Advice on adding plasma torch height control

-

About 0.5sec + 1 move.

Mhmm you're right in saying that's going to be a problem.

My plasma is remarkably forgiving in terms of crashed into the part so perhaps I'll begin with a sprung torch (to ensure it doesn't crash too hard) and focus on the other axes while I see how either modifying the baby steps/DDA goes.

Thanks once again for the help

-

@mawildoer I have always wanted a cnc plasma cutter but the cost of purchasing one was too much. Now that I have my first cnc (MPCNC), I am very keen on adding a plasma torch to it. My MPCNC is running of a Duet WiFi as well and my 3d printer (Duet V0.6). I am really happy with the Duet and a plasma system running of the Duet will be awesome. My plasma is similar to the one you have in the pic, nothing fancy like the Hypertherms. Have you made any progress? I am willing to help in any way that I can. My coding skills are basic though, only arduino projects.

-

At the moment it seems likely that I will modify the firmware to support independent Z moves controlled by some sort of PID loop in February.

-

@dc42 said in Advice on adding plasma torch height control:

At the moment it seems likely that I will modify the firmware to support independent Z moves controlled by some sort of PID loop in February.

That would be a really great feature to have and open up a lot of room for experimentation. It may also be useful to be able to override the E-Axis as well through the same system, as that would allow closed loop control of pellet or syringe based extrusion systems where maintaining a constant pressure would be highly desireable.

I know that is not the topic of this thread, but if you do actually decide to implement it for the Z-axis, opening it up to also work with the extruders would be great. I would certainly like to use a feature like this!

-

Thanks for the suggestion. I'll think about how much i can generalise the present motion system without it getting too complicated. Currently only one DDA (which represents a synchronised movement of axes and extruders) can be active at a time. I was planning to support an additional DM for just one "axis" that can move asynchronously with respect to the DDA. The PID loop would setup the required correction in that DM and wait for it to complete, before sampling again and computing the next correction. But I guess I could support more than one. Complications will arise when the system runs out of moves, or when a pause is commanded.

-

@mawildoer said in Advice on adding plasma torch height control:

EMI Testing

Just a quick update on this one. I've done some testing very specifically on the EMI induced in a shielded wire taped adjacent and in very close proximity to the plasma cable. This test cable is a CAT 6 Ethernet cable, where each pair is foil shielded and the whole cable is braid shielded.

Also note that I didn't actually conduct everything in the following order, but I thought it made more sense to present it this way.

Test Setup

I got some interesting results (and way, way more noise than anticipated).

FWIW, I've been investigating making a plasma CNC as well, and have noticed

- VERY important not to use a HighFrequency arc starting machine, these DEFINITELY will fry CNC electronics, pilot arc start are the one to use

- Many cheaper Chinese plasmas have a s*** load of EMI noise, even one page goes directly to prohibit the use of certain plasmas (including the make of the one you are testing) with their CNC frame: http://www.langmuirsystems.com/plasma-cutters

by the way, their FAQ has a load of interesting info too

For my part, I'm also investigating an inductive probe to do the z-correction, instead of Torch Height Control, because I would prefer to completely isolate the CNC from the plasma (that said, would still need to attach the torch on/off M3....), but am also worried about EMI, but directly from the arc - if the inductive sensor is to be close enough to be useful to change height at the nozzle... if the sensor gets affected, it will incorrectly change the z-height... not convinced yet that it would work, probably THC would be better as is "spot-on" the nozzle...

Cheers!

Andy

-

@andymidtf - Very interested in this topic. I'm doing a DIY CNC Plasma table and was planning to use a spare Mach3 controller. Now, I have 2x 3DPs with DuetWiFi (Duet 2 series) controllers and a spare controller. I recalled that some Duet users were using CNC router and CNC laser, so I did a quick search and found this. This post is a tad old and I'm wondering what progress you or other's have made. At the moment, I just upgraded my torch to a non-HF blowback model. Approx 4-5 years ago I tried the HF Arc Pilot torch with Mach3 and EMI was too much. So, giving this a go.. one more time.

-

undefined coseng referenced this topic

undefined coseng referenced this topic

-

I'm also wondering if there has been are work on this area, I couldn't see much in the forums about THC aside from another thread about an external controller.

