Issues with pressure advance since RRF 3.4

-

@paanjii2

All details are in this thread and in this one: https://forum.duet3d.com/topic/26062/3-4-0beta7-new-input-shaper-disturb-pressure-advance

If you want any specific information please ask.

-

@gloomyandy that is correct, didn't see a difference.

-

@argo this is close to the top of my list to look into. What's a good print to test this on - is a hollow square tube sufficient?

-

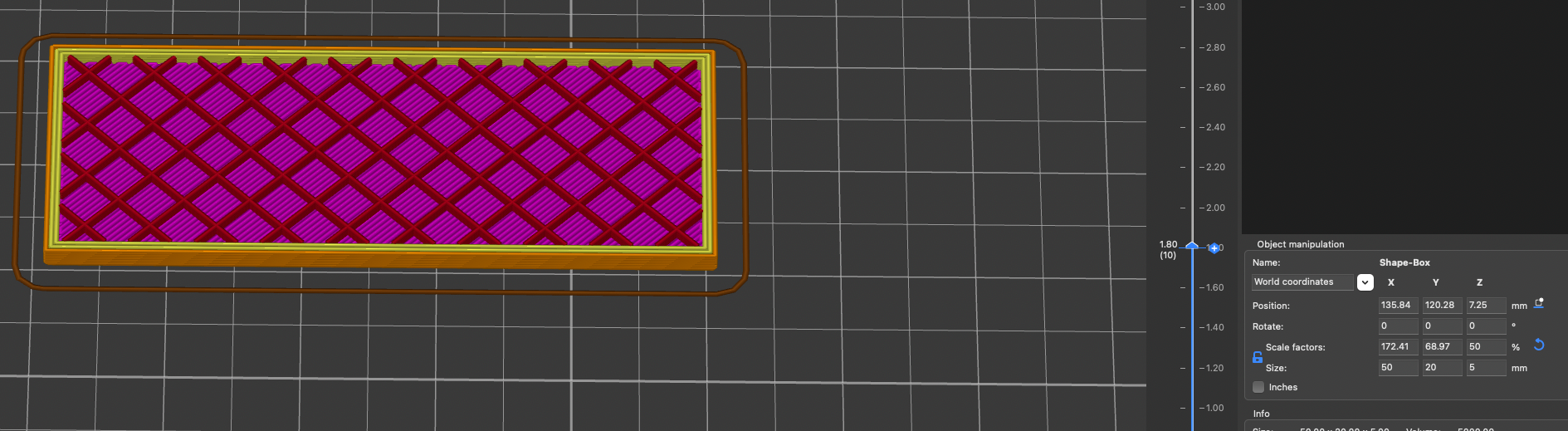

You could just create a shape box in Prusa Slicer (or similar slicer that can generate shapes) with the following measurements:

X: 50mm

y: 20mm

Z: 5mmPerimeters: 3

Top Layer: 0

Bottom Layer: 4

Infill: Grid 20%

Layer time goal: 0s (so it does not slow down the print)My speed settings: https://forum.duet3d.com/post/288649

If you are using a direct drive extruder with PLA a PA value around 0.055 is usually a good value.

I would not print it hollow so you can compare the quality of infill lines and corners.

The issue I'm having is healthy infill lines and bulging corners or sharp(ish) corners but starving infill lines (example in this posting: https://forum.duet3d.com/post/288686).

-

I confirm there is an issue with pressure advance in RRF 3.4. It works better in 3.3 but I think it is still not quite right. We'll issue another 3.4.2rc release when we have fixed it.

-

Further to my previous message: I made a mistake in my test program. Currently I can't see any difference in how PA behaves between 3.3 and 3.4 with input shaping disabled. I will investigate further next week.

-

@dc42 Try it with input shaping enabled. A problem people are having is tuning PA after enabling IS.

-

@ctilley79 before I look into the interaction of IS and PA, I need to understand why some users are reporting that even with IS disabled, PA behaves differently in 3.4 compared to 3.3.

-

@dc42 Could you share any of your test methods? Im currently just plotting step/dir signal outputs.

