Jerk Control M566

-

@kroybal well there's your problem...

M906 X700 Y700 Z700 E700:700 U700700ma seems a very low motor current to be running (particularly if you've got a big heavy gantry!).

You really ought to find out what motors you've got and what their rated current is. Then set the motor currents to 70-80% of that. -

@kroybal said in Jerk Control M566:

............, but I am pretty sure it lies in settings.

.........................

note: even using the same settings that have worked for me prior do not work for me now?...............Those two statements are contradictory so only one of them can be true.

What sort of moving mass do you think you have? Also, why do you think the solution lies in reducing the instantaneous speed change threshold to a value where segmented arcs would be printed at less than 6mm/sec?

-

700ma seems a very low motor current to be running (particularly if you've got a big heavy gantry!).

You really ought to find out what motors you've got and what their rated current is. Then set the motor currents to 70-80% of that.Sure thing. I do not know for myself, but the person that sold my company the printer told us that the motors were 800mA rated. It is a heavy gantry but each axis has 2 motors connected. I dropped my x-axis and y-axis motors down to 600mA and they're working great still. My Z-axis appears to have larger motors for each lead screw so I left it at the 700mA. I will look deeper into it, though the decision isn't solely mine to make.

-

@deckingman said in Jerk Control M566:

@kroybal said in Jerk Control M566:

............, but I am pretty sure it lies in settings.

.........................

note: even using the same settings that have worked for me prior do not work for me now?...............Those two statements are contradictory so only one of them can be true.

What sort of moving mass do you think you have? Also, why do you think the solution lies in reducing the instantaneous speed change threshold to a value where segmented arcs would be printed at less than 6mm/sec?

I felt looking into jerk control could be a possible fix due to the fact that one of my curved prints were very noticeably line segments even more so than you would like coming from a large format printer. My analogy would be that the parts appeared like graphics in a nintendo 64 video game, but we would like to see at the least 2001 Xbox graphics.

Edit: increasing jerk control parameters consistently resulted in skipped steps and huge and/or subtle layer shifts.

-

@kroybal said in Jerk Control M566:

I felt looking into jerk control could be a possible fix due to the fact that one of my curved prints were very noticeably line segments even more so than you would like coming from a large format printer. My analogy would be that the parts appeared like graphics in a nintendo 64 video game, but we would like to see at the least 2001 Xbox graphics.

@kroybal If you model has the line segments(ie a low resolution model) modifying the jerk settings will not make those go away.

That can only be fixed by using a high res model.

-

@kroybal said in Jerk Control M566:

I do not know for myself, but the person that sold my company the printer told us that the motors were 800mA rated.

That may be the case but it would be good to know the specs of the motors if possible. There are some truly awful motors for 3d printers being used in 3d printers because the designers just didn't know any better.

You can experiment with higher currents and monitor the temps. Anything up to 80c over a long duration is probably alright. If you're able to increase the current and the temp stays well below that then the motors were likely rated for much higher.

Getting a model number off the motor would be ideal.

-

@kroybal said in Jerk Control M566:

... one of my curved prints were very noticeably line segments even more so than you would like coming from a large format printer.

That is almost certainly caused by how the model is described in the STL file. In STL, curves are represented as segments. It's up to the person who designed or exported the model to STL to decide how small those segments are.

-

I've noticed that with very low "jerk" rates, the facets of the model are much more visible. This is likely due to the extrudate "bulging" as the print head slows down to the jerk rate. In the case of OP, this is 0.1 mm/sec.

This is why I'm very glad to see progress being made soon towards a better alternative for instantaneous speed changes. The limitation is significant in preventing faster printing around curves, while slowing down enough on sharp corners.

-

@Phaedrux I have been incrementing the currents up and monitoring their temperatures (~50C in 40C hot chamber). I have them set to 1A but looking up lists of motors that they might be suggest they could have a rated current of around 2.8A. I will remain conserved with it but before I take the thing apart I called in a request for the support team to see if I can obtain those part numbers without having to take apart the water cooling and gantry.

-

@dc42 said in Jerk Control M566:

@kroybal said in Jerk Control M566:

... one of my curved prints were very noticeably line segments even more so than you would like coming from a large format printer.

