Delta Calibration while Hotend Fan on

-

I am using a Smarteffector V4 along with a Duet 3 Mini5+ with RRF firmware 3.4.6

When I do a G32 with a cold hotend everything goes well with a deviation of 0.012mm.

But If I do a G32 with a HOT (150 C) hotend I get a lot of false reading registering contact with the nozzle still on air. But If I unplug the hotend fan, everything seems to go fine.

I have shielded with copper foil all cables, but as soon as I plug the fan again, everything goes crazy. The fan is a GDSTIME GDA2510 12V 0.06A.

If I use a GDT2510 12V 0.8A fan it seems to behave. But unfortunately I broke the one that I had, so I need to keep trying. How can this be?

I am defining the fan as follows:

M950 F1 C"out5" Q250

M106 P1 S1 H1 T45How can I solve this? I have several GDSTIME 2510 fans available, but none works

-

You can try turning the heater and fan off during probing. As it is thermostatically controlled you'd need to set it to manual control before probing, and return it to thermostatic afterwards in your homing macro.

-

@Phaedrux Yes, but with other fan brands and sizes, it gave no interference at all. What can be the cause here? Is it related to the "Q250" PWM parameter?

For example, I have noticed the problematic fan is "12V 0.06A" while the "good one" is "12V 0.8A"

It surprisingly needs 15 times more current...

With all the wires shielded I expected not to have any problem, but I keep having them.

