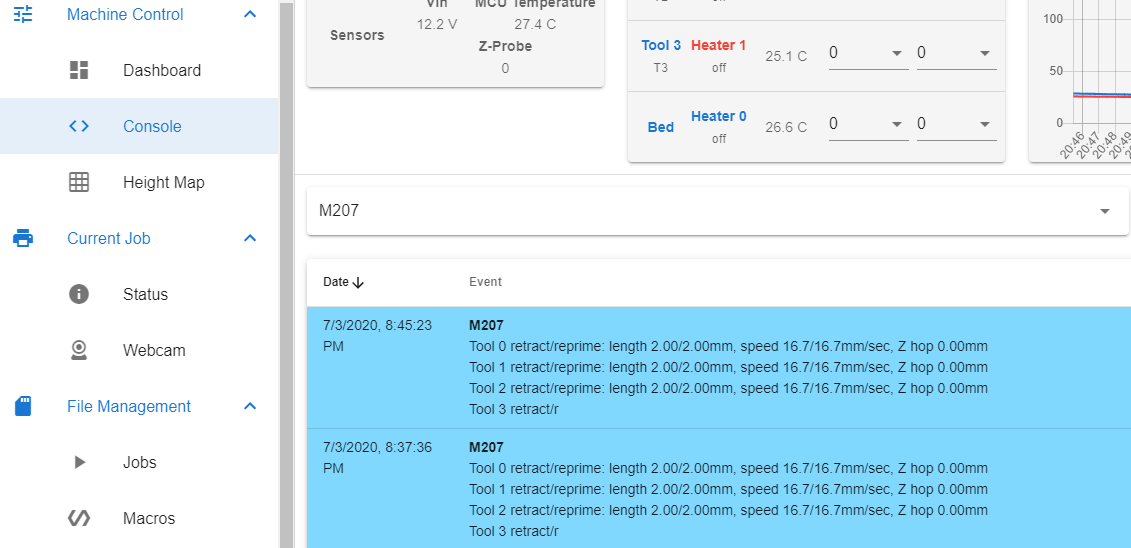

M207 response too long see console

-

So if you switch to the Console tab of DWC, what is the message?

-

Yes this is from the console.

-

Out of interest I get the same Response too long see console notification warning if I send M122. Not sure if that helps at all.

-

What is your DWC and firmware version?

-

@Phaedrux unless I’m mistaken the above photo shows my console screen where you can see the incomplete result of my M207.

What I can’t screen cap is the warning -

Sorry that should read I cannot screen cap the message because it times out

-

@lyndon any response longer than three lines generates the warning to see the console, as the message can’t be shown in a pop up. Not sure why you’re getting a truncated response though.

Ian

-

@lyndon Welcome to the insane world of mixing hot ends. I've never used Z hop so may not be much help. But post your entire config.g, I might be able to spot something. Also, let us know what version of firmware you are using.

As others have said, the "Response too long" message isn't an error. It just means that the response is too long to fit into a pop-up window so you have to look at the console to read the full response. -

@Phaedrux

Duet Web Control 3.1.0

Board: Duet 2 Maestro (2Maestro)

Firmware: RepRapFirmware for Duet 2 Maestro 3.1.0 (2020-05-15b1)

@deckingman

Yes it look like a fun world.Ref the response too long, I agree BUT that is my console screen. Not the M207 response in the pop up ??

as requested my config.g:-

; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M584 X0 Y1 Z2 E3:4:5 ; set drive mapping M350 E16:16:16 I0 M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M92 X80.70 Y80.70 Z400.00 E421.00:421.00:421.00 ; set steps per mm M566 X500.00 Y500.00 Z24.00 E250.00:250.00:250.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E3600.00:3600.00:3600.00 ; set maximum speeds (mm/min) M201 X750.00 Y750.00 Z120.00 E10000.00:10000.00:10000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-10 Y-20 Z0 S1 ; set axis minima M208 X310 Y310 Z380 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin !xstop M574 Y1 S1 P"!ystop" ; configure active-low endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds M950 S0 C"^zprobe.mod" ; create servo pin 0 for BLTouch G31 P500 X-20 Y-5 Z2.53 ; set Z probe trigger value, offset and trigger height M557 X30:310 Y10:300 S50 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off ; Old Tools ;M563 P0 D0 H1 F0 ; define tool 0 ;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets ;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;M563 P1 D1 H1 F0 ; define tool 1 ;G10 P1 X0 Y0 Z0 ; set tool 0 axis offsets ;G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;M563 P2 D2 H1 F0 ; define tool 2 ;G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets ;G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ;New mixing tools ; Retraction M207 S7.5 R0.0 Z0.2 F2400 ; Testing Preasure advance ;M572 D0 S2.0 ; set K-factor ;M572 D1 S2.0 ; set K-factor ;M572 D2 S2.0 ; set K-factor M563 P0 D0:1:2 H1 F2 ; Define tool 0 G10 P0 X0 Y0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C M568 P0 S1 ; Enable mixing for tool 0 M567 P0 E0.96:0.02:0.02 ; Set mixing ratios for tool 0 (90%,5%,5%) M563 P1 D0:1:2 H1 F2 ; Define tool 1 G10 P1 X0 Y0 ; Set tool 1 axis offsets G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C M568 P1 S1 ; Enable mixing for tool 1 M567 P1 E0.02:0.96:0.02 ; Set mixing ratios for tool 1 (5%,90%,5%) M563 P2 D0:1:2 H1 F2 ; Define tool 2 G10 P2 X0 Y0 ; Set tool 2 axis offsets G10 P2 R0 S0 ; Set initial tool 2 active and standby temperatures to 0C M568 P2 S1 ; Enable mixing for tool 2 M567 P2 E0.02:0.02:0.96 ; Set mixing ratios for tool 2 (5%,5%,90%) M563 P3 D0:1:2 H1 F2 ; Define tool 3 G10 P3 X0 Y0 ; Set tool 3 axis offsets G10 P3 R0 S0 ; Set initial tool 3 active and standby temperatures to 0C M568 P3 S1 ; Enable mixing for tool 3 M567 P3 E0.34:0.33:0.33 ; Set mixing ratios for tool 3 (34%,33%,33%) M501 ; use head pid overrideMany thanks Lyndon

