Duet 3 Mini 5+ for a Voron V2.4?

-

@zapta that looks good to me, assuming TMC2209 drivers are adequate to power the motors in the Voron, and you are happy to fan-cool the Duet.

Have you considered using a tool board mounted on the print head? This would greatly reduce the amount of wiring to the print head, and version 1.1 tool board includes the accelerometer.

-

@zapta

A friend is building a 2.4. Out of mind that is exactly the same HW.

He will use a TB V1.1 and has designed an holder for the Afterburner.

I recommended not to upgrade the existing Duet Wifi with a Duex but to replace it with the Mini + TB.

This got a bit more expensive but as @dc42 mentioned much easier to wire and more up to date.

I get in trouble when this does not work in the Voron....

For me it works in a HEVO with smaller motors and Bltouch... -

Thanks @dc42. I considered the tool board idea but it may be too big to fit nicely. The Voron is a complete at tight design with great focus on aesthetics.

I presume that the toolboard would be OK with the enclosed and normal than usual Voron chamber. As for the TMC2209, this is also what the stock Voron recommend so I presume they are all the same or does the heatsinks that come with the Chinese TMC2209 makes them more heat tolerant?

I presume that the toolboard would be OK with the enclosed and normal than usual Voron chamber. As for the TMC2209, this is also what the stock Voron recommend so I presume they are all the same or does the heatsinks that come with the Chinese TMC2209 makes them more heat tolerant?As for fan cooling of the Mini 5+, is there a simple way to determine if it's sufficient? E.g. MCU temperature? Anything else? (The Voron 2.4 electronics is below the printing chamber and has a few fans on the skirt.

@DIY-O-Sphere, yes, I plan to get a new Mini 5+ plus two drivers plugin module. This will provide better RGB LEDs support over the Duet 2

