Too late to tell me to buy one - I enjoy learning new things and that included building a printer from scratch. It's a pretty decent learning curve, but having built two cars from scratch, I'm used to doing things the hard way - much more rewarding.

kb58

@kb58

Built two scratch-built cars (www.kimini.com and www.midlana.com). Now venturing into other garage hobbies.

Best posts made by kb58

-

RE: First 3-d printerposted in 3D Printing General Chat

-

RE: Might have killed my Duetposted in Duet Hardware and wiring

You can try washing the board in distilled water, then putting it in a warm area to dry. That said, were any changes made to the printer before the failure? It's highly unlikely that Dimafix is causing the problem, but try the above.

-

RE: Odd mechanical failureposted in Off Topic

A few more possibilities:

- Is the printer in a heated chamber? Even if it's not, maybe the bed warmed the Delrin enough to expand it away from bearings?

- How much of a press fit were the bearings?

- does Delrin "cold flow" like Nylon, causing them to loosen?

- How do you know that the shafts are truly 90-deg to the belt path?

- How lose/tight are the bearing hubs on the bolt?

- Do the bearings spin freely, or could they be binding?

- Related, maybe the bearings bind as they warm up?

-

RE: Is there a cure for embarrassing oozing?posted in Tuning and tweaking

@jens55 Sometimes that works and sometimes it doesn't. If the oozed bit breaks off clean onto the bed, no problem. It can be more of a problem if it rolls around and sticks itself to the side of the nozzle cone. Afterwards, during the print, there can be a lump of melted filament right near the nozzle, risking dragging it through the wet extrusion.

I increased retract slightly and watched it. Somewhat surprisingly it made no difference. The nozzle comes to the front of the bed, extrudes XXmm, extruder stops, retracts, and that hanging bit is removed. At that point, it's "Press OK to Start", but then when I look back, there's already maybe 5mm hanging from the nozzle. Wipe that off, go to press OK, look at nozzle, and there's another 4mm. So, I just waited and watched, and over the next minute or so, maybe 50mm of extruded plastic had slowly wormed its way out of the nozzle.

As an experiment, I'll increase retract to something huge, like 5mm, to guarantee that the filament really isn't pushing at all. While I doubt that gravity is enough to allow the molten filament to pass through the nozzle, we'll see. It is a direct drive BondTech LGX, so there should be no Bowden tube antics going on. -

RE: First 3-d printerposted in 3D Printing General Chat

@jens55 I had a few printers on my short list, but after digging deeper, there was a number of comments that "After I replaced the hotend, extruder, Bowden tube, fans, display, and controller, my Brand X is awesome!" My reasoning then switched to "well if a printer only becomes 'awesome' after replacing everything, then I'll make one from scratch." And yes, it can get pretty expensive...

-

RE: Variable "already exists"posted in Gcode meta commands

@donstauffer said in Variable "already exists":

@fcwilt The files are there, including config.g, which shows zero bytes!

Interesting... I had this exact thing happen several weeks ago and am pretty sure it was due to a corrupted write. I had to delete config.g and renamed config.bak as config.g. The other way was to remove the SD drive and fix it in the PC - I always keep duplicates of the SD files on the PC for just this sort of reason.

-

RE: 3HC pins issue (io2.out) (RRF 3.3)posted in Duet Hardware and wiring

Did you enable usage (whether it's present or not) of a PanelDue? If so, the firmware assumes that it's connected to io0.

If you want more detailed answers, please provide your config.g file, pasted in using the </> tag above the Reply window.

-

RE: Mesh bed leveling G29 issuesposted in Tuning and tweaking

One thing I never see suggested is that if a user suspects that the bed profile is not being applied to a print, is to try this:

- Tape something like a strip of thick construction paper across the bed.

- Do a bed profile

- View the bed profile, and it should clearly show the "lump" in the bed.

- Remove the paper

- Do a fake print (no filament) that crosses that area and watch the Z clearance. When it gets to where the paper was, you should see the nozzle move away from the bed as it approaches.

-

RE: 3 Z axis and homingposted in General Discussion

I'll look into using G1 H1. Keep in mind that I gathered the information on creating these files from multiple sources. Some of it hasn't been tested yet and is no doubt completely wrong, but for the purposes of this thread, I'll stick to just Z homing.

What you're describing is my end goal, to have the three steppers home to the switches, then do a three point probe to do fine leveling. As mentioned, I very likely have lines of code that are either wrong or have no business being there, but I'm slowly coming up on the learning curve for all of this.

-

RE: Duet 2 wifi - 3.3v failureposted in Duet Hardware and wiring

An easy test is to unplug everything except power, power up the board, and see if the 3.3V rail drops again. If it stays good, start plugging in things one at a time (except steppers) until you find the troublemaker. If it remains bad, then yes, it's something on the board itself.

