BondTech BMG Extruder for Delta Recommendation?

-

-

I second jay's flying extruder approach.

If you're using a smart effector, you can use the 3 extra holes to affix the extruder mount to the effector, so that the bowden tube isn't the only thing connecting them.

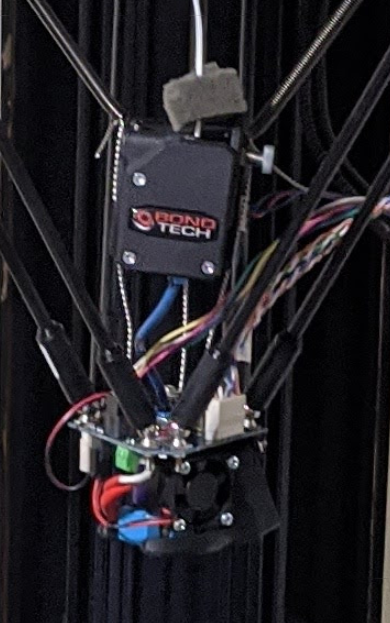

Not the greatest picture, but you can see the 3 sets of twisted pair 24(i think) gauge aviation safety wire going up to the extruder. I anchored them to 3 M3 bolts going into the 3 otherwise-unused holes in the smart effector. Then they just wrap around the springs at the extruder mount. My bowden tube is actually 'too long' for this but that means there is just more force keeping it held in place between the hotend and extruder.

Bondtech extruders are great. You'll never see stripped filament again.

instead, the bowden tube will strip itself out of the collets if you exceed the volumetric extrusion rate your hotend can do. I'd say this is kind of a con. stripped filament is easier to deal with than stripped bowden tube. But the bowden tube is more durable, so it would happen less often.I think the standard kit BMG comes with a little pancake stepper. Still a nema 17, but its much smaller than the one in jay's pic there. His is a clone, so maybe that's why.

-

@3mm said in BondTech BMG Extruder for Delta Recommendation?:

recommendations

bondtech is great extruder, but I'd think about flex3drive for delta, especially if you wanna print flexibles... much better solution IMO, especially the new G5 rocks.. it's light, fast, durable, printable and open source

.. Jason overdid himself with this one

.. Jason overdid himself with this one

-

I use a genuine BMG on my delta and I am very happy with it. I don't yet use a flying extruder.

-

@dc42 said in BondTech BMG Extruder for Delta Recommendation?:

I use a genuine BMG on my delta and I am very happy with it. I don't yet use a flying extruder.

Me also. I have a large-ish (two meter tall, 600mm Z printable) with about one meter of bowden, and an AKL+ with about 1/3 meter of bowden. Both with BMG mounted on a tower, about 2/3 of print height.

Both will print some flex materials; neither will print the really floppy stuff.

LOVE the BMG.

-

I have a BMG on my mini kossel with 500mm bowden and it can't print really flexible filament. Everything else prints very nicely, it's the best extruder I have tried. I also have a kossel xl that is fitted with a flex3drive and that prints flexibles OK.

-

@jay_s_uk, DrofTarts, oryhara, smece, DC42, Danal, burtoogle, et al,

Thank you for all the recommendations.

I purchased a BondTech BMG from FilaStruder last evening & a pancake (42STH25-1404) stepper with a metal bowden tube coupler-adapter.

@jay_s_uk, your turning your printer upside down, heh heh, that's cool! I did not think of that. I planted my DUET-E controller in a forced-air box on a tower about six inches above the base, however, that may be the source of a side centric print artifact I am seeing..

@oryhara, I presume that the chains are intended to constrain the flying platform from swinging about too much? And may I ask, what is ghosting?

Initially I'll mount the extruder on a tower and guide the filament using 511mm length of bowden PTFE tubing to the SmartEffector/E3D-V6 hotend, although, later I intend to implement a flying extruder platform. I desire to experiment with both deployment arrangements.

Thanks.

3mm

-

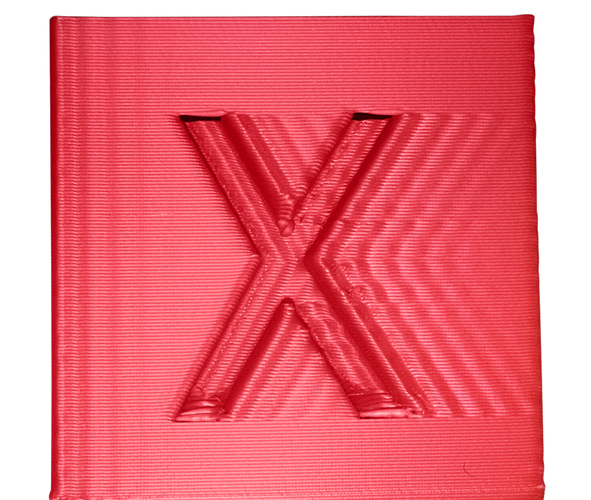

@3mm Ghosting is repetitive patterns on your print following a point where the hotend changes directions...things like a hole or notch in your print and you will see similar looking artifacts on your prints following it.

If you search 3d print ghosting on google, many pictures will come up showing this.

This is a perfect example of it.

-

Hi JamesM,

Thanks for the photo. Do you know what caused this artifact? Was the problem remedied?

3mm

-

@3mm affirmative.

And without them, the only thing connecting the effector to the extruder is the bowden tube. Which is subject to force in the same direction from the extruder pushing filament through it. The springs are pulling it in the same direction, adding to the force on the bowden tube. By having the wire connecting them, and the tube a bit too long, it is now only subject to the force of the filament going through it.This has another benefit(which i just noticed): The springs for the flying extruder don't reach their slack or near-slack position, so they maintain a more constant force on the extruder. They make less noise.