-

I've been debating whether or not to comment on this thread for weeks as I'm hesitant to blame PA for the print artifacts I've been seeing, but after a lot of testing it seems to be the culprit. It's possibly I'm still getting through some acceleration/jerk tuning stuff or I still need to play with belt tension and/or IS. However, since going from 3.3 to 3.4 on my voron 2.4 build with a Duet wifi 2, I have been seeing odd bulging behaviors on roundish perimeters, or with embossed text. I can post some pictures later of some examples. I sometimes see sections that are supposed to be straight end up with a gentle concave curve.

Again, it could be that I'm just new to tuning Core XY systems, or my external stepper driver setup not being super robust, or something else entirely, but it feels like I've spent a lot of time working out print artifacts on this machine to get close to what I'd consider a perfect FDM part.

-

@michaelr123 I am interesting in seeing any differences in the effects of pressure advance between RRF 3.3 and RRF 3.4.x with input shaping not used. [There is a separate discussion on the interaction of PA with IS.] Ideally with a quick-to-print example (e.g. just a few layers high) that demonstrates the difference.

-

@dc42 totally understand, we need to narrow down whether it's 3.3 to 3.4 that causes issues for PA specifically. I think my comments are more along the lines of it's been tricky to tune a coreXY on 3.4 so far. I need to try rolling back to 3.3 yet as I've been on 3.4 for awhile now.

-

@dc42 said in Issues with pressure advance since RRF 3.4:

Ideally with a quick-to-print example (e.g. just a few layers high) that demonstrates the difference.

I notice the difference with a simple hollow cube with 2mm thick walls. The corners bulge more in 3.4 and the extruder sounds different. I had to lower e jerk to prevent gaps and reduce the noise. e jerk went from 3000 to 1500. PA only 0.025.

-

Now things are getting complicated.

I have another printer which is a Bear Bondtech Mk3 bedslinger (originally was a Prusa Mk3s).

When I compare corners with RRF3.3 to RRF 3.4 there are hardly any differences. RRF 3.3 is a bit better but RRF 3.4 is not as worse as my previous results with the CoreXY (Voron 2.4) machine.So what's different between those two printers.

The printer (Voron 2.4) having difficulties with bulging corners and RRF 3.4 differs in three things compared to the Bear Mk3:- it's a Core XY machine

- prints perimeter double the speed

- uses a Duet 1LC toolboard V1.2

Maybe this helps somehow...

-

@argo it's entirely possible that there could be a bug that affects PA when the extruder is driven by a CAN-connected expansion board that is not present when it is driven by the main board, because different code is used. I will do some more tests with the extruder driven by a tool board.

Yesterday I did comparative tests between 3.3 and 3.4 using 120mm/sec perimeters, 160mm/sec infill and PA 0.4. The results were very similar. Extruder was driven from the Duet 3 Mini.

-

I bet your to-do list is quite full and time is limited but when you find the bug and did a possible fix to the firmware feel free to upload the compiled firmware for me/us for testing.

I've seen you did this before and uploaded the files to a Dropbox folder. -

Results are still unchanged with RRF 3.4.2rc2.

PLA, PA set to 0.057:

-

@argo please can you provide a small GCode print file that demonstrates the issue, along with the config.g file for the machine concerned, and details of the extruder (especially the length of the Bowden tube). A print file that does the print in the photo you posted above (and stops after a few layers as in the photo) would be suitable.

-

Yes, sure.

Extruder is a LGX (not the lite version) with a Rapido HF Hotend.

The bowden tube length between the extruder gears and the hotend is about 15-20mm long.

