NEJE-like Laser as CNC upgrade

-

I was referring to this thread

https://forum.duet3d.com/topic/15826/behavior-of-m3-command-im-laser-mode-m452

where @dc42 said there was a request to have a laser mode available for focus. Was just wondering if it ever went anywhere.

Oh well, at least I have it working now. That was the major hurdle. -

Hello and sorry for editing this topic but I'd like to ask to @FelixH or @sh12 or some kind friends here to help me with the same setup (workbee, duet2 wifi, neje 20w). I can't get rid of it knowing how to wire and how to change the right settings/macros or flashing to RRF3 or making the special inverter board.

Maybe on my personnal mail box or a new topic ?

what's the best way ?

Sorry but i come from Grbl world

-

@g0rg to be honest, I have been incredible busy the last few months to even considering doing the upgrade... last thing I did was to design a small PCB to connect the laser. It is more or less the same as described in the Duet Wiki, but for through hole components. I shall be able to get into it in a couple of weeks. My setup is still the same: Workbee with Duet, running the latest Ooznest version of the firmware. I guess it is a standard RRF2, but I don‘t know. I am guessing the folks at Ooznest only changed the Web Interface to make it more CNC-friendly, which makes me think if I should update to RRF3 or not.

-

@FelixH from what I gather Oozenest is working on a RRF3 update.

-

@Phaedrux cool! I‘m looking forward to it. With some luck they will incorporate the autosquare feature, if I’m not mistaken it should be easier with RRF3

-

@bearer said in NEJE-like Laser as CNC upgrade:

a little OT, but M997 ignores M505 or is it just me?

Yes, M997 always looks in /sys, and uploads of .bin and .uf2 files always go into /sys.

-

@FelixH I already setup my workbee with autosquare on homing by adding a second switch on Y axis.

As a test purpose i updated a second duet wifi board with RRF3 and i still try to understand how to wire my laser and still try to understand how to spell the fan port i would like to use

maybe a help from @sh12

maybe a help from @sh12

-

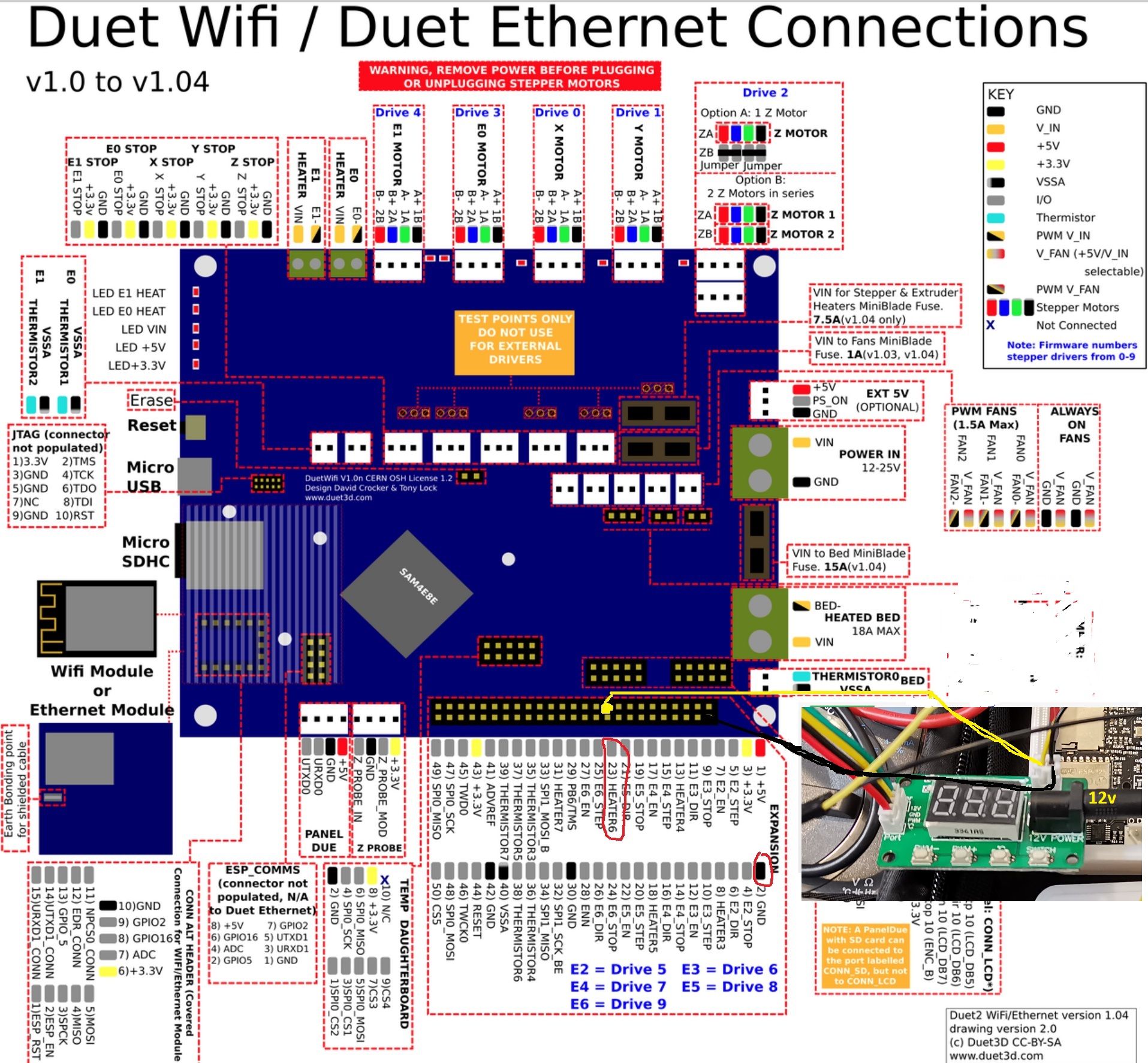

The recommended way to drive an active-high laser PWM input is to use a 74HCT02 to invert one of the PWM signals on the expansion connector and gate it with +3.3V. However, if your Duet 2 is out of warranty, you could tap into one of the heater mosfet gate pins instead, if you are not using all three heater outputs.

