Yet another cast aluminum plate topic...

-

Here's what a 750W Keenovo heater does on a 300x300x8mm MIC6 plate set to 100C:

Notice that the ears of the plate read much cooler than the rest of the plate. It looks like temperature drops off rapidly as you move away from the outline of the heater, so using an oversized plate may not provide any more printable area.

-

@mrehorstdmd it'll be interesting to see how it turns out for me. I've ordered a 120v 1000w 450×450mm Keenovo, due to the holiday in China I likely won't receive it until the end of February. I'm going to try adapting the mount design you used. Where did you get the Teflon blocks from?

-

@dc42 The conundrum is the nozzle and cradle assembly sit very low, so I can't clip to the rear of the plate at all as it juts out 3 inches from the bed, the build plate sits very close to the the tray- so much so that the clip interferes with the adjustment of the bed, I could install larger springs however.

I only print on build mats, these require a scraper and mild rapping on the handle, this moves the plate around.

Clipping onto the this thin bed causes the mirror to warp.

I would buy a CNC'd bed, but the one available requires an expensive silicone heating mat $140 I can't justify just yet.

Glass has a lot less expansion when heated and mirrors are usually very flat, I don't use a probe, so if the build plate is warped i'm SOL.

With A/C heating mats, is there not a way to use the duet signal to turn on/off control the heat? everything I have seen uses a dedicated controller.

-

I will never go back to a rolled plate for any size above 250. The cast aluminum does not warp as much as the rolled/extruded ones so they are necessary for any bigger area

Here is what I now have on the V-King CoreXY

Video -

@tletourneau said in Yet another cast aluminum plate topic...:

@dc42 OT but do you think this paint would work with the mini differential IR sensor?

Rust-Oleum Specialty 12 oz. High Heat Satin Bar-B-Que Black Spray Paint

https://www.homedepot.com/p/Rust-Oleum-Specialty-12-oz-High-Heat-Satin-Bar-B-Que-Black-Spray-Paint-7778830/202315061Probably, although matt black would be better than satin.

-

@tletourneau I get Teflon from a local supplier, Midland Plastics. They have a commercial showroom where they sell cut-offs of all sorts of plastics and composites. When I go there, about twice each year, I always check for small Teflon scraps and buy them even if I don't have an immediate use for them. Teflon is very easy to machine and its slipperiness and moderately high temperature tolerance make it useful for all sorts of things.

Someone at the Makerspace works at a company that makes industrial electrical controls and they use a lot of Torlon. He brings bags full of cut-off pieces to the Makerspace for people to use. It's very difficult to machine, but it's very strong and withstands high temperatures.

-

@mrehorstdmd thanks! Did you tap where the bolts go into the side of the plate? Also, what size bolts did you use for the bed spring retention? If I missed it in the blog post I apologize. The plate I ordered is 3/8" thick.

-

@tletourneau If you're referring to the screws that hold the plate-end of the hold-down springs, yes, they are tapped. I used #6-32 screws. The bolts that hold the other end of the hold down springs go into the axial holes in the bed support. They are 5/16-18 tapped holes and screws.