Latest posts made by kb58

-

RE: Problem 5v on duet 3 mini 5 +posted in Duet Hardware and wiring

@azariel I don't know about that specific board, but on other Duet boards, there is an on-board jumper that connect 5V to the board. The jumper is removed when it's powered by a USB port. Is the jumper in place?

If it was never removed, it's possible that the USB 5V backfed into the onboard 5V regulator and damaged it.

-

RE: Unexpected resetsposted in Using Duet Controllers

@aitor Does it happen often enough that testing different configurations could help, or its it so infrequent you're just curious what's going on?

You can start by carefully checking all the power connections. One of the best and easiest tests is the "wiggle test." With everything powered up and running, wiggle all the connections and see what happens, which should be nothing. Another test (hence the question above), is to unplug everything not necessary to have the machine in its idle condition (power, display, and/or Ethernet), and let it sit and see if it resets.

If nothing is found, maybe consider replacing the power supply.

-

RE: Bed heater crashing Duet WiFi at set pointposted in Duet Hardware and wiring

@adarack Glad that it's fixed. My money is on a poor connection such that as it approaches the temperature setpoint and shuts off the heater, there's a good size voltage spike that resetting the board. If it starts doing it again, I'd suspect the power supply, Meanwell or not.

-

RE: Bondtech LGX Wiringposted in Duet Hardware and wiring

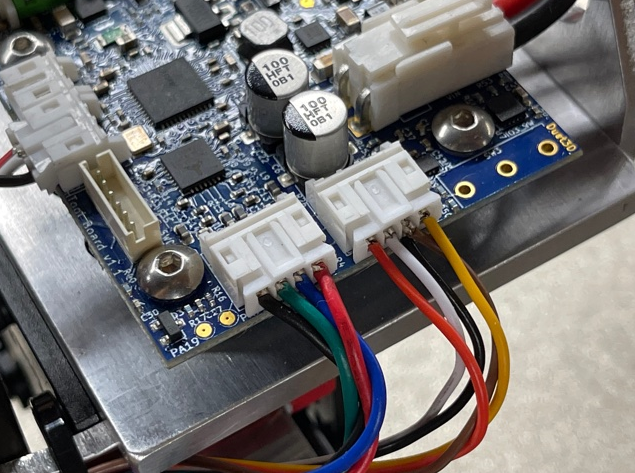

@leobg Your blue and red wires are reversed at the stepper in comparison with mine.

-

RE: Bondtech LGX Wiringposted in Duet Hardware and wiring

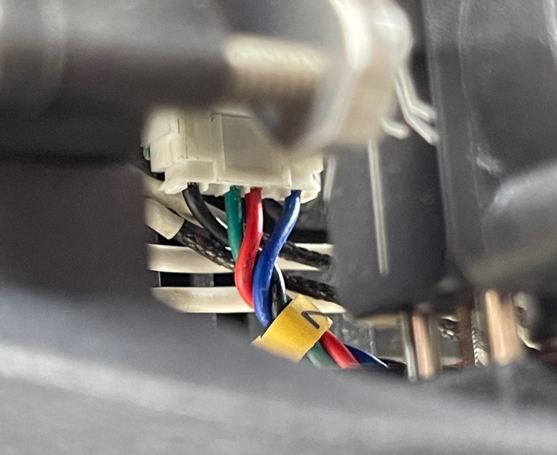

@nightlonk42 Here's how it's wired at the stepper end. Note that this is as viewed from the front of the extruder, and also that the stepper has been rotated so that its connector is on the bottom.

-

RE: Bondtech LGX Wiringposted in Duet Hardware and wiring

@nightlonk42 Those colors match how I have mine wired at the toolboard end, but at the stepper end, manufacturers can be a bit arbitrary. Honestly, just try a few permutations, as it'll take much less time doing that than waiting around for answers that may not be appropriate for your stepper.

Also, double check how you configured the stepper - having that wrong could do it as well. Someone's bound to ask for you to list out your config.g...

-

RE: Might have killed my Duetposted in Duet Hardware and wiring

You can try washing the board in distilled water, then putting it in a warm area to dry. That said, were any changes made to the printer before the failure? It's highly unlikely that Dimafix is causing the problem, but try the above.

-

RE: stop movement when endstop is triggeredposted in Tuning and tweaking

@fcwilt Fredrick, I've seen posts by some advanced users where they're directly accessing the Duet firmware. Are there not global flags for X, Y, and Z homing? If so, it seems like these flags could be could be temporarily loaded with "Homed" and the extruder moved as desired. Or are these flags unavailable?

-

RE: Slow down before endstop?posted in CNC

@thekm Understood, but it does argue for position feedback, so that speed can be slowed down smoothly and still end up where you want it.

-

RE: Slow down before endstop?posted in CNC

I just realized the flaw in my suggestion: If it's got enough momentum and bulk, it'll still coast to a stop even when the steppers are trying to stop it after hitting the switch, losing its known position.

This seems to make a case for stepper "servos" with positional feedback, or go for the full Monty and move to true servos.