Independent Z Leveling

-

@dc42 I was wondering about that. The bed is a Mic6 plate so it should be flat to about .15mm but I guess thats the deviation its measuring. I'm trying to understand how you can determine the flatness of the plate from only probing three points.

I think its probably that all three of the rails are not in parallel to each other. Most notably the back center rail. I may need to work on aligning it better with the other two. -

@3DPrintingWorld said in Independent Z Leveling:

I'm trying to understand how you can determine the flatness of the plate from only probing three points.

You can't. I am assuming that you homed Z by doing a single G30 probe near the centre of the bed. That gives a 4th point.

-

@dc42 You are correct. I seem to be saying that with every reply.

It does probe in the center first. I was wondering if that probe was needed and if it is taken into account because its not in "BED" file.

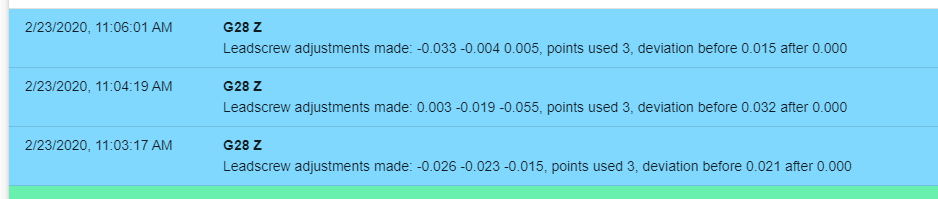

It does probe in the center first. I was wondering if that probe was needed and if it is taken into account because its not in "BED" file.This looks better! I have two flex plates, I was originally testing on a buildtak and had a thought that there might be bubbles that I cant see bc its black. I switched to my clear PEX sheet and got much better results!

Now that I know the bed is flat is there a reason to keep the first probe in the center?

-

You don't need to probe in the centre before you do the three G30 probes near the leadscrews, assuming you have homed Z at least once since power up. However, I recommend that you probe the centre (e.g. by doing G28 Z) at the end, in case there is a difference in height between the middle and the edges.

-

I'm not an engineer but

I became interested in assembling a 3D printer and there were questions on which I have not yet decided. Can I ask you in this forum what is wrong I am writing in the config.g so that the Z sensor starts working -

@Vladimir said in Independent Z Leveling:

I'm not an engineer but

I became interested in assembling a 3D printer and there were questions on which I have not yet decided. Can I ask you in this forum what is wrong I am writing in the config.g so that the Z sensor starts workingYes of course; but please start a new thread for your post, describe the problem you are having, and include your config.g file with your post.

-

Now I made the record right? is it new thread for my post

-

Good afternoon

Please help with the Сonfig file for Duet Wi Fi version 2.03

I assembled a Cartesian printer where XY moves in the same plane with ball screws and 3 step motors

the Z table is lowered with balls crews and 2 step motors. I connect inductive sensor NPN normally open;( works at a height of about 2 mm from the Al table in my opinion the sensor response level is low to a heated table)

The problem is that I can’t level Z table with a probe and I can’t get a table map and auto-calibrationPlease help me what am I doing wrong

kind regards

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.6 on Tue Jan 14 2020 10:57:13 GMT+0300 (Москва, стандартное время)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Gnutik" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

;***************************************

; M564 S0 H0

;***************************************

; Drives

M569 P3 S1 ; physical drive 3 goes forwards Extruder

M569 P0 S0 ; physical drive 0 goes forwards drive Y

M569 P1 S0 ; physical drive 1 goes forwards drive Y

M569 P2 S0 ; physical drive 2 goes forwards drive X

M569 P5 S0 ; physical drive 5 goes forwards drive Z

M569 P6 S0 ; physical drive 6 goes forwards drive Z

M584 X2 Y0:1 Z5:6 E3

;***********************

M671 X-27:980 Y21:21

;***********************

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X400.00 Y400.00 Z1280.00 E418.50 ; set steps per mm

M566 X400.00 Y400.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min)

M201 X400.00 Y400.00 Z10.00 E250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X300 Y200 Z0 S1 ; set axis minima

M208 X750 Y450 Z500 S0 ; set axis maxima

; Endstops

M574 X0 S0 "X-stop"

M574 Y0 S0 "Y-stop"

M574 Z0 S0 "Z-stop"

; Z-Probe

M558 P5 I1 H5 F120 T6000

G31 X0 Y0 Z0,1

M557 X30:740 Y0:450 S20 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B0 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

M501

-

@Vladimir You're still posting inside someone elses topic. Create a new topic from the main forum. https://forum.duet3d.com/category/5/duet-hardware-and-wiring

-

@dc42 If I issue a G28 Z then wont it start to start a cyclic dependency. Since homez has a G32? Or should the G32 only be in home all?