Maximum F speed for Duet 3 6HC

-

Hello I am running a duet 3 and trying to go to F16000 for one of my extruders. I have a two in one out extruder so each motor is rated for F8000 with no micro stepping.

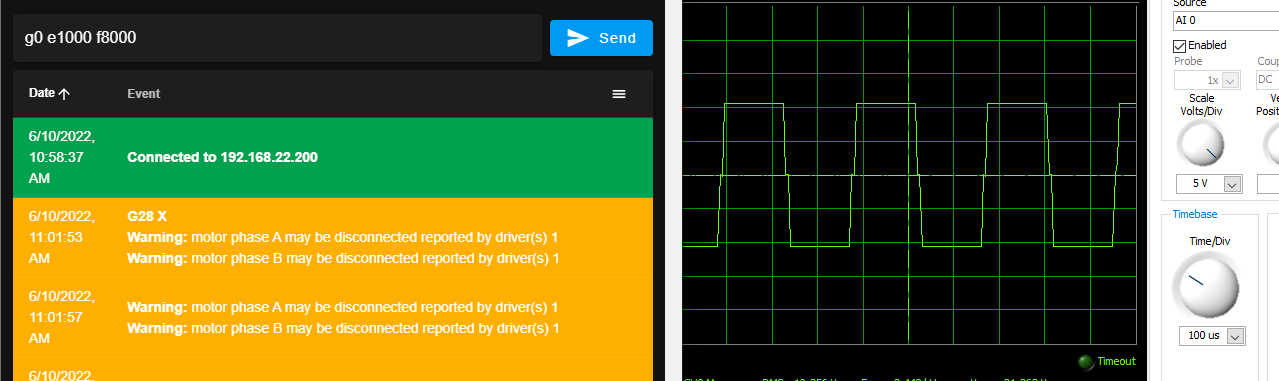

when I run the motors they ran oddly so I looked at the duet's signals form the pins to the motors and noted at about F13710 it would begin to have warped duty cycles

here is a photo of a G1 E1000 F8000

and here is a photo of G1 E1000 F16000

I am not sure why it is doing this, is this a limitation of the drivers? am I approaching the limit of the TMC5160? is there a demon eating my pulses?

any help will be appreciated

-

@payton You need to post your config.g file (without it there is no way to know what the Fxxxxx numbers translate to in terms of steps/s). It would also probably help if you post the specifications of the stepper motors you are using and the voltage you are running them at.

-

the motor is a bit weird but it is not important for this problem. it will be difficult to get the Motor specs

-

M584 X0.1 Y0.2:0.3 Z0.4 E0.0:0.5 ; set drive mapping M350 X16 Y16 Z16 E1:1 I0 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E207:207 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E30000.00:30000.00 ; set maximum instantaneous speed changes (mm/min) (jerk settings) M203 X6000.00 Y6000.00 Z600.00 E50800.20:50800.20 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z120.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent ; Tools M563 P2 S"Viscotec" D0:1 ; define tool 2 ( Drive 0.0: Drive 0.5) G10 P2 X-72 Y-98.1 Z-15.15 ; set tool 2 axis offsets G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C M567 P2 E0.5:0.5This is a bit of a strange setup. What more can you tell us about the motor and extruder?

Firmware version?

-

@payton said in Maximum F speed for Duet 3 6HC:

it will be difficult to get the Motor specs

Ask them: mail@viscotec.de

-

@phaedrux said in Maximum F speed for Duet 3 6HC:

This is a bit of a strange setup. What more can you tell us about the motor and extruder?

I too am curious to know how or why one would want to run an extruder at a filament feedrate of approximately 300 mm/sec. Which equates to a melt rate of around 700mm^3/sec.

-

@infiniteloop we have had a problem with the motors before, but they will not give or don't have a datasheet for the motors as far as I am aware. however the problem is for sure with the signals coming from the duet board having gaps in the duty cycle

-

@phaedrux

m115

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.0 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2022-03-15 18:57:26

the problem is not with the motor but with the signals from the duet. -

@infiniteloop

this is the best I have received and it is configured completely differently. this uses an 8 pin connector or a can bus. but the Viscotec uses a 4 pin setup, two to live and neutral 24V, and 2 to the motor pins of the duet. it uses the duet's motor pin signal to command an internal driver witch runs the servo. -

however the problem is for sure with the signals coming from the duet board having gaps in the duty cycle

It is always problematic to point with the finger on someone when the other party is completely unknown. Like any other device, Duets and the used ICs have technical limitations, maybe resulting in the „gaps“ you describe at extreme frequencies. Either you lower extrusion speed, or you set up some kind of frequency doubler - which might be tricky as long as the kind of signals required by the extruder is unknown.

-

@payton said in Maximum F speed for Duet 3 6HC:

this uses an 8 pin connector or a can bus. but the Viscotec uses a 4 pin setup

Then, it's useless. Did you ask Viscotec for technical data? If they want to make business, they should really be interested to tell you how to control their devices.

-

Can you provide a M122 report after you've commanded the rapid extruder movement?

-

@infiniteloop if it is a hardware limit I am bumping up against is what I am trying to ascertain. if it is a hardware issue I will need a different board, if it is some config issue, then I do not

-

@payton it's a bit old now, but from https://docs.google.com/spreadsheets/d/1AWA1wLbOaYzxzdQa5LRZvn9rgEk2BuluHy6-_OnD6FY/edit#gid=0 you can see that we have achieved 650kHz step rate on the 6HC with a single motor running, and 480kHz with 3 motoes running,

-

@payton it looks like you are operating the drivers with "fast" step pulse timing, which is the default for internal Trinamic drivers. This means the step pulses are only guaranteed to be long enough for the built in drivers to register a step.

External drivers generally need a bit of a longer step pulse. Now your motors are an odd design which use the stepper driver output to driver another driver. when a motor is connected the slight differences in step pulse length when stepping quickly makes no difference, but if you want the steps to be evenly spaced then try using the T parameter to extend the step pulse width (try T1).

You will observe however that if you go two fast the firmware will group step pulses together in batches which once again is a variable duty cycle however maybe your drivers wont mind that behaviour.

As far as step rate itself is concerned, with T1 you should be able to reach 300Khz, looking at your requirement (207 steps/mm at F16000 = 266.66 mm/s) of 55.3Khz step rate, this is very achievable.