Hypertherm provide some cut charts showing the sort of values expected for pierce height, pierce delay, nominal heights and feed rates. (Attached)

GDE_810050_R0_Duramax_Cut_Charts_Powermax45.pdfIn addition to their normal CNC interface (Divided arc voltage output, trigger input, arc transfer/okay output) they also have a second serial interface for additional information and control. (E.g: Mode, current set, actual current, type of nozzle) (Also attached)

GDE_810400_R2.pdfI really like the Duet3D platform and would love to use it for my upcoming CNC plasma cutter build.

-

@yngndrw Thanks for the chart.

My approach would be to use macros for different materials. Maybe we have to post-process the cut file and add information about material and thickness (global variables)

For instance, a mild-steel macro would calculate the torch height and pierce times, etc.Maybe we can use the filament folder for such settings?

-

@o_lampe My gut feeling was that, like in 3D printing, the material section would be the responsibility of the CAM (Slicer) but looking into it, it does typically appear to be the THC that has control over this.

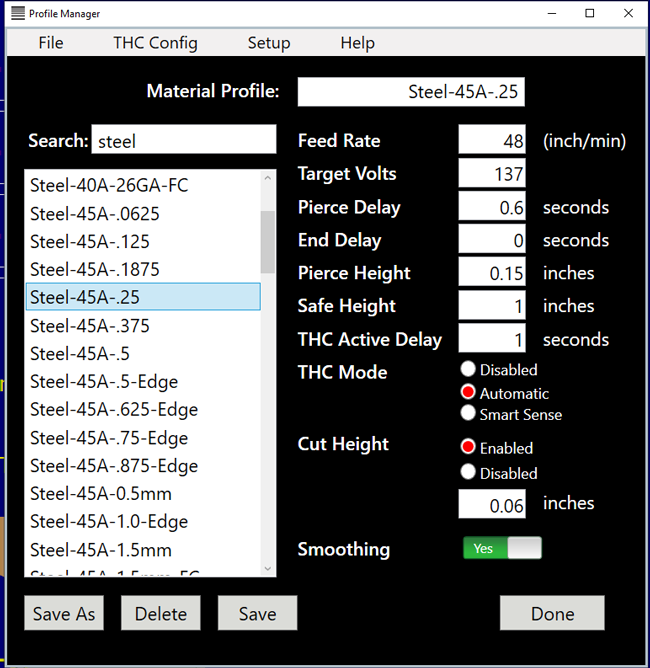

Here's a screenshot from the Centroid THC profile manager:

It's interesting because as OwenD mentioned above, the feed rate depends on the cornering so in reality both the CAM and the THC need to know about the material.

If the THC does need this information, then I think you're right that the filament system is the appropriate place.

Hypertherm do provide timing diagrams for moving piercing on the much larger systems, so I've asked if they have the same diagrams for standard piercing on smaller machines:

https://www.hypertherm.com/Download?fileId=HYP113984&zip=False -

@yngndrw

Typically on higher end systems, the cut charts are a function of the nesting software.

In Hypertherm's case they extend the cut charts you've linked to and include different feed rates for holes and small profiles, but perhaps more importantly they disable the THC during these slower moves if the feed rate is such that the resulting reduction arc voltage would cause the THC to crash the torch into the plate.Lower spec CNC systems that don't use cut charts typically have settings in the controller that might say

- Reduce speed to X% in corners

- Reduce speed to Y% for holes <Xmm

- turn off THC Xmm from end of cut

In lower spec systems, the THC is typically a separate unit and has its own settings for arc reference voltage, pierce delay, pierce height etc.

IMO, it is better to have the nesting software do all the "thinking", especially in a case like RRF where direct access to IO's etc is easy.

The "reprap" community will baulk at having to pay for commercial software and write their own post processor, but plasma cutting is not a trivial task and the various nesting software solutions have years of development in strategies for overcoming the various issues.

Whilst it's theoretically possible to have RRF do all these calculations , I have my doubts whether it could do all of it in real time.This was a small unit I spent the last week commissioning

3.5m x 1.8m. 200 amps

Pierce capacity 32mm steel.The large blue unit in the background is a fume extraction unit.

All the fumes from plasma cutting are carcinogenic.

Without fume extraction you'll fill your garage/shed with fumes in seconds.

-

@OwenD Thank you for this, it's always interesting to hear about how things are done on production systems.

