Giant Delta printer Slow Homing issue.

-

@sozkan By the way my Home Gcode

homedelta.g :

; homedelta.g ; called to home all towers on a delta printer ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Sun Sep 27 2020 20:52:39 GMT+0200 (Central European Summer Time) G91 ; relative positioning ;*** Slow homing has been configured. Change F90 to F900 below when your configuration is working G1 H1 X1805 Y1805 Z1805 F800 ; move all towers to the high end stopping at the endstops (first pass) G1 H2 X-10 Y-10 Z-10 F800 ; go down a few mm ;*** Slow homing has been configured. Change F90 to F360 below when your configuration is working G1 H1 X10 Y10 Z10 F800 ; move all towers up once more (second pass) G1 Z-15 F1200 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning G1 X0 Y0 F1000 ; move X+Y to the centre -

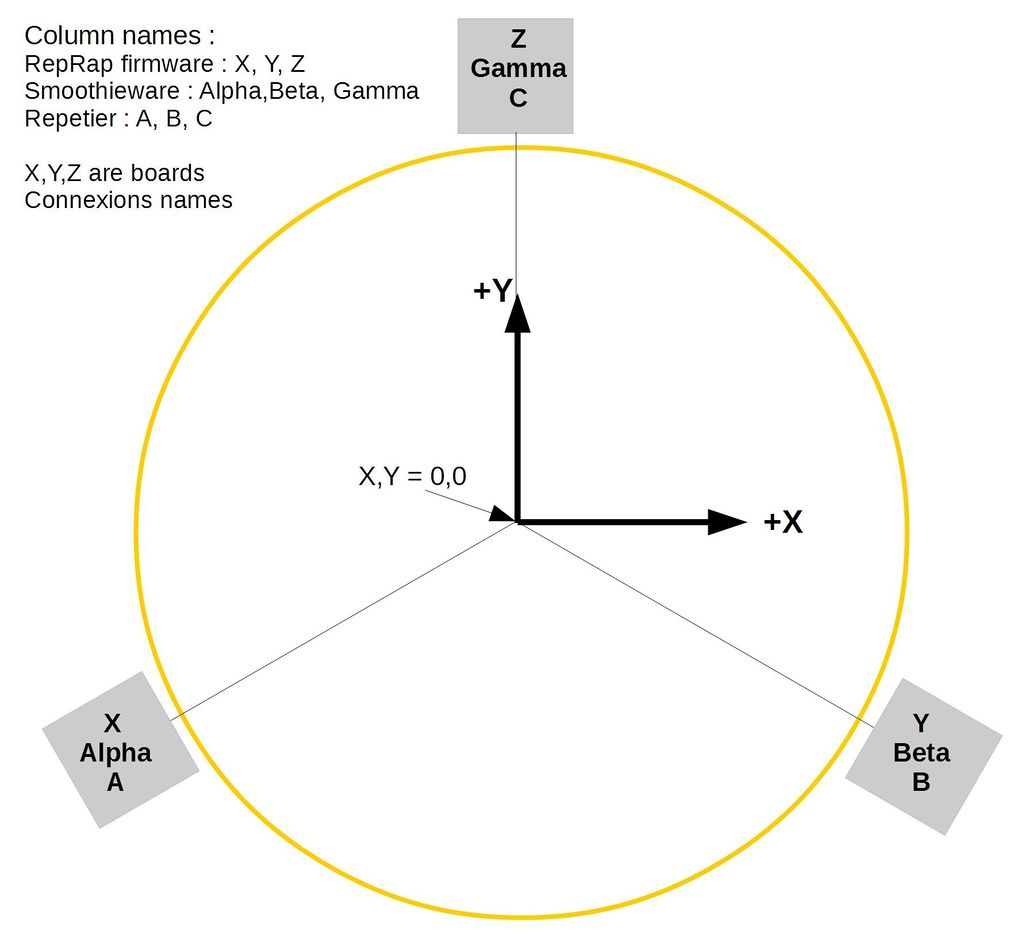

Are you sure the endstop for each tower actually corresponds to that tower at the board connection and firmware definition?

https://reprap.org/wiki/Delta_geometry#Delta_columns_and_axis_names

-

@Phaedrux said in Giant Delta printer Slow Homing issue.:

Are you sure the endstop for each tower actually corresponds to that tower at the board connection and firmware definition?

https://reprap.org/wiki/Delta_geometry#Delta_columns_and_axis_names

Yes exactly like this. Then, according to the documentation my setup correct, with no problems with the axis.

