"waves" on rounded prints

-

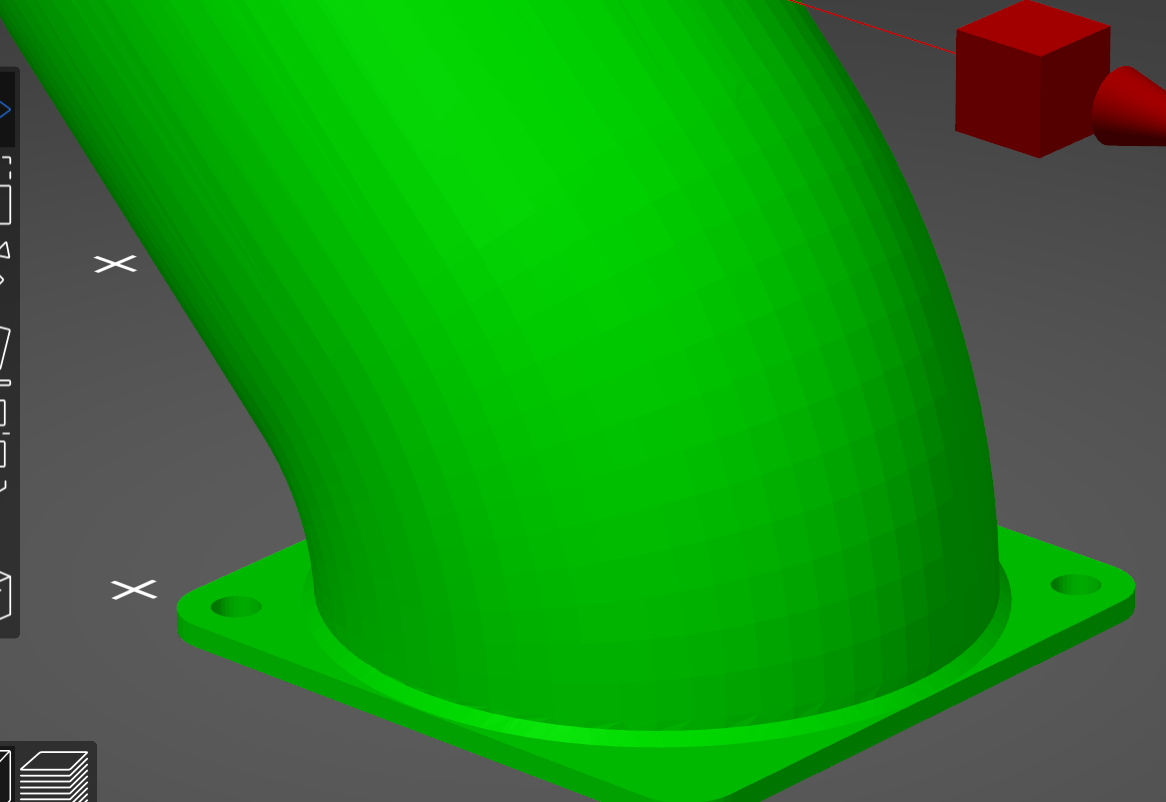

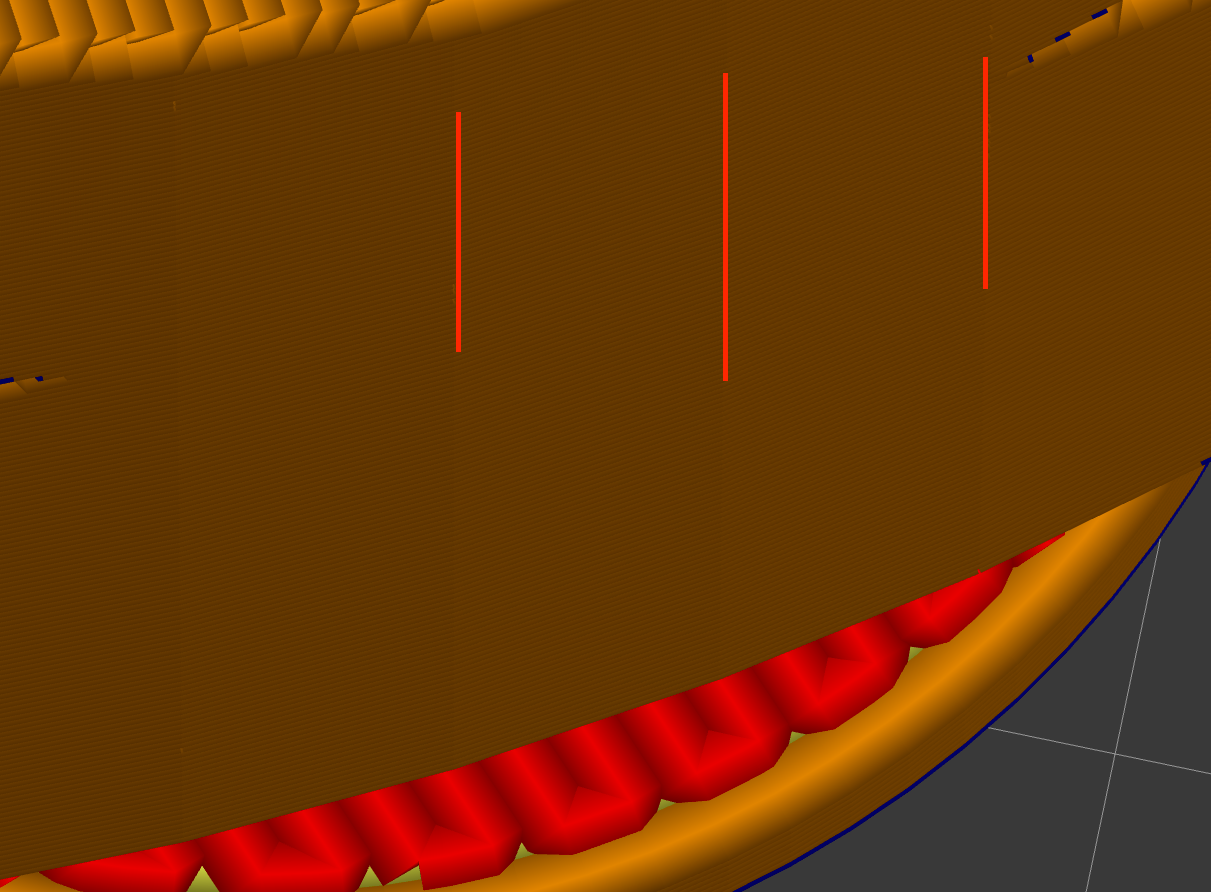

Hi. I have been having this issue nd I cant find the problem: I have a custom made printer, hbot. I have been running it with latest stable firmware version. The print are really high quality from the point of view os extrusion and layer aligments. But when I print rounded shapes, the "waves" you can see in the pictures appear. Straight lines are perfect, this shows up only in rounded paths.

It is not the infill, since the picture I post here has no infill at all. And what it makes me post here is because I have just noticed a pattend: the wave vertixes match the poligons on the STL as you can see in the pictures (I think so). The exact same STL is printed in Marlin, shows a perfect rounded surface. So this is why Im suspecting something is wronng on my duet firmware configuration?

I have attached also mu config.g file

I thank in advance the help.

I have already done the usual checks: everuthing is parallel, there is nothing loose or backlash present, in fact I tried to tighten the bels even more and the problem gets worst. If I loose the bels a lot to a point that I know It cant be right to have the belts that loose, the problem dimishes a little.

Any ideas?

-

-

@o_lampe jajajaja I guess it is a good news for me but it doesnt feel like that jajajaja

The M669 option you talk about, seems to e only available for 3.3 version. My problem now is to upgrade but also can you elaborate on how to use these options and how they work? Im still confused on how this behaviour of my printer is "good because is accurate"

-

If the artefacts you are seeing seem to be related to the STL have you tried increasing the resolution of the STL to see if that improves things?

-

I got this issue this week. Printer was like moving/extruding in wavy pattern around circles with unusual noise.

It was my extruder jerk/acc that was way too high.

Lowering it from 1000 to 300 srk and 2000 to 600 acc solved theproblem ( Orbiter ) -

The quality setting of the exported model isn't set to "Highest".

You may want to try the "curve smoothing" feature of SuperSlicer.

-

@argo is the speed constant when it prints those curves? If it isn't, that could be caused by the XY jerk limit being set to low, and it could accentuate the facets in the STL file.

-

If the model is poorly exported and If I forgot to enable the "curve smoothing" feature in SuperSlicer, it's more or less a "corner" to "corner" transition for the printer (RRF) with acceleration and deacceleration for every "corner". So the speed is not constant and it has to respect the set jerk speed.

The interesting bit though is that @Tinchus mentions that the object is perfectly round printed with Marlin. Maybe Marlin's junction deviation has some kind of planner built in that assumes it's a round object and thereby prints it round? Then it would be interesting to know with what thresholds Marlin is working with so it does not smoothes out edges that are wanted.

