Repetitive layer defects

-

@denis said in Repetitive layer defects:

@doctrucker I would like to hear some reasonable thoughts, instead of an answer, that this is a problem of such printers. You can write shit happens, it will be just as useful

Your response makes little sense, and I've no time to waste freely with tone like that. I wish you luck fixing your problem. Good bye.

-

@edgars-batna Yes, and I see a change. Now I will try the leading pulleys made of polyurethane (Perhaps Chinese iron curves in places. suddenly help?)) and then publish a photo with reduced extrusion. Down to 85 percent. There is something to think about. In addition, in the spiral mode in one layer, the wall is ideal.

-

@edgars-batna It was a good idea. I see the problem in extrusion. Strange, because I calibrated it. It seemed to me that the calibration procedure should not be questioned. However, all I can say is that the problem exists, and I can only reduce the extrusion in order to get a quality print. This may be the uncoordinated steps of the engines of extruders and axial engines, but let the developers explore this. It is a pity that I changed the printer to the delta after buying a duet and lost several months of time)) I thought I was struggling with the wobble, but it turned out that it wasn’t.

-

@denis It is practically the same what I observe on my printer, even though it is a completely different build.

Though, what I meant is not the overall extrusion multiplier, but rather extrusion width in slicer settings. So, for 0.4 nozzle set it to 0.3 for perimeters.

The amount of material will still be as you calibrated it, but the perimeters will be significantly finer. It reduced most of the ripples for me.

-

@edgars-batna Now I use a 0.3 nozzle, but the general idea is clear to me. This is really strange, because these defects began after I changed the marlin to a duet for HBot and were aggravated during the transition to the delta. After the adjustment, I get excellent prints, so I don’t scold the duo in any way, but I urge the developers to check the algorithms again.

-

@denis Yes, I had exactly the same thoughts and couldn't figure it out either. One observation that I've made is that there have been threads with printers that use linear axes that encounter similar Z ripples, so one would think it's not mechanical, but wait...

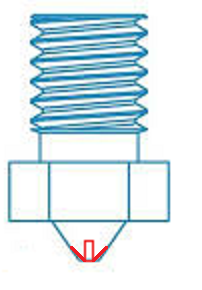

My current theory is that the E3D-type nozzles with a flat area around the nozzle hole is what's causing it. There's a snowball effect where the nozzle rides on top of the previously extruded perimeter, thus it is pushed upwards slightly. Just 25% of layer height and there you go - it will start snowballing and oscillating, since at high enough pressure the filament will get pushed down and then it starts over. Basically, as soon the nozzle can be pushed upwards by a fraction of layer height, the problem starts. We're already in fractions of a millmeter; these tolerances are hard to achieve at home.

Well, this is a theory. To prove it one would need to take a nozzle and sand it down like this:

But I haven't tried it yet. Sounds EZ... but, it might destroy lines where extrusion is larger than the nozzle...

-

@edgars-batna Well, I am glad that this situation can be influenced and we know how.

-

Unfortunately, the reduction in extrusion only masks the problem, but does not solve it. Lines are still visible. It seems to me on different sizes they appear with a different period. What else can you pay attention to? Any advice.

-

@denis Astounding, but indeed, you get the same behavior as on my completely different printer (Hevo CoreXY)... I suppose the common denominator is some aspect of the hotend. How much play can you observe on the nozzle when it's cold by hand? Just try it by hand; it should be reasonably stiff for pulling or pushing the filament, plus pressure inside the Bowden tube, if any.

My hands are itching to try my nozzle-destroying theory, but I don't want to disassemble the hotend yet again and I don't have a 0.4 Volcano nozzle to play with just yet.

Also, what slicer do you use? I use Slic3r PE.

So far I observed that cooling affects this. Less cooling means the top layer is soft enough to not lift the nozzle. Can you try printing same piece with significantly less cooling and significantly higher speed?