vs

-

@zapta

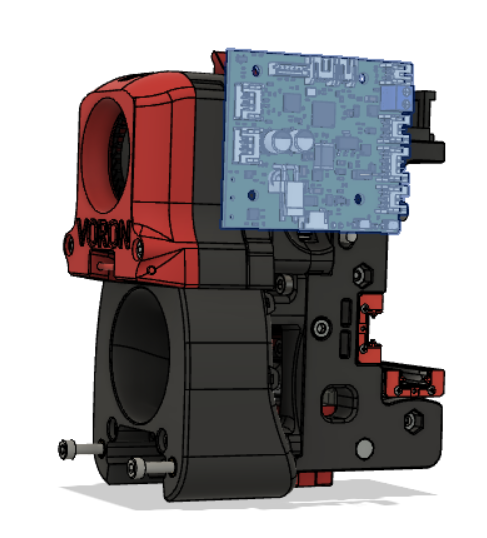

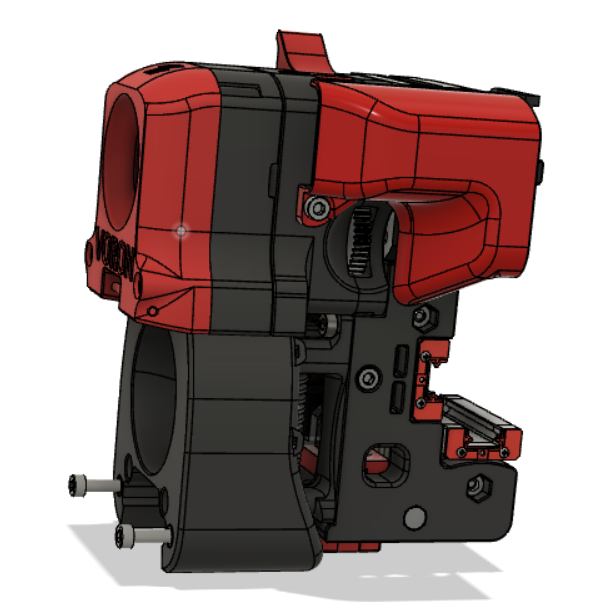

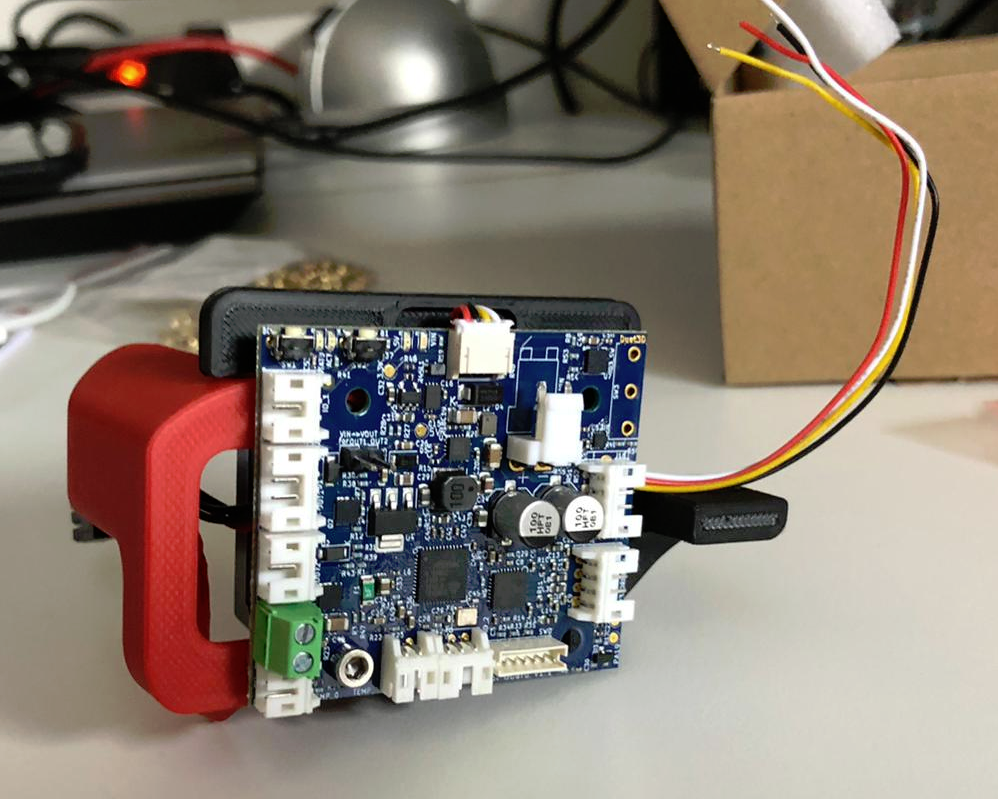

Other approach...I am alowed to show some pictures...not yet tested

Without inserts

Perhaps a little more distance needs to be provided for the cooling.

We will get to know it..... -

@diy-o-sphere, that's a nice location. Would be nice to redesign the toolboard for a perfect fit (dual side components, consolidating connects, shape, location of mounting holes, etc).

BTW, this is a custom distribution PCB, no components, just connectors. It may come with its own cover design, not sure.

https://github.com/hartk1213/Voron-Hardware/tree/hartk1213/Voron-Hardware/Afterburner_Toolhead_PCB

-

@zapta

No input shaping...or even more wires for LIS3DH accelerometer.

And the wiring with CAN is so brilliant that I would never do it any other way again.... -

@diy-o-sphere said in Duet 3 Mini 5+ for a Voron V2.4?:

No input shaping.

No way to connect an accelerometer to a Mini 5+ for input shaper calibration? That would be a show stopper for me.

-

@zapta said in Duet 3 Mini 5+ for a Voron V2.4?:

No way to connect an accelerometer to a Mini 5+ for input shaper calibration?

Mini5+ will work with input shaping. I'm not sure what @DIY-O-Sphere was meaning. Perhaps he meant that if you didn't go with a toolboard 1.1 you'd need to add more wires for the accelerometer as well to get the input shaping.

-

@phaedrux

You got it...

-

@phaedrux said in Duet 3 Mini 5+ for a Voron V2.4?:

Perhaps he meant that if you didn't go with a toolboard 1.1 you'd need to add more wires for the accelerometer as well to get the input shaping.