On every home, until the first and second end stops smooth move, then, the last one left noisy and slow down.

-

@sozkan this is the same issue you had when you didn't use P5, 6, 7 and 8 as instructed.

As you've indicated you've gone back to using the wrong numbers, of course your homing won't work correctly.

Us the correct motor P numbers otherwise we're never going to be able to help you -

@jay_s_uk said in Giant Delta printer Slow Homing issue.:

@sozkan this is the same issue you had when you didn't use P5, 6, 7 and 8 as instructed.

As you've indicated you've gone back to using the wrong numbers, of course your homing won't work correctly.

Us the correct motor P numbers otherwise we're never going to be able to help youThanks for your concern, but if you have seen above the P5, 6, 7 and 8 I have tried several times. It is in my mind always. The correct numbers P5, 6, 7 and 8. But I tried today as well. I did not work!

After setting up this recommend number, horrible sound even after the home. and moves are not calibrated. I don`t know why G91 moves even did not work correctly. I can make a video tomorrow about what exactly the difference.The present setting is are accidentally working fine but after home smoothly. I am not fun of numbers. If the recommended numbers works, Why I wouldn't?

-

Please post the exact M569 command you used with P5, P6, P7 and P8.

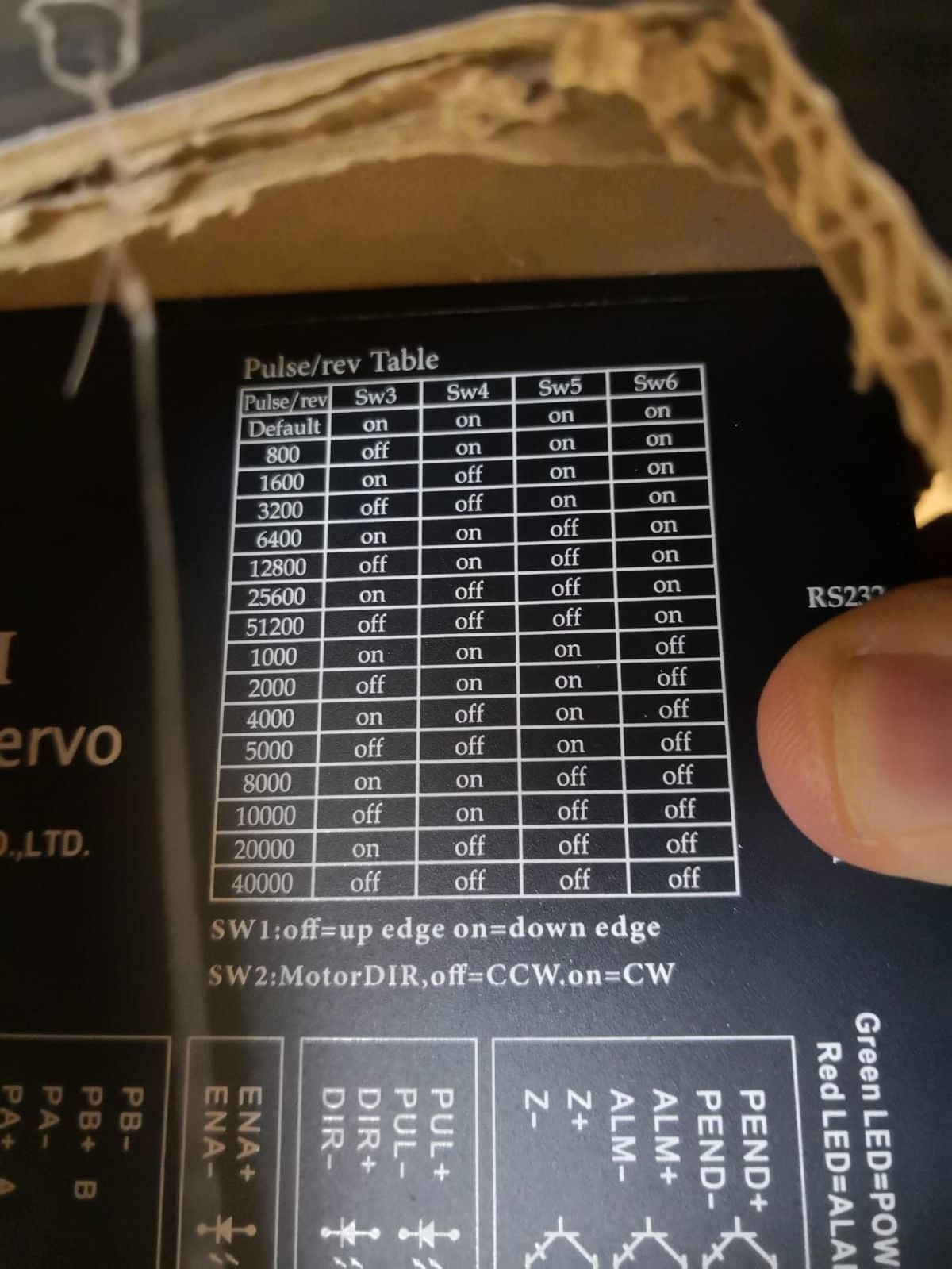

The "horrible noise" you mentioned might be caused by the motors recognising the commands but trying to move too fast, because of an error in the steps/mm setting, or the microstepping setting you are using on the external driver.

What switch settings are you using on those drivers?

Have you tested the motors individually as described at https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareDeltaPrinter#Section_Testing_the_motors_and_endstops_individually ?

-

@dc42