That is almost certainly caused by how the model is described in the STL file. In STL, curves are represented as segments. It's up to the person who designed or exported the model to STL to decide how small those segments are.

Interesting, I sort of played around with that idea but I have results that do not support that statement:

above are images of the same STL file printed on different printers using the same parameters in Simplify3D. The difference is night and day. There is visible segments and layer shifting. I am frustrated with how difficult this has been to diagnose what could cause such lackluster quality, but I am determined to get to the bottom of this.

-

@bot said in Jerk Control M566:

I've noticed that with very low "jerk" rates, the facets of the model are much more visible. This is likely due to the extrudate "bulging" as the print head slows down to the jerk rate. In the case of OP, this is 0.1 mm/sec.

I think that could be the case, consider the images in my response to @dc42

-

Can you provide some photos and details on the printer itself so we can see what you're dealing with? Maybe a video of it printing?

-

@Phaedrux Sure, I am running an Aon-M1 legacy printer. Just for sake of preparation does this forum allow videos or is it best to upload to to YouTube first?

-

MP4 should work but there are size limits. So putting a video on YouTube or something would probably be best.

-

EDIT:

@Phaedrux okay, so I caught it subtly layer shifting as it tends to do. I will try to upload the video after lunch and give you an example. Usually after the bottom solid layers it starts gradually shifting, an analogy would be if you place a book flat on a table and press down firmly on the cover and apply sheer force to it causing the pages (in our case layers) to skew. In theory after catching a layer shift pausing the print and homing the toolhead should fix it (if it were to have mechanically skipped a step). Instead it typically returns to the same layer-shifted location as before and resuming the print resumes the layer shifting. This time it didn't even do that. Mind you, it has more amperage, higher jerk rates and accelerations this time around. In the video it resumed the print with no precision. Leading me to believe low acc. and low jerk rates are our better bet.stay tuned.

-

At my eyes it seems that with so low jerk values the printhead is stopping at every STL triangle and the extruder is overextruding there due to low speed and higher temperature on the already layed plastic. I would try to increase the jerk and print speed. These result are impossibile to be caused but too high jerk. You can clearely see the mesh triangles and still the model seems to be really low on poly count.

Just my 2 cents.Note: My jerk is at 900 in a medium size corexy with directdrive extruder so i think your values are really too low also with taking account of a heavy toolhead.

-

@MikeS The problem there is too much jerk (>10mm/min) causes awful results, too little jerk (6mm/min) results in blemishes.

I am in the process of putting together a video for @Phaedrux and anyone else kind enough to assist with diagnostics I may have to setup a YT account to do so.