Thanks @Phaedrux. Is it reasonable to mount the accelerometer temporarily for calibration or is a strong argument for having the accelerometer mounted all the time?

-

@zapta said in Duet 3 Mini 5+ for a Voron V2.4?:

Is it reasonable to mount the accelerometer temporarily for calibration or is a strong argument for having the accelerometer mounted all the time?

My understanding is that it's only required for the initial measurements, so could be removed. But that's not to say there won't be some future benefit to having real time accelerometer data.

-

@phaedrux, thanks.

-

I like the 50w heaters personally. Super fast heat up times. I used to kill one about every 100hrs at 350-380c until I spent a few extra bucks and got one from Slice. If your printing 250 and below the Slice or amazon/Ebay sourced versions will probably last forever.

-

@3dpmicro, last time I run PID tuning I got a warning message about a very high max temperature which cause me to be more humble when selecting heater wattage

In my current printer I have a 40W 'only nozzle heater and it still heats faster than the bed.

BTW, I place an order for a Mini5+ and a dual drivers module, so will see how it will go. I am quiet excited about having only a small Wifi board in the Voron, dropping the SBC and the auxiliary 5V power supply. Need to see where to fit that external antenna. Keeping the clean box shape of the frame makes it easier to place it in any orientation while working on it.

-

@zapta said in Duet 3 Mini 5+ for a Voron V2.4?:

@3dpmicro, last time I run PID tuning I got a warning message about a very high max temperature which cause me to be more humble when selecting heater wattage

In my current printer I have a 40W 'only nozzle heater and it still heats faster than the bed.

Cant argue with the desire to be safe

-

@diy-o-sphere Do you have the files for that back-side mount that you'd be willing to share? I'm getting ready to build my Voron 2.4 and I'm adding as many bells and whistles as I can