These are the present settings working smoothly after home.; Drives M569 P5 S0 R0 T3:3:5:0 ; Extruder drive 0 goes Forward M569 P2 S1 R0 T2.5:2.5:6:6 ; X:A drive 1 goes Forward M569 P3 S1 R0 T2.5:2.5:6:6 ; Y:B drive 2 goes Forward M569 P4 S1 R0 T2.5:2.5:6:6 ; Z:C physical drive 3 goes Forward M584 X6 Y7 Z8 E5 ; set drive mapping M350 X0 Y0 Z0 E0 I0 ; configure microstepping without interpolation M92 X114.29 Y114.29 Z114.29 E274.00 ; set steps per mm (400/140) * 40 = 114.2857 ;; 400 step per rev ;; 140 mm one rev pulley ;;1:40 ratio gearboxI have tested individual axis as well both with these settings and another (Correct) one as well.

However, I will do another youtube video to show you how it behaves.Steps / mm value is no different than earlier. Because I have added a locked 1:40 gearbox to keep axis from freefall.

Switch settings on driver 400 pulse/revolution.

-

@sozkan

Hello,

I have made a video on youtube to compare drive mapping the working accidental settings and recommended settings P values.

https://www.youtube.com/watch?v=tJFbPPyj9F0By the way, I keep the Extruder value( P5) as recommended. However, the extruder doesn't sound like cracking, but not calibrated moves in both settings. Since I don't know if the manufacturer (Dyze) gives the right settings, I don`t worry about the extruder now.

-

Here the individual axis trial video on Youtube,

https://www.youtube.com/watch?v=5fNw1B7A73g

Accidental or Illegal parameters on P values trial:

; Drives M569 P5 S0 R0 T3:3:5:0; Extruder drive 0 goes Forward M569 P1 S1 R0 T2.5:2.5:6:6; X: A drive 1 goes Forward M569 P2 S1 R0 T2.5:2.5:6:6; Y: B drive 2 goes Forward M569 P3 S1 R0 T2.5:2.5:6:6; Z: C physical drive 3 goes Forward M584 X6 Y7 Z8 E5 M350 X0 Y0 Z0 E0 I0; configure microstepping without interpolationAs Summary:

These setting working smooth, but before home, G1 command working smoothly on all axis like;G91 ; relative positioning G1 H2 X-100 Y-100 Z-100 F1000; go down a few mmBut when individual command sent, It does not work correctly, like these command;

G91; relative positioning G1 H2 X-100 F1000; go down a few mmRecommended Parameters on P values trial :