-

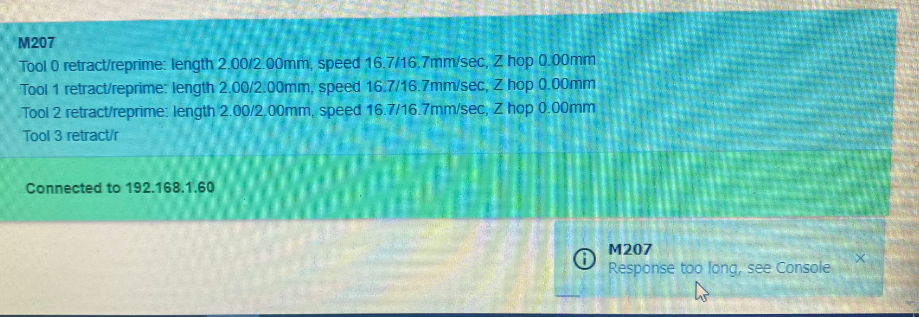

Here is a photo of my console screen with warning. Please excuse the quality

-

@lyndon Those look like default values to me because not only is the Z hop at zero, but also the retract length is being reported as 2.00 whereas according to your config.g, it should be 7.5 mm.

Possible reasons are that there might be another M207 somewhere which is overriding the first one. Try sending M98 P"config.g", to re-load then send M207 again.

Alternatively, you might need to update the firmware. The latest version for my gen 3 boards is 3.1.1 but I' not sure if that applies to the Maestro as well. -

Quick follow up after some more play time, I have found the M207 retraction code line must come after tool definitions in config.g. Now I have accurate values in the console response to M207. However still truncated and I do still get the pop up message response too long.

;New mixing tools M563 P0 D0:1:2 H1 F2 ; Define tool 0 G10 P0 X0 Y0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C M568 P0 S1 ; Enable mixing for tool 0 M567 P0 E0.96:0.02:0.02 ; Set mixing ratios for tool 0 (90%,5%,5%) M563 P1 D0:1:2 H1 F2 ; Define tool 1 G10 P1 X0 Y0 ; Set tool 1 axis offsets G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C M568 P1 S1 ; Enable mixing for tool 1 M567 P1 E0.02:0.96:0.02 ; Set mixing ratios for tool 1 (5%,90%,5%) M563 P2 D0:1:2 H1 F2 ; Define tool 2 G10 P2 X0 Y0 ; Set tool 2 axis offsets G10 P2 R0 S0 ; Set initial tool 2 active and standby temperatures to 0C M568 P2 S1 ; Enable mixing for tool 2 M567 P2 E0.02:0.02:0.96 ; Set mixing ratios for tool 2 (5%,5%,90%) M563 P3 D0:1:2 H1 F2 ; Define tool 3 G10 P3 X0 Y0 ; Set tool 3 axis offsets G10 P3 R0 S0 ; Set initial tool 3 active and standby temperatures to 0C M568 P3 S1 ; Enable mixing for tool 3 M567 P3 E0.34:0.33:0.33 ; Set mixing ratios for tool 3 (34%,33%,33%) ; Retraction M207 S2.5 R0.0 Z0.2 F2400That said I seem to have a printer that's now listening to my retraction settings.

But before moving the M207 line in config.g, the machine was retracting I guess by the values shown in my previous M207 response. Perhaps this is a default setting.

So when I was dynamically changing retraction during a print by sending console M207 bla bla bla, I may not have been changing anything hence no improvements to print quality.

More fun to be had

-

@lyndon You will always get that pop up message. It isn't an error or warning. It is merely to draw your attention to the fact that the response was too long to fit in a pop-up window and that you should look at the console to see the full response.

Yes, as stated above - those values look like default values.

BTW, I just tried sending M207 on my machine and I too get the same truncated response. Although, because M207 gets applied to all tools, one could argue that the response is unnecessarily long, as it only needs to report one set of values. This seems to be a minor issue with DWC which ought to be brought to the attention of ChrisHam. But I wouldn't worry about it - it won't affect anything.

-

@deckingman said in M207 response too long see console:

M98 P"config.g"

Console response to the above is again truncated and is:-

M98 P"config.g" HTTP is enabled on port 80 FTP is disabled TELNET is enabled on port 23 Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C The M568 command is no longer needed The M568 command is no longer needed The M568 command is no longer needed The M568 command is no longer neededFollowed by the same pop up. Response too long.

I agree and understand and the message doesn't bother me as much as the truncated responses, I'm getting it on several M codes such as M122

PS I have also updated dwc and firmware to ver 3.1.1

Cheers -

@lyndon That response is fine. It isn't truncated. That is the normal response from running the macro "config.g".

BTW, as you can see, you ought to remove all those M568 commands from your config.g. Since firmware 1.19, setting the mixing ration with M567 automatically turns on mixing.

I have started a new thread in the DWC section to bring the M207 response to Chris Ham's attention.

-

@deckingman oops my bad it looked truncated.

I have now removed the M568 from config as suggested.

Cheers all

-

I've made a note to fix the truncation of M207 output when there are >= 4 tools in firmware 3.2.