-

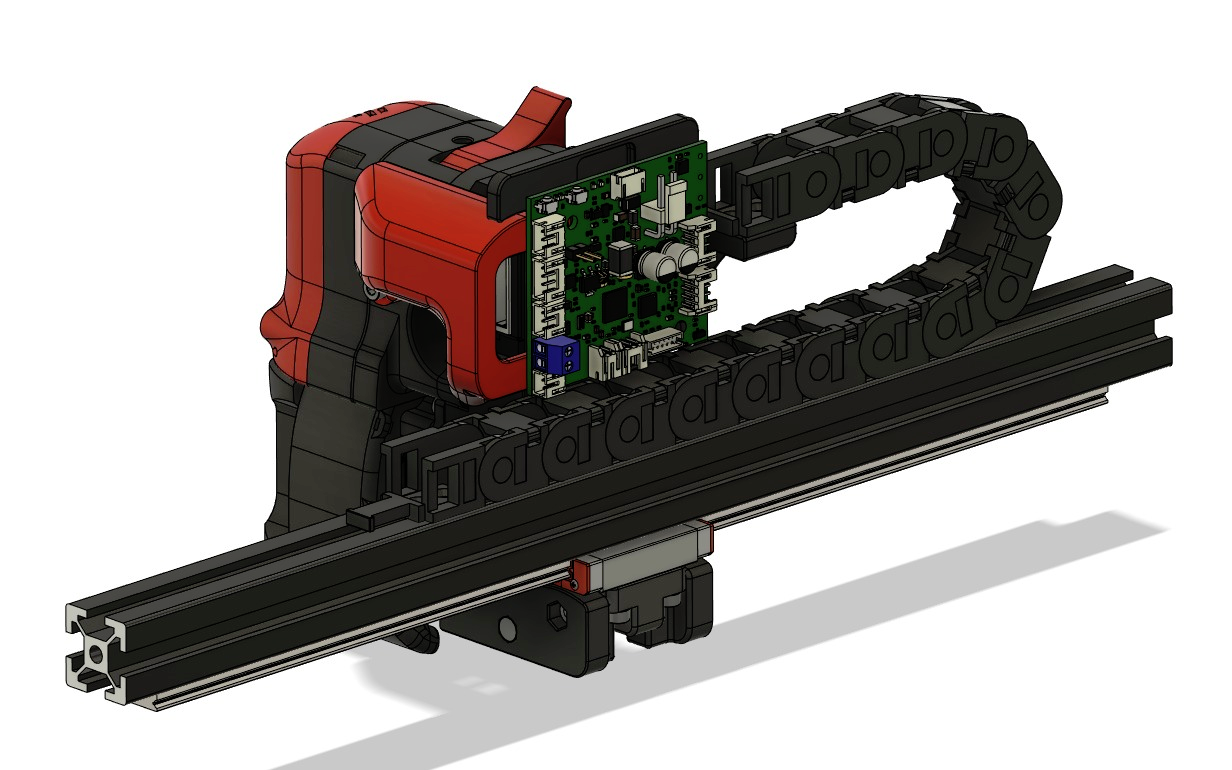

At the moment, my friend is still struggling with the connection of the energy chain. He is currently adjusting the position and size of the chain so as not to lose any space in the x-direction. As soon as this works he will share them.

-

Any issue with the Tool Board electronics operating in the enclosed and hotter than usual Voron V2.4 chamber?