-

@edgars-batna This is ABS and it was printed without cooling. I can include about 10 percent, but this will not affect the review picture. Waiting for PT100 and fisheye for further experiments. I used Simplify3D and Сura, hotend fixed well

-

@denis Another aspect that I noticed is that Slic3r PE does not produce all layers in the same direction and that the segments may not line up. It alternates between clockwise and counter-clockwise and does not line up corners of approximated curved perimeters between layers, which means the hotend will lag differently behind the target position. Can you check if all layers are printed in the same direction, in case it also affects other slicers?

-

Have we already established that you are not using bang-bang control for the bed heater? Send M307 H0 to check. This is known to cause that type of problem. Note, if you haven't tuned the bed heater yet then it runs in bang-bang mode.

-

@denis said in Repetitive layer defects:

1_1551779528546_config.g 0_1551779528545_config-override.g

; config-override.g file generated in response to M500 at 2019-03-03 15:19

; This is a system-generated file - do not edit

; Delta parameters

M665 L397.107 R157.000 H523.288 B175.0 X0.000 Y0.000 Z0.000

M666 X0.653 Y-0.205 Z-0.447 A0.00 B0.00

; Heater model parameters

M307 H0 A162.7 C784.3 D2.7 S1.00 V23.9 B0

M307 H1 A1059.6 C247.6 D5.9 S1.00 V23.6 B0

It appears to have been tuned.

-

I'm using bang-bang below an 8mm Aluminum plate and the symptoms are nearly identical. Using PID with a 1200W 220V heater would probably melt something somewhere. The heat appears to take a good while until it propagates to the top anyway as it's a grade of aluminum with just average thermal conductivity. Plus, the symptoms are sure to appear without heat bed turned on.

-

@edgars-batna said in Repetitive layer defects:

Using PID with a 1200W 220V heater would probably melt something somewhere.

If controlled by SSR, what would melt?

-

@phaedrux Well, if you take any SSR with a spec sheet, you'll see it's rated for a limited amount of on-off switches per hour or something like that. At least that's what I could find at the time. If you have an SSR with a spec sheet with unlimited switching capability for this amount of power, kindly let me know. I've seen people complaining about their cheap Chinese relays melting "unexpectedly" at some point when they're not at home and it's no wonder. Some try to control the heating system at their homes.

-

-

@deckingman Wouldn't the high inrush current trigger the breakers? What about switching this 10 times a second?

What I've got now is this: https://docs-emea.rs-online.com/webdocs/16bc/0900766b816bcc73.pdf (the 77.11.8.230.8251 variant)

It's recommended to be switched around 2000 times an hour in the spec sheet. I can't find this sort of information in the other spec sheet anywhere. Am I just blind?

-

@dc42 The operation mode of the bed heater doesn't not affect my printouts. I printed on the cold bed and got the same results. (But will try again)

There is an idea to print the perimeter in the vase mode and also in one layer in the usual mode, as well as two perimeters near each other in one layer in the usual mode. I think if in normal mode I get lanes, it will be a positioning error. -

@edgars-batna said in Repetitive layer defects:

@edgars-batna said in Repetitive layer defects:

@deckingman Wouldn't the high inrush current trigger the breakers? What about switching this 10 times a second?

What I've got now is this: https://docs-emea.rs-online.com/webdocs/16bc/0900766b816bcc73.pdf (the 77.11.8.230.8251 variant)

It's recommended to be switched around 2000 times an hour in the spec sheet. I can't find this sort of information in the other spec sheet anywhere. Am I just blind?

Mine has been running for about 3 years with no problems. It's what they are designed to do. This isn't really my field of expertise but they usually work as zero crossing switches. That is, it only switches when the AC sign wave crosses between positive and negative so not when a high current is flowing (no doubt someone with more knowledge than I will correct me if I'm wrong or give a better answer).

An SSR is a Sold State Relay and inside it is triac or some such solid state device, so in operation, it's very much like a Mosfet that we use on hot end heaters - just capable of switching higher currents. IIRC, the PWM frequency that the firmware uses for bed heaters is 10Hz so very low.

Trust me, hundreds if not thousands of people use them to control their mains powered heaters.