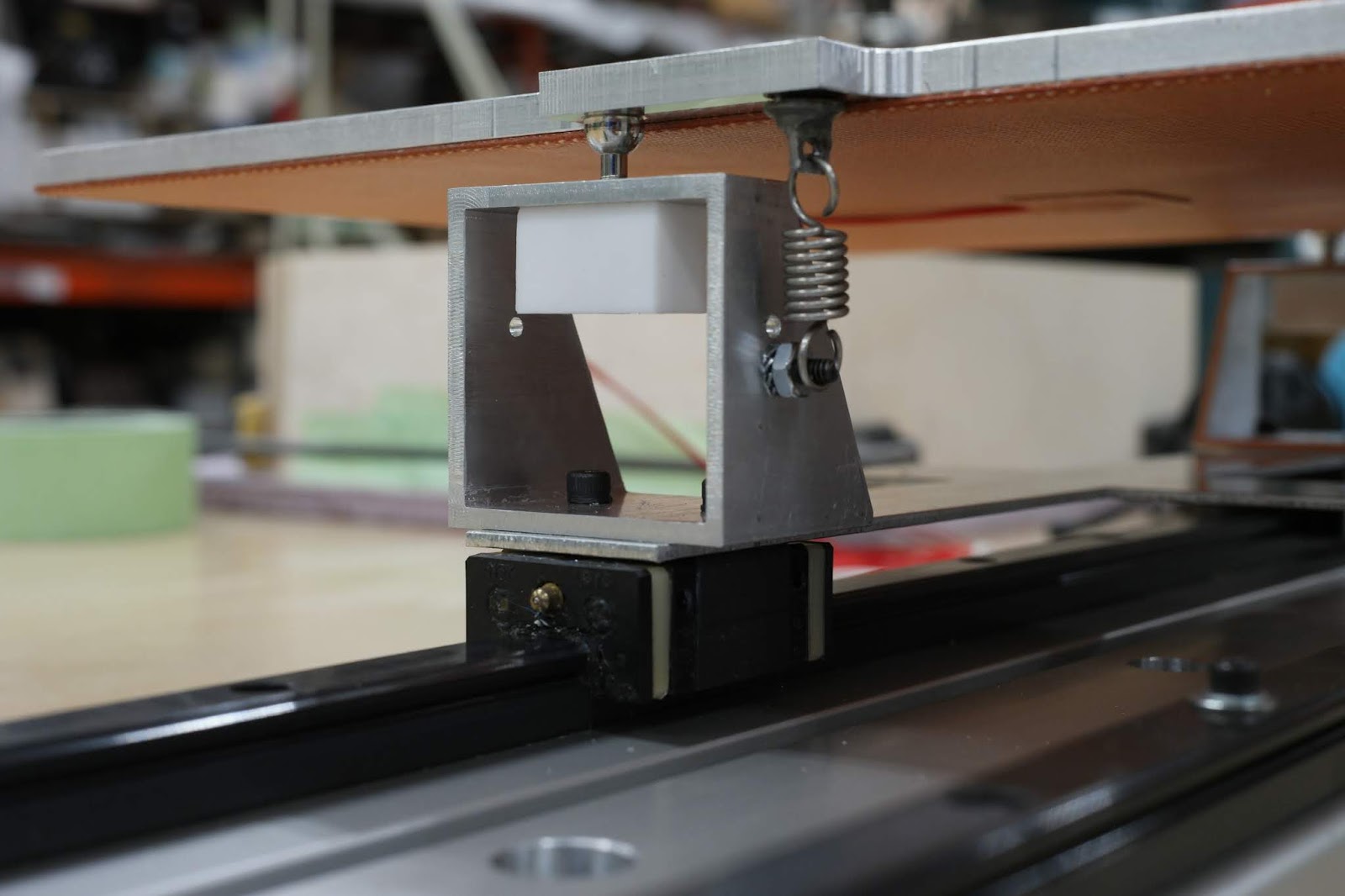

In SoM, which I recently upgraded to a line powered heater and kinematic mount, instead of drilling into the edge of the bed plate (only 1/4" thick), I made the ears wider and drilled through the plate and tapped the holes. Like this:

-

@mrehorstdmd thanks again! I'm going to try a slightly modified version of the kinematic mount. I'm going to have it mounted to 2020 with the ball screws and springs across the front and back of the plate. We'll see how it goes, the plate shipped out today so I should have it tomorrow or Monday. The heater shipped from China today as well so that should be here in a week or two (I hope).

-

So I adhered the glass to my heated bed, got it level-ish, looked closely and the bed is warped pretty badly.

713 maker just ran out of stock on the milled bed, go figure.

So the question is, should I go SSR or with the Keenevo controller? I found a 300W silicone mat (I don't need crazy heat-up times)

-

@wyvern what is the keenovo controller?

-

@phaedrux Keenovo offers an external temperature controller.

-

It's a little self-contained heat controller and timer, no wiring to the Duet at all.

The problem I see with it is the inability to set the bed temp with G-code, the upside is the reduction in wiring and since it's remote, no chance of it damaging the due... unless it decides to start on fire.

-

@wyvern I went with a SSR, I prefer to let the Duet control the temperature. It is really useful for prints like some of the ABS where I drop the bed temp after a few layers.

-

I've heard of the SSR throwing high peak voltages during SSR deactivation/off cycling.

But usually that is with shutting down actual coils- so maybe that is bad information.

-

@wyvern I'd go with a Duet controlled SSR. Something like:

https://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=288I'd worry about forgetting to turn on or off a seperate controller. Might as well let the Duet automate it with Gcode.

-

Any success with PID tuning?

-

@wyvern said in Yet another cast aluminum plate topic...:

Any success with PID tuning?

Me? Yes, I have a 310mm ish square 6mm MIC6 plate with 600w 290mm ish silicone heater RTV siliconed to the plate and SSR. PID tuning it had no issues.

-

I'll be interested in how my PID turns out. Mine will be a 500x500mm and 3/8" (9.525mm) thick ATP 5 cast plate with a 450x450mm 1000 watt 120v SSR controlled heater with a 1/4" (6.35mm) glass plate on it.

-

Keenovo sells versions of their heaters with a controller ...

https://www.keenovo.com/Keenovo-Digital-Controller-Manual.pdfI don't know what the temperature tolerance is on them but it'd seem like extra expense and just one more point of failure. I'd stick with an SSR and let the Duet control the temperature.

oops, this was a late response