-

@zapta At 60 degrees in the chamber, it works for me without any problems

-

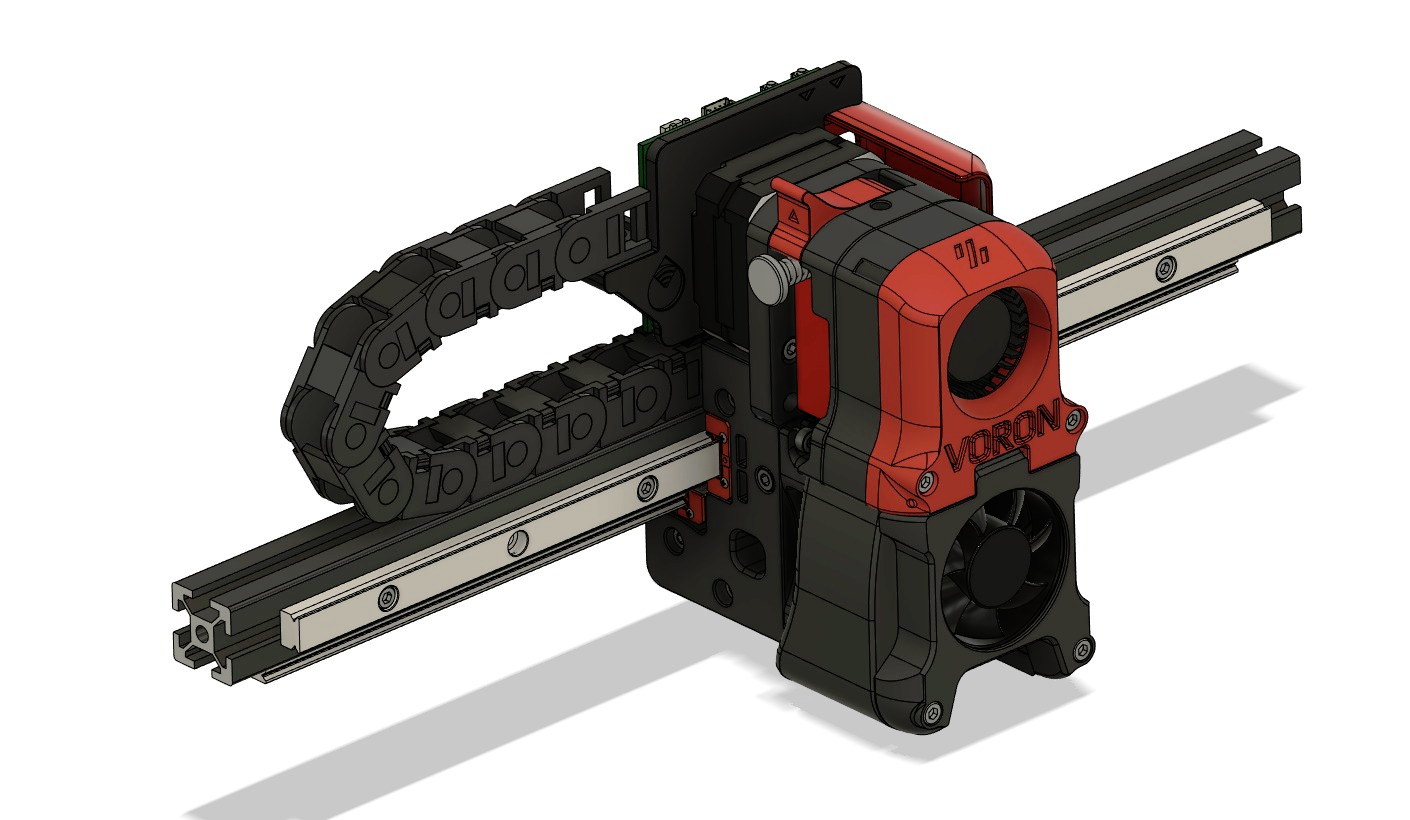

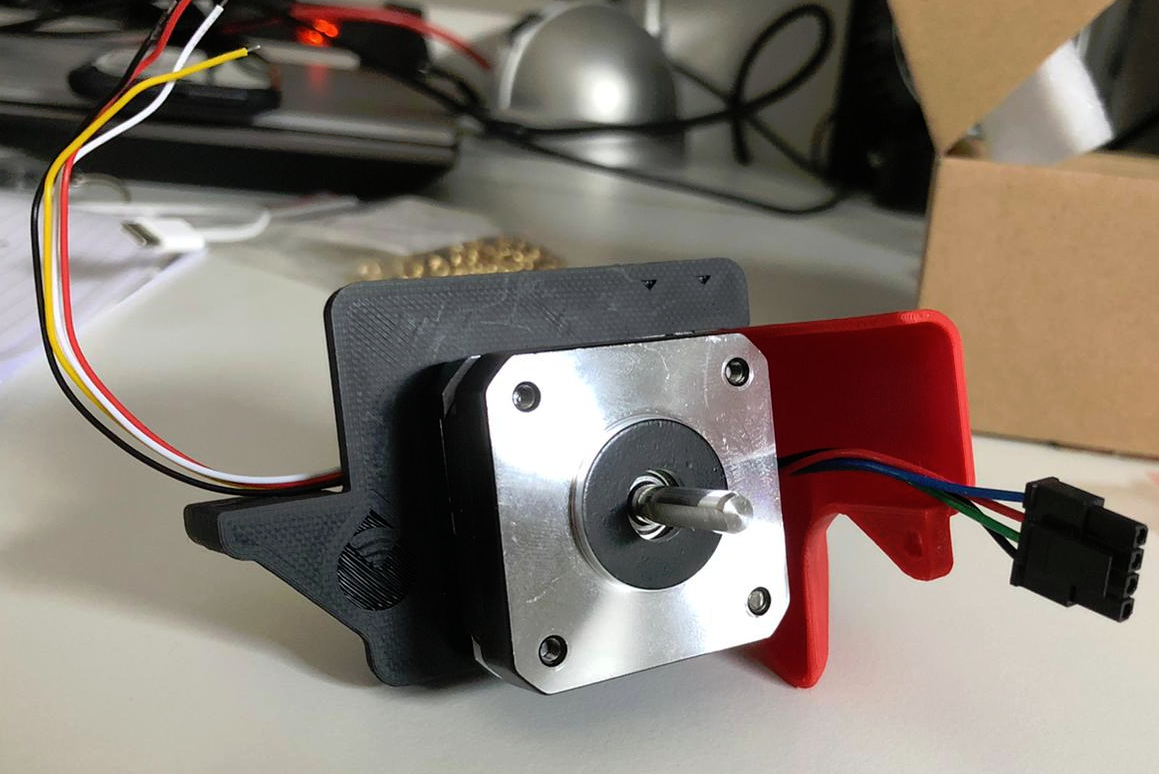

@zapta This is my solution with the Galileo variant of the clockwork extruder