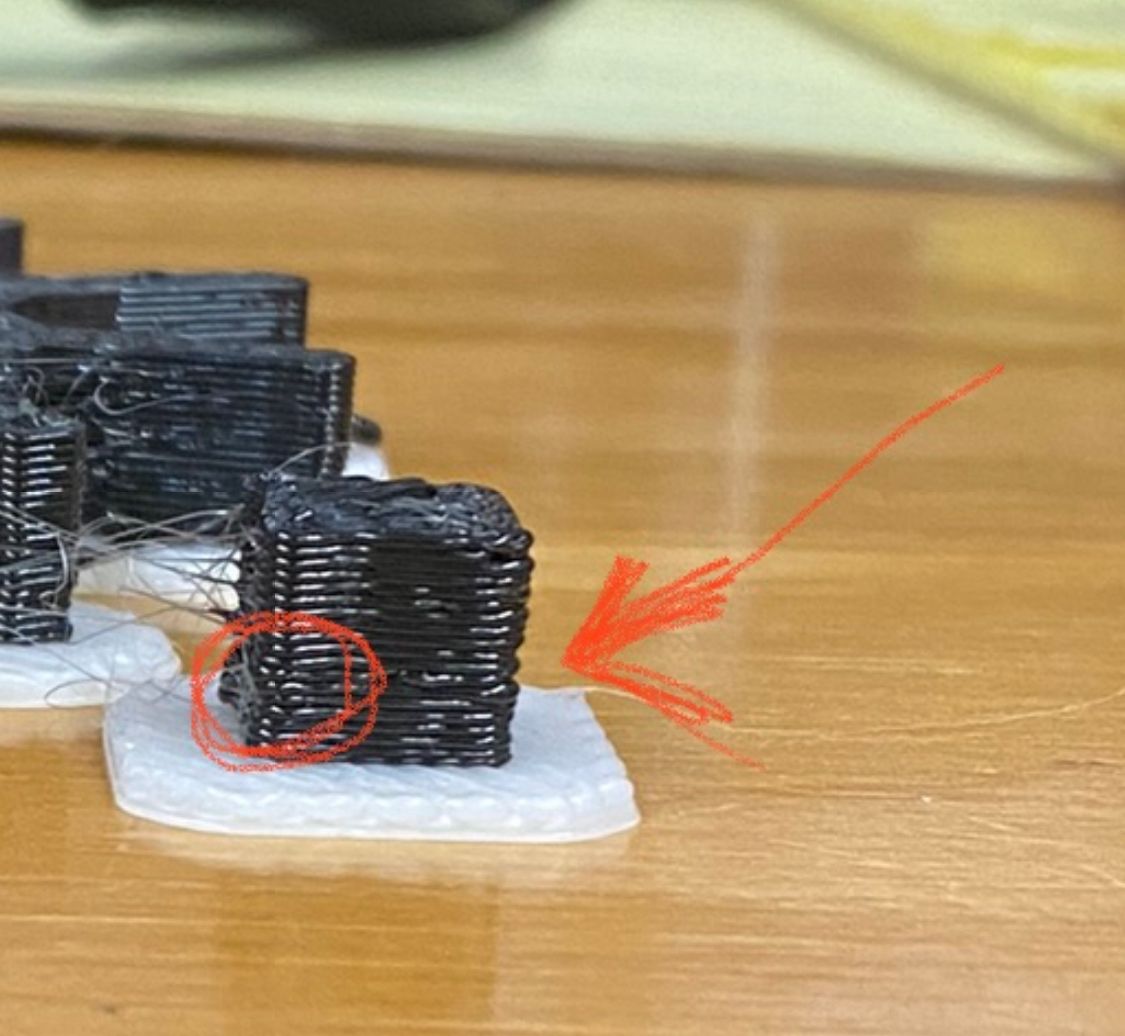

for the time being consider the images below of the part that will be featured in the video.

along with this synopsis:

The brim, raft and first 3 layers print on desirably (this has been typical.) Once the bottom solid layers finish the layers begin to shift little by little (in the magnitude of a fraction of a mm per layer).

I pause the print, home the toolhead, and resume the print and the next layer is nearly a cm off course.

I pause the print, home all, send some gcode that set the accelerations to 400 from 600, and jerk settings from 16 to 6. resume the print and we are back on target. I let the print finish using those low parameters and it seems to be okay.

Where the part has stringing and filament webbing out is when the accelerations and/or jerk caused the machine to not know where that tool head is located. I conclude that because when i update jerk and acceleration the and reset the toolhead it printed desirably.

Where i have circled showed the gradual start of the layer shifting. -

I wasn't able to find any info on the Aon M1, just the M2. But from what I saw it looks like a big machine. I would be surprised if the motors used such a low current but I guess if the expected speeds were very low maybe that is the case.

Does the mechanism itself move smoothly by hand (if that's even possible)

It's hard to see a layer shift with such rotund layers, but if you say so.

-

@Phaedrux Consider these examples. I have a box full of dozens of similar layer shifting for different part files too. In the example above I recognized it begin the slow shifting process and stopped it once I was convinced enough. I understand it is difficult to see but it was beginning to shift.

-

@Phaedrux said in Jerk Control M566:

I wasn't able to find any info on the Aon M1, just the M2. But from what I saw it looks like a big machine. I would be surprised if the motors used such a low current but I guess if the expected speeds were very low maybe that is the case.

Does the mechanism itself move smoothly by hand (if that's even possible)

if the motors are disabled they move pretty freely. If they are idle you can budge them provided you give a little extra force to do so. I imagine since the extruder motors are 1.3mA that the other ones driving the lead screws and belts are even higher rated that the extruders. I have a suspicion that my current ratings are low. I still have that in the back of my mind. Hopefully Aon will return my call or email back with some info regarding their legacy M1 model.