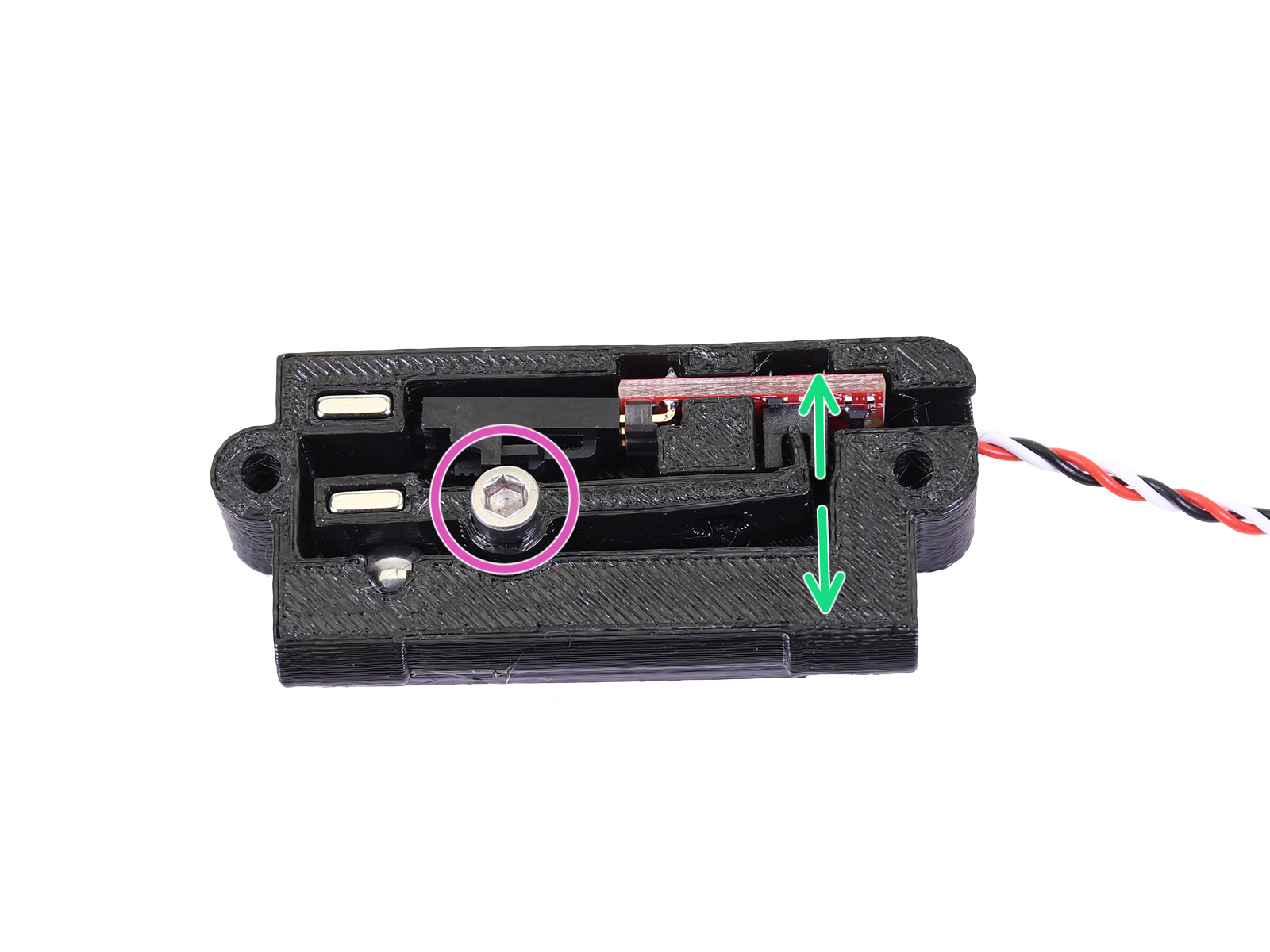

I am using filament sensor from Prusa MINI because i had it laying around.

Its a optical gate acting like a normal switch.

The sensor works as the print stops and the light on the board turns on.I understand i need the filament runout to send M600 command but i dont know how to do it.

-

@deluxe-600 in RRF3.3 if you configure a filament monitor using M591, when it reports no filament RRF will try to run filament-error#.g where # is the extruder number, or failing that filament-error.g. If neither of those is found then it runs pause.g.

-

@dc42

Sorry to hijack this thread, but I don't want to create a new one for this.

I've heard somewhere in the wiki that the filament sensor needs to be on the same board than the extruder it's watching to.

Is it still the case with 3.3+?

I'm about to switch to Duet 3 with 1LC toolboard, my filament sensor is outside the carriage, on the main board. -

@dc42

So if i understand it correctly. I need to find or make filament-error#.g and put the contents of

filament-change.g in it? Or how should i do it correctly?Or maybe delete the filament-error#.g or filament-error.g for it to run pause.g?

Best would be if i could somehow run filament-change.g as a result of no fillament trigger.

-

@deluxe-600 just copy filament-change.g to filament-error.g; or have filament-error.g call filament-change.g using M98.

-

@dc42 Thanks, i will try that and let you know.

-

@kipk said in Filament sensor:

@dc42

Sorry to hijack this thread, but I don't want to create a new one for this.

I've heard somewhere in the wiki that the filament sensor needs to be on the same board than the extruder it's watching to.

Is it still the case with 3.3+?

I'm about to switch to Duet 3 with 1LC toolboard, my filament sensor is outside the carriage, on the main board.I have a very similar situation. I'm about to add a filament sensor and have two questions:

-

The question above that was already asked, must the detector be connected to the same (tool) board that's running the extruder?

-

If I'm using a tool board, in the M591 configuration, Is the correct parameter "D121.0" since the extruder is run from the tool board, or just "E0"?

Thanks

-

-

@dc42 After a bit of trial and error i figured it out .

For some reason adding just M98 P"pause.g" in the filament-error does nothing.

So i just copied everything from pause.g to filament-error.g but then i wanted the tool to be put in stand by. After a few tries i figured out it needs to be writen is specific order to work.

So here is my final version of filament-error.g that actualy does what its suposed to.G10 P0 R20 ; Set standby temp of tool 0 to 20*

M83 ; relative extruder moves

G1 E-50 F2000 ; retract 10mm of filament

G91 ; relative moves

G1 Z5 F500 ; raise nozzle 5mm

G90 ; absolute moves

G1 X20 Y525 F6000 ; go to X=20 Y=525

T-1 ; Deselect toolThank you for the help guys, have a great day.

-

@kb58 said in Filament sensor:

I have a very similar situation. I'm about to add a filament sensor and have two questions:

The question above that was already asked, must the detector be connected to the same (tool) board that's running the extruder?

If I'm using a tool board, in the M591 configuration, Is the correct parameter "D121.0" since the extruder is run from the tool board, or just "E0"?

I know, the thread is a little bit old. But I had the same questions, nobody has been answered and maybe it will help other users with Filament sensor and 1LC...

- Yes, it have to...

- D0 is ok. Here's my config.

; Filament sensor (Duet) M591 D0 P3 C"121.io1.in" S1 R70:130 L24.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length M591 D0 ; display filament sensor parameters for extruder drive 0