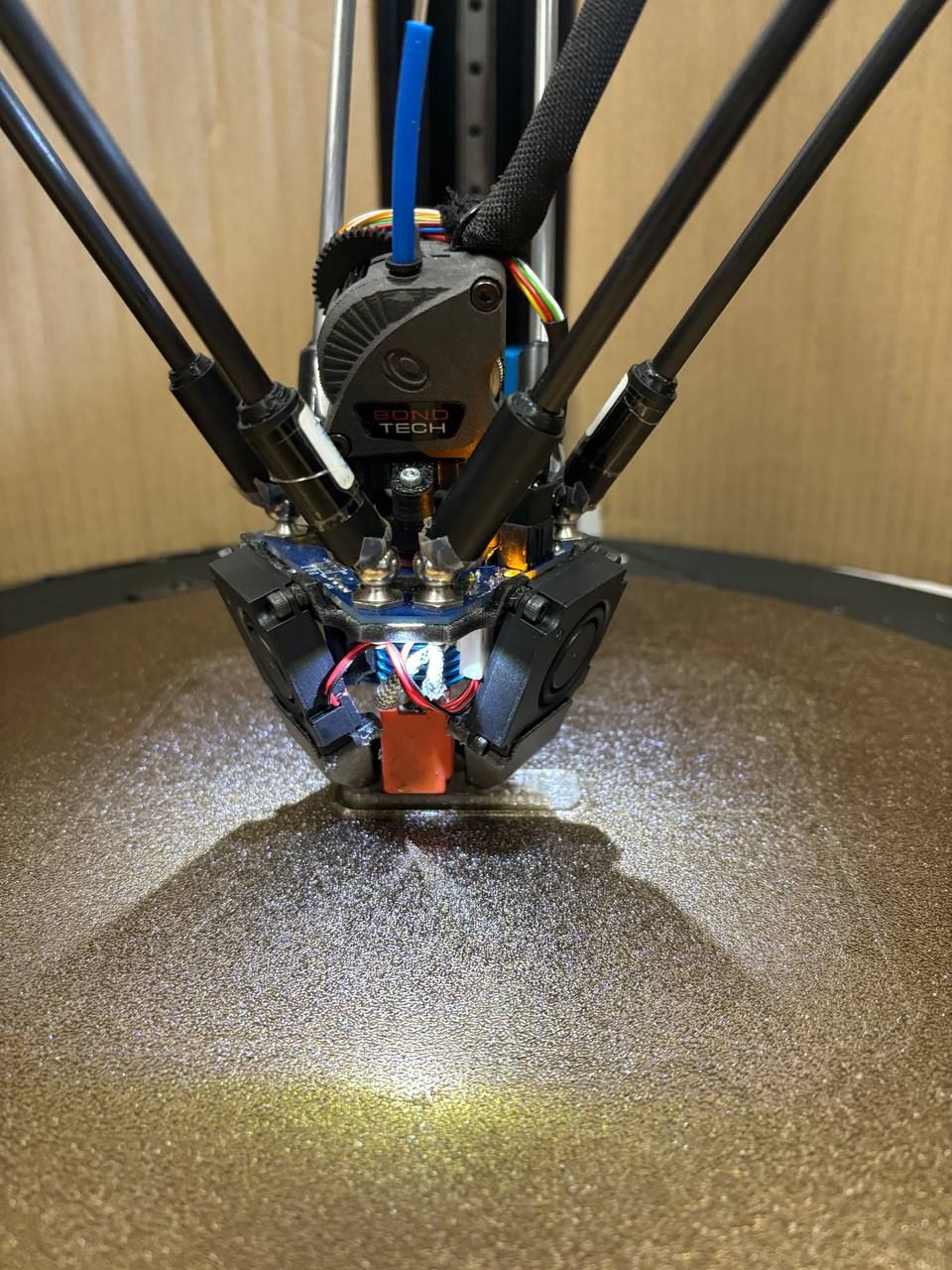

Should I wrap the fan body with copper foil?I have made the following test: I unbolt the fan, leave it resting on the top of the extruder connected and spinning and G32 works ok. Could this be the magnetic field of the fan motor?

I am surprised of Smarteffector being that sensitive.....The 24V 50W hotend heater wires ran initially almost touching the bottom side of the smarteffector and they didn't seem to affect it at all while probing with the hotend heater on. How can the position of a fan so small be so critical?

-

@ignacmc the Smart Effector measures signals of a few tens of microvolts when the nozzle touch the bed and applies strain to the effector. This makes it sensitive to signals induced by varying magnetic fields. We've done our best to minimise the area enclosed by the strain gauge traces so that magnetic fields have minimal effect, but there's only so much we can do. What's happening is that the fan you are using is producing a greater varying magnetic field outside the fan than typical hot end fans do.

The Q parameter is only relevant when the fan is running at less than full speed. The M106 command you posted above instructs the fan to run at full speed whenever the hot end temperature is 45C or greater. Running the fan at less than full speed would produce a greater magnetic field.

The only type of shielding that would be effective is magnetic shielding using mumetal or similar. That's expensive and heavy. So the best approach is to use a better fan. BTW a fan that produced a lot of magnetic field on the outside is likely to be less efficient than one that keeps the magnetic field contained within the fan.

I guess you could try disabling the fan during probing, by using a M106 command in deployprobe.g to turn the fan off, and restoring the thermostatic function in retractprobe.g.

-

@dc42 I have just ordered different 2510 fans to see if I am lucky and they make a difference. Aternatives to GDSTIME for that size are not easy to find....

I have also thought of wrapping the fan case with a very thin nickel strip (the ones used for spot welding 18650 batteries...will try tonight and report

Configuration-wise....Is there something I could do by lowering the speed or changing PWM frequency? You tell me I will generate more magnetic field by running slower? Is this correct?

-

@ignacmc applying PWM to run the fan slower will probably make matters worse, because then the PWM will itself generate varying magnetic fields.