I don't personally baulk at paying for software, as long as it's affordable. The issue is that sometimes the software is only priced for large industry players where there's no suitable pricing model for hobbyists. Do you have any suggestions for software at this sort of level? Sheetcam appears to be commonly used at our level, but I'm finding it difficult to work out exactly what its capabilities are as their website is rather light on detail.

On fume extraction, do you have any suggestions on what approach to go for - For a smaller, hobby-use system? The main approaches appear to be downdraft or a water table, but each appears to have serious downsides:

- Downdraft, how do you filter the air if you don't want to just dump it outside? I've not yet seen a filter design which wouldn't clog almost instantly.

- Water table, cleanup is a pain, as is the problem of stale water over time. Some people filter their water, but I'm not convinced about filter clogging for this either as the particulates appear to be extremely fine and there's very little in terms of information about the long-term performance of the various filter designs.

-

In regards to software...

All the systems I do use Hypertherm Pronest, but even the LT version is probably out of reach for "home" users.

I think a lot of people use FastCam on basic systems, but I haven't had first hand knowledge of it for about 25 years and even back then I was only running a router.

There are one or two open source projects but I have no experience with them.Fume extraction is a major issue.

A down draft table is arguably the best method but a filtered system is very expensive.

You also have to have sufficient air flow.

On higher end systems, there are internal ducts and gates along the table which open in line with the cross rail position so that all your extraction is working on where the torch is.

Cheaper systems just have a tube entering one end of the table, however this means that you have to have a fan big enough to move the required air velocity across the entire bed area.

Typically they work "ok" while a full sheet covers the entire bed area and almost not at all if there are open spaces.Water tables work quite well but have their own issues.

The water has to be treated to stop algae, rust etc and has to be changed (and disposed of) regularly.

Putting it down the storm water drain is likely illegal in most places.

Parts fall in and are hard to find.

It oxidises aluminium parts quickly.

If you are cutting aluminium there is a risk of a build up of hydrogen gas under the sheet as the fine aluminium dross reacts in the water.

All the O2 is stripped out leaving only hydrogen.

Whilst I've seen bubbling on many systems, I've only experienced one case of it igniting. That one made a huge bang and lifted a 20mm plate of aluminium off the table. -

@OwenD In my case, Im' building a mobile water bed cutter with foldable extensions.

The torch will only move in X-direction (and Z) but the sheet will move in Y. Like a good ol` bedslinger.

If I have to cut alot, I'll roll it outside.My plasma cutter is a simple Parkside 40A device with integrated compressor. No intelligence there.

I have to set amps manually and hope for RRF to do the thinking. Steady speed is the key, I guess. -

@o_lampe

Presumably you are only planning on doing small "sheets"

Can't see how a "bed slinger" will work with the masses involved otherwise.

Even so, a cantilever style arrangement is more the norm on low spec systems as it's light, simple and has a small footprint.

If the parts cut are small and the sheets well supported, then a THC that uses arc voltage control (AVC) is not critical.

You just need initial height sensing much like a normal Z probe.

The plasma power source doesn't need any smarts.

If you're using AVC then a CNC interface that has a voltage divider is usual and it's best if the unit can supply an "arc established" signal.

If RRF is measuring it directly then you'd need a 50:1 or 100:1 divider I think.

At 40 amps the arc voltage will likely be less that 150 volts on most thicknesses, but voltages up to 170 volts or so are possible. -

@OwenD Thanks for the software suggestions, I'll have a look into those.

I wasn't aware of the explosion risk with aluminium and water, that's good to know. What filtration systems do the industrial downdraft systems use? I'm wondering if a DIY version can be made for a smaller work area with sufficient flow.

@o_lampe I don't know if this is any help for your project but I always try to start designing around the bits I want to buy in. In my case that's the magnetic breakaway torch holder (I have not found one yet) and the water table (As I have zero confidence that my welds won't leak!)

For the water table I've been looking at these 1000x500x40mm stainless trays:

https://www.amazon.co.uk/dp/B0CFV84HZG/?th=1... Along with these packs of slats:

https://www.ebay.co.uk/itm/196266001091I'd rather use a taller water table, but it's the right size for the pre-made slats to have a slight curve. My plan was to add a slotted angle frame on the inside to hold the slats and they are easy to replace with off-the-shelf items.

Moving a bed, complete with water, doesn't sound like fun. Aside from the mass, you'd also have to deal with the sloshing.