-

Hi all again,

I am today trying to wire the laser but, before I do I have a doubt regarding the following diagram:

https://duet3d.dozuki.com/Wiki/Laser_PWM_control

in this diagram, what is exactly HEATER_3 ?? It is the heated bed, extruder 1 or extruder 2 ?? Also, I am assuming is the "negative" pin of said heater, right?

-

I installed a similar NEJE laser ("30W" with ~7.5W optical) and got it working easier than expected after reading all the forum posts. Maybe having the Duex5 was key as it just plugs into +/- of servo plug. The TTL Board that comes with unit has 3 modes when you push the pwr button: Off, Manual PWM via board buttons, and PWM-input-controlled.

I have been using Lightburn for Marlin with "inline" selected for "Laser Control Commands" to make gcode.

;Laser T6 Tool Definition

M307 H6 A-1 C-1 D-1; disable heater6 channel

M563 P6 D0 X3 ; Tool 6 Laser on U axis no heater or fan (change if on X axis)Tpre setup:

M452 P6 R255 F10000 S1 I0 ; switch to laser mode Heater 6 PWM/servo to control the laser

M42 P6 S0 ; Ensure Laser Off

TFree setup:

M451; Go back to FFF 3D print Mode -

@PopstarPorcupine thanks a lot for your info. I prepared the mentioned board and I used the heated-bed PWM port. I still have to bring it on-line, however. Not tried it yet. I've been really busy preparing a new electronics box for my Workbee with the Duet, the SuperPID and everything else... I think your snippets will be much uselfull. Thanks a lot again.

EDIT: what about the Lightburn software? is it worth it? There are not many options for for mac users, Lightburn beign one of the few I found...

-

Well just an update on my side. I finally finished upgrading my Workbee with a worthy electronics box where everything is well organized. I never liked it to have the controller board exposed and on the moving gantry.

Anyway, I've been able to put my laser to work by following the indications here. I used the brake-out board suggested and it works just fine. Amazingly enough, it worked on the first try, which for my standards is amazing to say the least.

I have a problem though when switching back to CNC mode and it is the following error:

M98 P"0:/macros/Laser/Switch to CNC" CNC mode selected Error: G10: Attempt to set/report offsets and temperatures for non-existent tool: 999The macro I'm using to switch back to CNC mode is the following, which is a mix between what I've seen and what I found on my config.g file

M106 P2 S0 ; turn off 12v PSU M453 ; Put the machine into CNC Modes M140 H-1 ; Disable heated bed M564 S1 H1 ; Disable jog commands when not homed M911 S21.0 R23 P"G91 G1 Z3 F1000" ; Configure power loss resume M501 ; Load Stored Parameters M98 Pcustomconfig.g ; Execute custom config settingsany clue in what is this about? it would be much appreciated!

-

@FelixH said in NEJE-like Laser as CNC upgrade:

M501 ; Load Stored Parameters M98 Pcustomconfig.g ; Execute custom config settings

What do you have in config-override.g and customconfig.g?

-

@Phaedrux thanks a lot for your help. Actually shortly after I posted the question I found where the problem was. The command disabling the heated bed was being called twice. I cleaned it up and now everything seems to be working just fine. Thanks a lot again!

-

Hi.

I have successfully installed a NEJE 30W laser on my MPCNC powered by Duet 2 Wifi, FW version 3.2.2.

I have not used any additional boards or circuits other than the supplied test board.

The test board is ideal as you can put the laser in test mode with power 001 to focus it and than switch to TTL mode to run the job.

This is the pins that I have used:

In the configuration i have added this lines and commented out the one with M453:;M950 H6 C"nil" M452 C"exp.heater6" R255 S1 F20000I hope that helps someone as i had to read hundreds of forum pages to get this far...

-

@mdalacu Are there not any downsides with connecting this way? The laser wiki states you need a specific electronics to attach a laser to the Duet2. I'm thinking you may fry your Duet if 12v from your test board runs back into it.

-

@chimaeragh I really hope not. The test board underneath the display has an integrated circuit. I think it basically does the same thing as the circuit on the wiki. But I am not an electonist...by any means.

What can I tell you is that after almost 1h of total burning time, everything still works perfectly!

-

@mdalacu I hope so. From the wiki... [Laser PWM Control( https://duet3d.dozuki.com/Wiki/Laser_PWM_control)

The circuit diagram for the needed circuit, including protection for shorting of 3v3 line to prevent unintended Laser Power on is shown below.

I do not think the test board has a 74HCT02 Quad NOR Gate.

-

@mdalacu I don't think they designed the circuit @chimaeragh displays just for the sake of it. I actually build that circuit with TTH components and it has been working great

-

@chimaeragh @FelixH Maybe someone with more knowledge than us could look at that test board and tell us if it is safe.

The test board has an IC roughly the same size as 74HCT02 underneath the 3 digit display, but I can not tell which one. I don't what to disassemble the board since it is working just great.