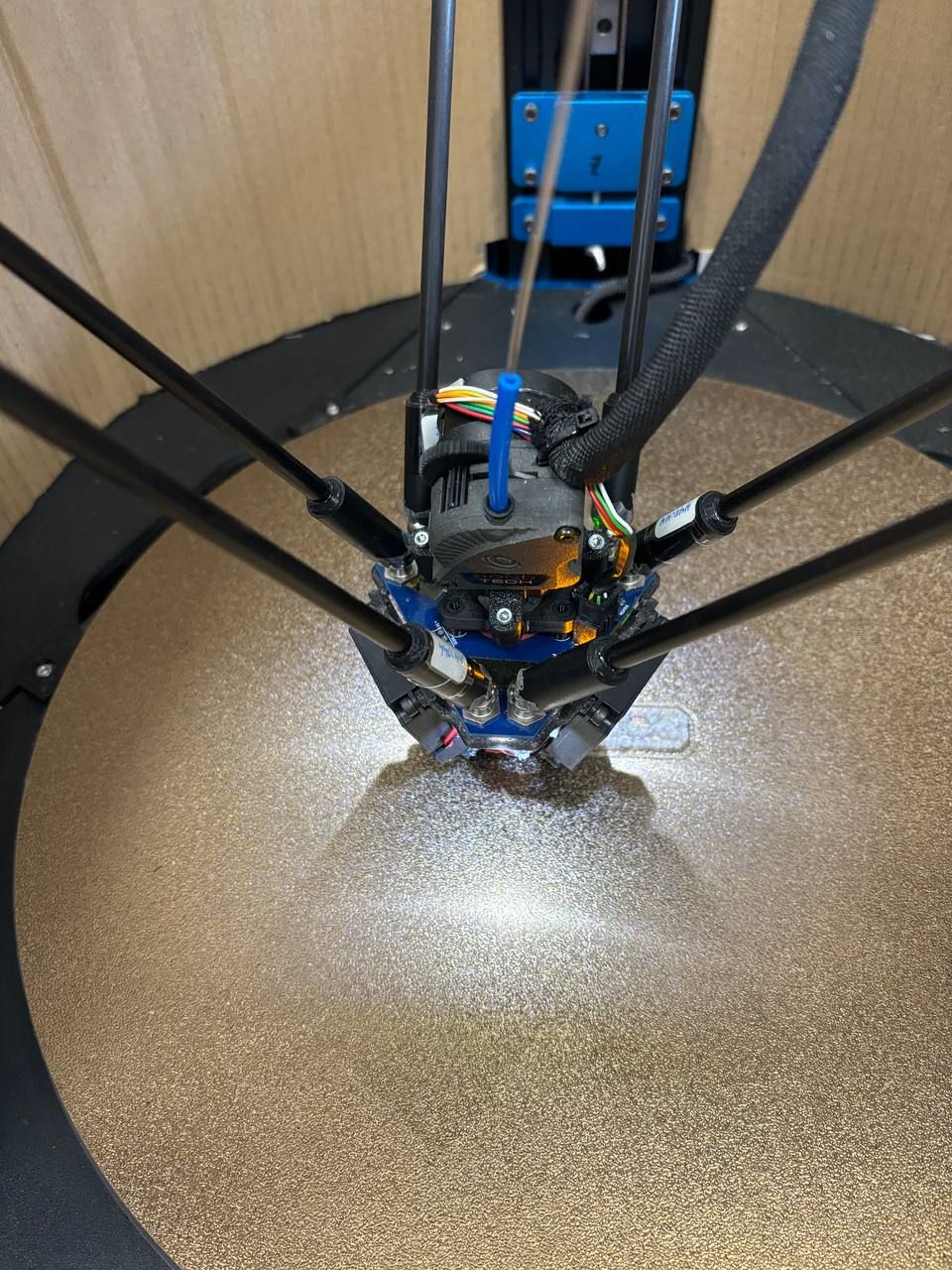

Is the hot end fan especially close to the Smart Effector PCB in your setup?

I use a E3D Revo hot end and fan with my Smart Effector, and before that I used a E3D V6 hot end and fan. Neither gave me any problems when probing hot with the fan running.

-

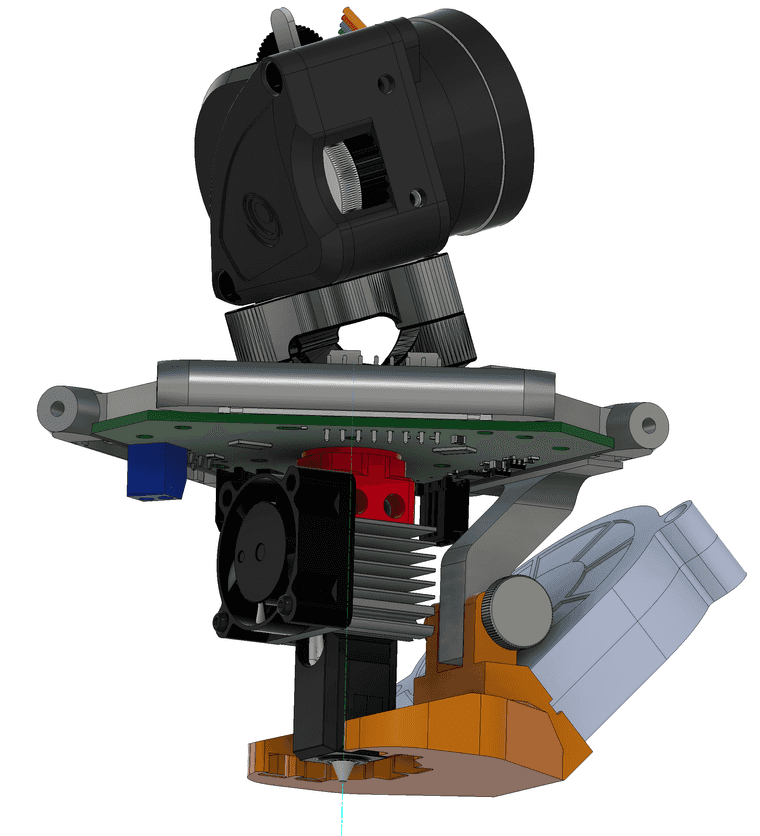

@dc42 Yes. I was happily living with a SmartEffector v2 + E3Dv6 and zero fan problemas when I decide to change the whole toolhead to something more actual: SmartEffector v4 + Bambulab clone:

Here the problems started.....