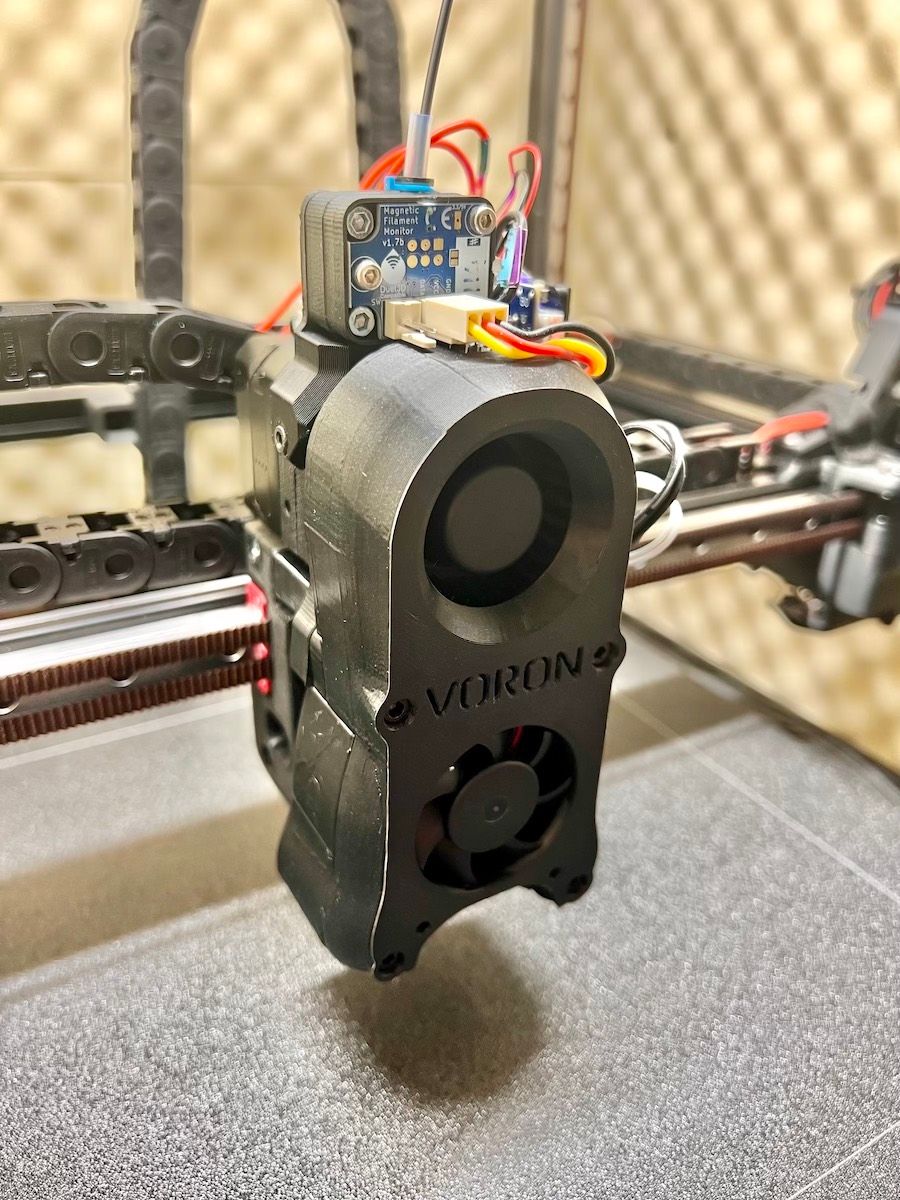

Printer: Voron 2.4 - 300mmPhoto of the printer:

Config.g:

G4 S1 ; wait 1s for expansion boards to start ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"Walross" ; Set machine name M552 S1 ; Enable network ;*** Access point is configured manually via M587 M586 P0 S1 ; Enable HTTP M586 P1 S1 ; Disable FTP M586 P2 S1 ; Disable Telnet M575 P1 S1 B57600 ; Panel Due ; Printer geometry M669 K1 ; Select CoreXY mode M208 X0:290 Y-3:300 Z-0.2:270 ; Axis Limits M564 H0 ; allow unhomed movement ;------- drives from top--------------------------------------------------- ; B -------+------ A ; | P.02 | P.03 | ; -------+------- Z-Drives ; | P0.1 | P0.4 | ; -------+------- ; Front ; Drive Mappings M569 P121.0 S0 D2 ; Drive 0: E Axis M569 P0.1 S1 D2 ; Drive 1: Z-LeftFront Axis M569 P0.2 S0 D2 ; Drive 2: Z-LeftRear Axis M569 P0.3 S1 D2 ; Drive 3: Z-RightRear Axis M569 P0.4 S0 D2 ; Drive 4: Z-RightFront Axis M569 P0.5 S1 D2 ; Drive 5: Expansion: B motor (X-axis) M569 P0.6 S0 D2 ; Drive 6: Expansion: A motor (Y-axis) ; Motor remapping for dual Z and axis Limits M584 X5 Y6 Z1:2:3:4 E121.0 ; Motor mapping M671 X-60:-60:360:360 Y-10:370:370:-10 S20 ; Z leadscrews positions Left Front - Let Rear - Right Rear - Right Front ; Microstepping and Speed M350 X32 Y32 E16 Z32 I1 ; Configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E400.00 ; Set steps per mm 1.8 motors ; Speeds, Acceleration and Jerk M566 X300.00 Y300.00 Z25.00 E400.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X24000.00 Y24000.00 Z900.00 E1200.00 ; Set maximum speeds (mm/min) ; SpreadCycle M201 X5000.00 Y5000.00 Z1000.00 E5500.00 ; Set accelerations (mm/s^2) ; SpreadCycle ; Motor currents M906 X1250.00 Y1250.00 Z1100.00 E700.00 I55 ; Set motor currents (mA) and motor idle factor in percent M84 S30 ; Set idle timeout ; Endstops for each Axis M574 X2 S1 P"io1.in" ; Set X endstop controlled by switch M574 Y2 S1 P"io2.in" ; Set Y endstop controlled by switch M574 Z1 S2 ; Set endstops controlled by probe "OLD" VINDA ;M574 Z1 S1 P"io6.in" ; Z endstop switch ; Stallgaurd Sensitivy (maybe use to pause print after crash) M915 X S2 F0 H200 R0 ; Set X axis Sensitivity 1.8 motors M915 Y S2 F0 H200 R0 ; Set y axis Sensitivity 1.8 motors ; Input Shaper and Accelerometer ;M955 P121.0 I05 ;Accelerometer ;M593 P"zvdd" F46 S0.05 ; Z-Probe M558 P8 C"121.io2.in" I1 H2 F250:100 T6000 A500 S0.0025 ; VINDA ; Mesh Grid M557 X5:260 Y30:250 P7 ; ; Z Probe Offset (Probe behind Afterburner) ;G31 P1000 X0 Y25 Z1.095 ; VINDA - 3Djake Nano G31 P1000 X0 Y25 Z0.770 ; VINDA - 3DSWay Textured ; Filament Runout sensor M591 D0 P3 L25.95 E3 R10:250 C"121.io1.in" S1 ; Filament Sensor ; Heatbed Heaters and Thermistor Bed M308 S0 P"temp0" Y"thermistor" T100000 B4725 C7.060000e-8 ; Heatbed Thermistor M950 H0 C"out0" T0 Q10 ; Creates Bed Heater (SSR) M307 H0 R0.889 K0.762:0.000 D3.02 E1.35 S0.6 B0 M140 H0 ; Bed uses Heater 0 M143 H0 S116 ; Set temperature limit for heater 0 to 115C Bed ; HotEnd Heaters and Thermistor HotEnd M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor M950 H1 C"121.out0" T1 Q100 ; Create HotEnd Heater M307 H1 R4.568 K0.683:0.000 D4.04 E1.35 S1.00 B0 V24.4 ; PID as heater M143 H1 S295 ; Set temperature limit for heater 1 to 285C HotEnd M302 S15 R15 ; min extrusion (cold extrusion) temp ; Fans Hotend + Part M950 F3 C"121.out1" Q100 ; Creates HOTEND Fan M106 P3 T65 L1.0 X1.0 H1 ; HOTEND Fan Settings M950 F0 C"121.out2" Q100 ; Creates PARTS COOLING FAN M106 P0 H-1 ; Parts Cooling Fan ; Fans Electronic compartment & Exhaust M950 F1 C"out3" Q100 ; Creates Case Fan 1 M106 P1 T40 S170 L170 X170 H0 ; Case Fan 1 Settings M950 F2 C"out4" Q100 ; Creates Case Fan 2 M106 P2 T40 S170 L170 X170 H0 ; Case Fan 2 Settings M950 F5 C"out5" Q100 ; Creates Exhaust Fan M106 P5 T82 S150 L150 X150 H0 ; Exhaust fan ; Chamber Thermistor M308 S3 P"temp1" A"Chamber" Y"thermistor" T100000 B4725 C7.060000e-8 ; define chamber sensor ; Tools M563 P0 D0 H1 F0 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0CAnd the generated gcode and stl file (print time 9 min max):

Test.gcode

TEST.stl -

I did a esteps calibration today to rule out any extruder calibration issues.

Though Bondtech states it's not necessary, I wanted to be sure that esteps are spot on.

Turns out esteps are within 1-2% accuracy. So the extruder does work as intended.What else should I (double) check to rule out hardware issues? I mean, only 3 people so far in this thread confirmed PA issues out of 1000+(?) RRF users. That is peculiar.