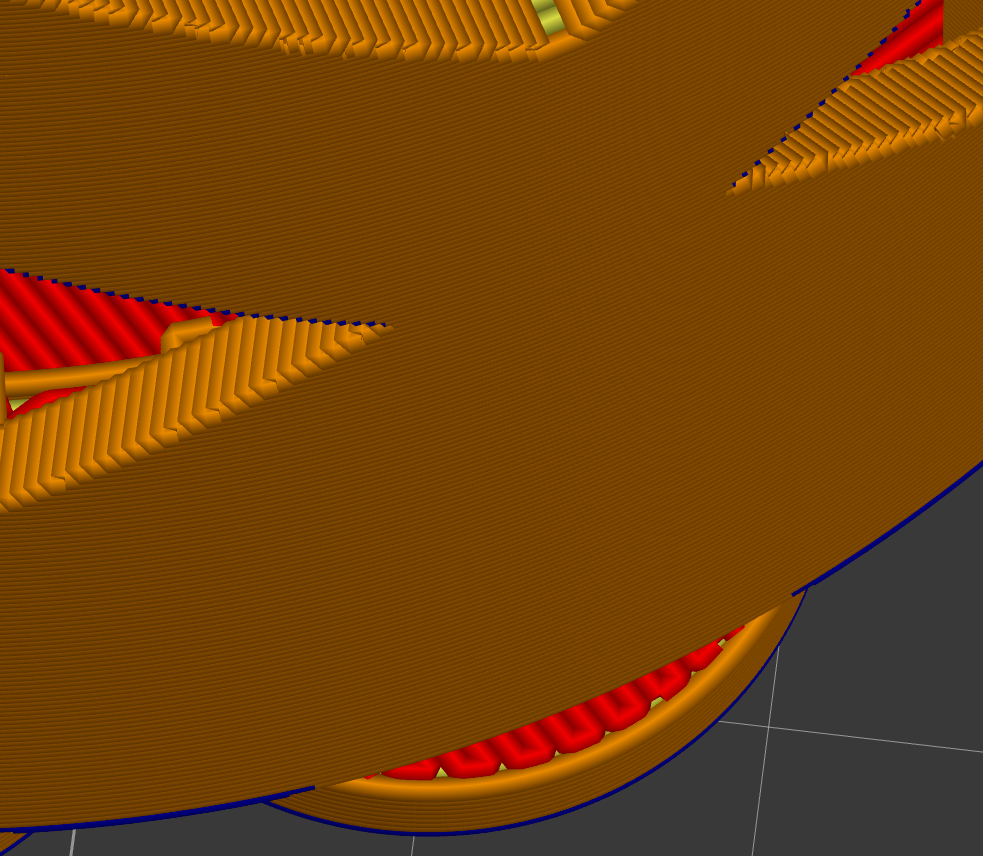

Right now every printer in the house is running RRF (+1 Klipper) so I can't test that.Here is an example of curve smoothing within the slicer software. Advantage is that STLs downloaded from the internet or exported from CAD can be rather small because the additional information is added within the slicer software.

Sliced without curve smoothing, F360 export setting "medium":

And with curve smoothing enabled:

-

@argo said in "waves" on rounded prints:

If the model is poorly exported and If I forgot to enable the "curve smoothing" feature in SuperSlicer, it's more or less a "corner" to "corner" transition for the printer (RRF) with acceleration and deacceleration for every "corner". So the speed is not constant and it has to respect the set jerk speed.

Increasing the allowed XY jerk will avoid that. Alternatively, export the model to STL with finer resolution.

-

@tinchus said in "waves" on rounded prints:

@o_lampe jajajaja I guess it is a good news for me but it doesnt feel like that jajajaja

The M669 option you talk about, seems to e only available for 3.3 version. My problem now is to upgrade but also can you elaborate on how to use these options and how they work? Im still confused on how this behaviour of my printer is "good because is accurate"

I tried it myself with a 5:1 scaled up cylinder (very coarse now) and played with different numbers. They don't make a difference.

As others have stated before, you have to refine the STL export and or use smoothing options (if available) -

@dc42 I thought about this, but my config it is using 1200 of jerk and 6500 of acceleration.

In the extruder I have set 500 as jerk and max speed of 2400 mm/min, wich I could say never is reached and that value os only there just to have a high speed when I feed the printer at the beggining of the new spool. My extruder is a nema17 motor (pancake) attached to a bondtech. The motor of extruder is ore than capable to suppor that jer/accel/speed or do you think I shpould lower these values

-

@argo What values exactly are you using with curve smoothing in superslicer?

-

Precision: 0.02mm

Angle detection 120° each

Cutoff: 4-6mm (depending on how bad the exported model is) -

@argo Update on this issue: using the curve smoothing solves the problem. Also, I made a copy of the original STL using solidworks, exported it as STL but using max quality for the STL and also the print came out PERFECT.

So all this issue is about the STL quality

Thanks all for the help -

Glad it works. Curve smoothing is a life safer for downloaded STLs. Those files are often low res because of size.

-

I'll have to try out curve smoothing in super slicer. I use the high quality preset in Fusion360 but I still see some STL facet artifacts.