Curiously I was concerned about the heater cables being very close to the PCB, but it didn't seem to affect it at all

-

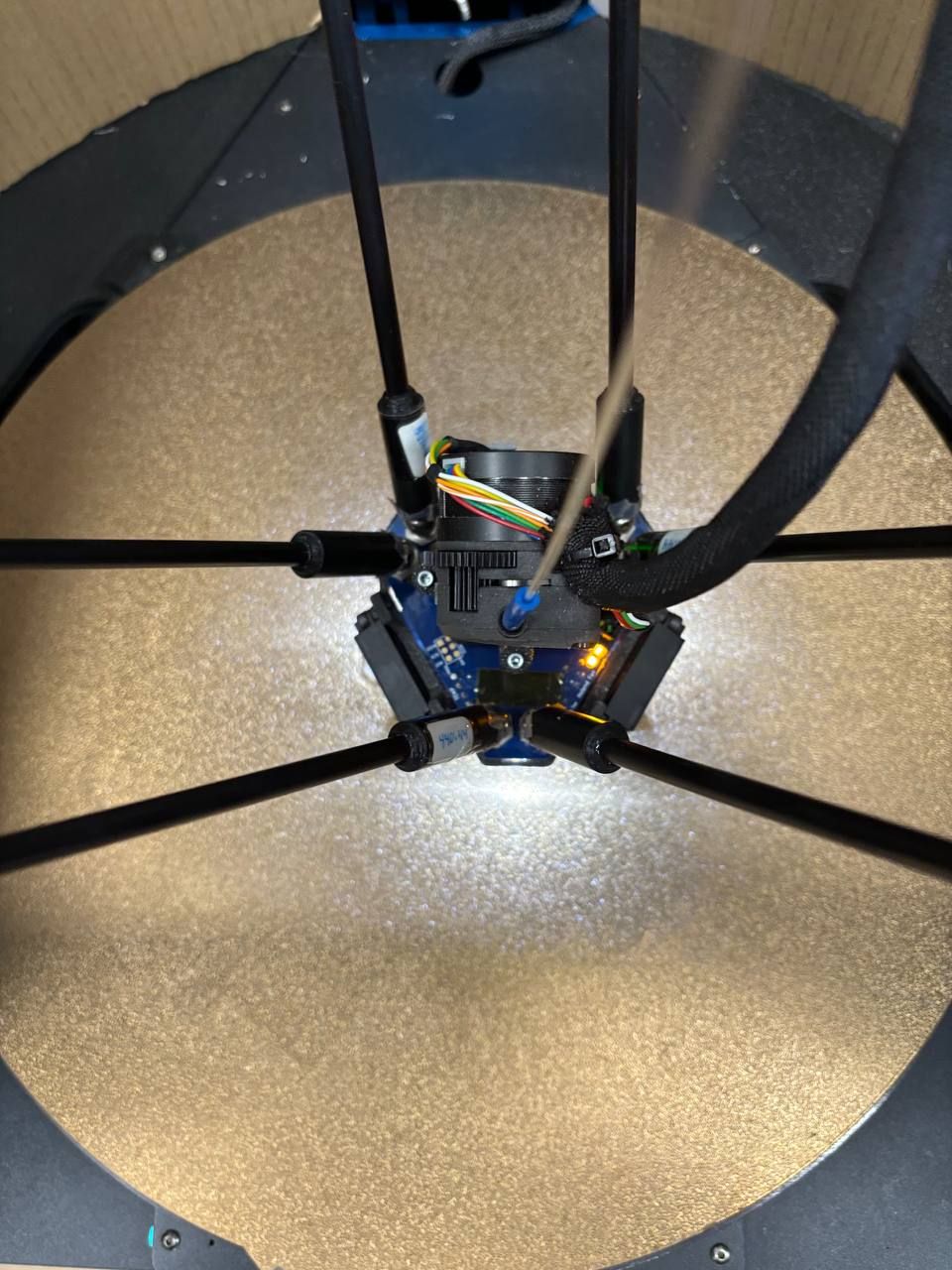

@ignacmc make sure your arms are set in couples and positive oposite to negative on the 6 magballs og the effector, also use nylon spacer and make sure the screws don´t touch the pcb...

on my pictures you can tell by the lenght stickers on the arms and no label on the others.

By doint this wou balance the magnetic fields, other than if you put all 6 positives on one side and all 6 negatives on the other side.

Don´t mind the "stickers" on the magball to arm joint section, it´s a 0.8mm ptfe film to lubriocate the joints

-

@apak I am not using magnetic arms. Made a design in Fusion 360 based on one very similar that found on Thingiverse and then had it printed in ALUMINUM in China. Made the M3 threads manually.

But thank you very much for this info that I will keep should i ever go the "magnetic way"

-

@ignacmc this is the way!!!!!

-

@apak What is this? hahaha.... Any real printer or mod?

-

@dc42 Changing to another 2510 fan (Sunon brand) solved all problems. Who could have imagined? I shielded all cables in vain

-

@ignacmc I'm glad you got it working. The other fan just have generated a particularly large magnetic field external to it.

-

undefined dc42 marked this topic as a question

undefined dc42 marked this topic as a question

-

undefined dc42 has marked this topic as solved

undefined dc42 has marked this topic as solved