; Drives M569 P5 S0 R0 T3:3:5:0 ; Extruder drive 0 goes Forward M569 P6 S1 R0 T2.5:2.5:6:6 ; X:A drive 1 goes Forward M569 P7 S1 R0 T2.5:2.5:6:6 ; Y:B drive 2 goes Forward M569 P8 S1 R0 T2.5:2.5:6:6 ; Z:C physical drive 3 goes Forward M584 X6 Y7 Z8 E5 M350 X0 Y0 Z0 E0 I0; configure microstepping without interpolationAll the move commands work the same with the only problem, the horrible sound(sign for incorrect steps), and incorrect calibration distance. It is basically running a shorter distance than the previous parameter.

-

can you also post a picture of the switch settings on the drivers please

-

and using 0 in M350 is invalid.

A value of at least 1 should be used for all axis. e.g.M350 X1 Y1 Z1 E1 I0https://duet3d.dozuki.com/Wiki/Gcode#Section_M350_Set_microstepping_mode

-

@jay_s_uk said in Giant Delta printer Slow Homing issue.:

can you also post a picture of the switch settings on the drivers please

Default means 400 steps/Rev

-

@jay_s_uk said in Giant Delta printer Slow Homing issue.:

M350 X1 Y1 Z1 E1 I0

It did not make difference. incorrect steps remain in this mode. -

you've got the drivers set to 400 steps per mm, and i believe originally, you were looking at using 3200 steps per mm.

have you tried switching back to that?

That should reduce the amount of noise you are hearing -

@jay_s_uk said in Giant Delta printer Slow Homing issue.:

you've got the drivers set to 400 steps per mm, and i believe originally, you were looking at using 3200 steps per mm.

have you tried switching back to that?

That should reduce the amount of noise you are hearingIt was actually the previous setup. The sound and problem with the same setting remained at 3200 settings.

The reason 400 setting is on, I have added a 1:40 Gearbox. Therefore, 400 was an appropriate setting.

The new setup;

M92 X114.29 Y114.29 Z114.29 E274.00 ; set steps per mm (400/140) * 40 = 114.2857 ; 400 step per rev ;; 140 mm one rev pulley ;1:40 ratio gearboxHowever, It could be higher steps/mm with smoother settings variation, I would try. But Due to the high gearbox, it needs high-speed rotation to need on the motor. So, the lower step is lesser the signal density.

But the actual issue is not noise. Hearing noise is just a sign.

The actual issue is within the recommended P values noise into the signal output of the breakout board. I can connect an oscilloscope to prove it. Some missing steps cause less travel than the actual distance. -

The Motor Control Problem resolved! ( interns of calibration and successful machine move ) ( But I still need your valuable help on bed calibration Should I open a new thread?)

Thank you very much for all your contribution.

Solution: I have just upgraded to the latest beta Firmware and DWC.

Conclusion:

But the configuration remains as (P 2-3-4) I was using. The recommended P 5-6-7-8 values causing problems. If it is not an issue with "Duet 2 Wifi r.104" It is something with the firmware I believe.The Problem with recommended configuration P-values causing missing steps and noisy move. Each axis even the same amount moves command, they move different distances.

By the accidentally found settings and new Firmware update problem is over!

So this is the code that is working so far:

; Drives M569 P5 S0 R0 T3:3:5:0; Extruder drive 0 goes Forward M569 P2 S1 R0 T2.5:2.5:6:6; X: A drive 1 goes Forward M569 P3 S1 R0 T2.5:2.5:6:6; Y: B drive 2 goes Forward M569 P4 S1 R0 T2.5:2.5:6:6; Z: C physical drive 3 goes Forward M584 X6 Y7 Z8 E5; set drive mapping M350 X1 Y1 Z1 E1 I1; configure microstepping without interpolation M92 X114.29 Y114.29 Z114.29 E274.00 ; set steps per mm (400/140) * 40 = 114.2857 ;; 400 step per rev ;; 140 mm one rev pulley ;;1:40 ratio gearbox -

undefined sozkan referenced this topic

undefined sozkan referenced this topic

-

undefined sozkan referenced this topic

undefined sozkan referenced this topic