-

@OwenD said in Advice on adding plasma torch height control:

Presumably you are only planning on doing small "sheets"

Can't see how a "bed slinger" will work with the masses involved otherwise.It's a bad idea, I know.

A thicker sheet wil be cut at slower speed than a thin sheet. I'm not sure which is worse to toss around?

Especially when acceleration is low, the cut quality in thinner sheets wil show significant differences.@yngndrw said in Advice on adding plasma torch height control:

Moving a bed, complete with water, doesn't sound like fun. Aside from the mass, you'd also have to deal with the sloshing.

I'm doing the trick with a submerged inflatable tire-tube to lower the water level for transport. It's also the easiest way to adjust water level while cutting

-

@yngndrw

I think that 40mm is too shallow for a water table even at 40 amps

The compressed air will blow it out.

You'll need to look at 100-150mm in depth.

If the air pushes aside the water all the way to the bottom it won't trap any fumes. Plus it'll splash everywhere.Industrial filters capture particles small enough to directly enter the blood stream via the lungs.

It's not just dust, there are factors such as hexavalent chrome etc.

You should read here for a start

https://www.kemper.eu/en/worth-knowing/welding-smoke-regulations-and-legistlation/1.-overview

The KEMPER filters for cnc tables have a self cleaning system as well.As far as slats go, all they have to be is ordinary flat mild steel. 50 x 3 would suffice. If they're 76 or 100 you can flip them as they are damaged.

The usual arrangement is the have three vertical pieces of flat running lengthways down the table.

These have slots in them about every 50mm.

When you put your slats in, you bend them in a curve so that the middle is 50mm further up than the ends.

This stops cross cuts being on top of a slat for long.

All the slats can then be the same length. -

@o_lampe said in Advice on adding plasma torch height control:

@yngndrw said in Advice on adding plasma torch height control:

Moving a bed, complete with water, doesn't sound like fun. Aside from the mass, you'd also have to deal with the sloshing.I'm doing the trick with a submerged inflatable tire-tube to lower the water level for transport. It's also the easiest way to adjust water level while cutting

I mean when the bed is moving, not when you're transporting the machine. Unless it's moving really slowly, the water will be sloshing out whenever it changes direction.@OwenD said in Advice on adding plasma torch height control:

@yngndrw

I think that 40mm is too shallow for a water table even at 40 amps

The compressed air will blow it out.

You'll need to look at 100-150mm in depth.

If the air pushes aside the water all the way to the bottom it won't trap any fumes. Plus it'll splash everywhere.Industrial filters capture particles small enough to directly enter the blood stream via the lungs.

It's not just dust, there are factors such as hexavalent chrome etc.

You should read here for a start

https://www.kemper.eu/en/worth-knowing/welding-smoke-regulations-and-legistlation/1.-overview

The KEMPER filters for cnc tables have a self cleaning system as well.As far as slats go, all they have to be is ordinary flat mild steel. 50 x 3 would suffice. If they're 76 or 100 you can flip them as they are damaged.

The usual arrangement is the have three vertical pieces of flat running lengthways down the table.

These have slots in them about every 50mm.

When you put your slats in, you bend them in a curve so that the middle is 50mm further up than the ends.

This stops cross cuts being on top of a slat for long.

All the slats can then be the same length.

Ah that's good to know, I suppose I'll have to make my own deep water table then.I did look at water scrubbers for a downdraft table after realising how simple they are, but then I realised the airflow requirements are silly even for a modest table. For a 0.5 square meter table, Hypertherm is suggesting over 3000 cubic meters per hour which is an order of magnitude larger than "metal dust collectors" I can find. It's therefore unreasonable to try to move that volume of air, especially if you're trying to filter it to say 1-3 microns. In fact, it gets to the point where the downdraft fan motor draws more power than the plasma cutter, which added to the air compressor will be too much for my workshop. Hexavalent chrome appears to require 5-micron filtration and I'd really like to be able to work with stainless, so I think the water table option is more reasonable.

I'll probably aim for a tray depth of 150mm and a water/slat level of 100mm to prevent splashing. I just need to work out how to build it.

-

@yngndrw said in Advice on adding plasma torch height control:

I just need to work out how to build it.

Maybe that's the right time to start a build-thread in CNC and keep the OT down?

My build is not very far, but I'm willing to discuss it.

I've used silicone to seal the water tank. A splash guard all around the top will also help and the partly submersed vertical slats will break the waves.