electromagnet for tool dock

-

@dutti said in electromagnet for tool dock:

@fcwilt

the magnet is holding the tool directly. the tool has a small plate.. so in this case it should hold it while it´s not printing.I found this which maybe I can take for my own magnet system?

https://miscsolutions.wordpress.com/2020/06/06/improvements-to-the-hemera-tools/

Richard

I understand - it might be a good solution if the power required to hold the tool is not great.

Just be sure the magnet is rated for continuous power - many have severe duty cycle limits.

Let us know how it works.

Frederick

-

@dutti the holding force of that magnet is 20N (about 2kgf) using a 2mm counter plate. Do you need that much force? If you don't, then you may find that a 24V electromagnet powered from 12V is sufficient.

-

@dc42

Yes it's should be 2kg but if I really need them... I'm not sure, yet.

but if I really need them... I'm not sure, yet.

I'll power them from the mainboard duet 3 or expansion board.

I guess I can choose the voltage?

What would be the best option to connect it? To the fan outputs?

Richard -

@dutti said in electromagnet for tool dock:

What would be the best option to connect it? To the fan outputs?

Yes.

-

@dc42 Hello, Im experimented a simmilar soluction for dock tool, Im planning use the Electromagnet with a low PWM frecuency to avoid heating, I have a doubt.

In the post about connecting Fans said: "The polarity of the fans is important - don't connect them backwards." but the EM I have have the two cables blue without any polarity, only use 0.2 amps, so the pin could manage it, there is any risky to connect it to the FAN PWM pin? (in another post I wrote about my burned duet, maybe because of this)

-

@spirit-robotics

You need to add a diode across the magnet coil to prevent back emf spikes damaging the Duet board.A "flywheel diode" function, in other words; preferably something like a 1A fast recovery or schottky rectifier diode.

https://www.elprocus.com/freewheeling-or-flyback-diode-circuit-working-functions/The magnet coil polarity does not matter, but the diode polarity does - it should not be conducting with the normal supply polarity from the PSU or duet.

-

Thanks, now I know how I burned my duet, I was reading about it, you consider that this diode will work? it is rated 1amp

-

@spirit-robotics

A 1N4007 is better than nothing, but not ideal - they are a basic rectifier and react quite slowly to changes in polarity (the "reverse recovery" time).As the purpose of the diode is to protect from fast spikes, a fast recovery or schottky diode is much better.

A UF4007 (or other UF / UR 400x series) would be fine, likewise any 1A or higher schottky rectifier with a reasonable voltage rating.

Or use such as a 1N5819 or 1N5822 out of one of the cheap diode selection packs;

https://www.amazon.com/MICSPSF-Assortment-Rectifier-Recovery-Switching/dp/B08VDH8H35/ref=sr_1_6?keywords=1N5819&qid=1641541799&s=industrial&sr=1-6 -

@spirit-robotics which Duet do you have, and if it is a Duet 2, what board revision?

All duets except older Duet WiFi/Ethernet boards have flyback diodes built in to the fan outputs, so external ones are not needed. Duet 3/3 Mini boards also have flyback diodes built in to all heater outputs except heater 0.

If you do need a flyback diode, then as @rjenkinsgb says a fast recovery or Schottky diode is preferred.

-

@dc42 said in electromagnet for tool dock:

All duets except older Duet WiFi/Ethernet boards have flyback diodes built in to the fan outputs, so external ones are not needed.

That's fine, as long as the power to whatever is connected also comes from the same connector.

If by chance you use a separate positive supply and only switch the ground via the fan output, I'd consider an external flywheel diode to still be essential.

ps.

@dc42 - that rings a bell - another thread, someone having fan outputs fail, when using a separate positive feed?? I wonder if back EMF could be a cause? -

Also, on a related subject -

having a flywheel diode (or snubber etc. depending on the load) close to the load itself means the flywheel current or voltage spike is not passed along the connecting wires through the machine, which reduces the chance of interference with other signals.It's unrelated to damage to the electronics, but just good practice.

-

@dc42

Thinking further on the external supply situation:

You may need to update the board info and tell users not to use external supplies at a higher voltage than the onboard output is set to, on outputs with flywheel diodes.With a higher external supply to a load, the built-in flywheel diodes will presumably provide a direct path from that to the internal supply, when the output switch is off?

-

@dc42 My Duet are the lasted version v 1.04.

Output M115:

RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.3 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2021-06-15 21:45:03

About the diodes, they are always active? I supposed it is. In anycase how could be the circuit to put the diode? Thanks

-

@spirit-robotics the diode will be active if the fan voltage select jumper is installed. As @rjenkinsgb says, the external solenoid supply voltage must be no higher than the selected voltage on the fan jumper (normally VIN).

-

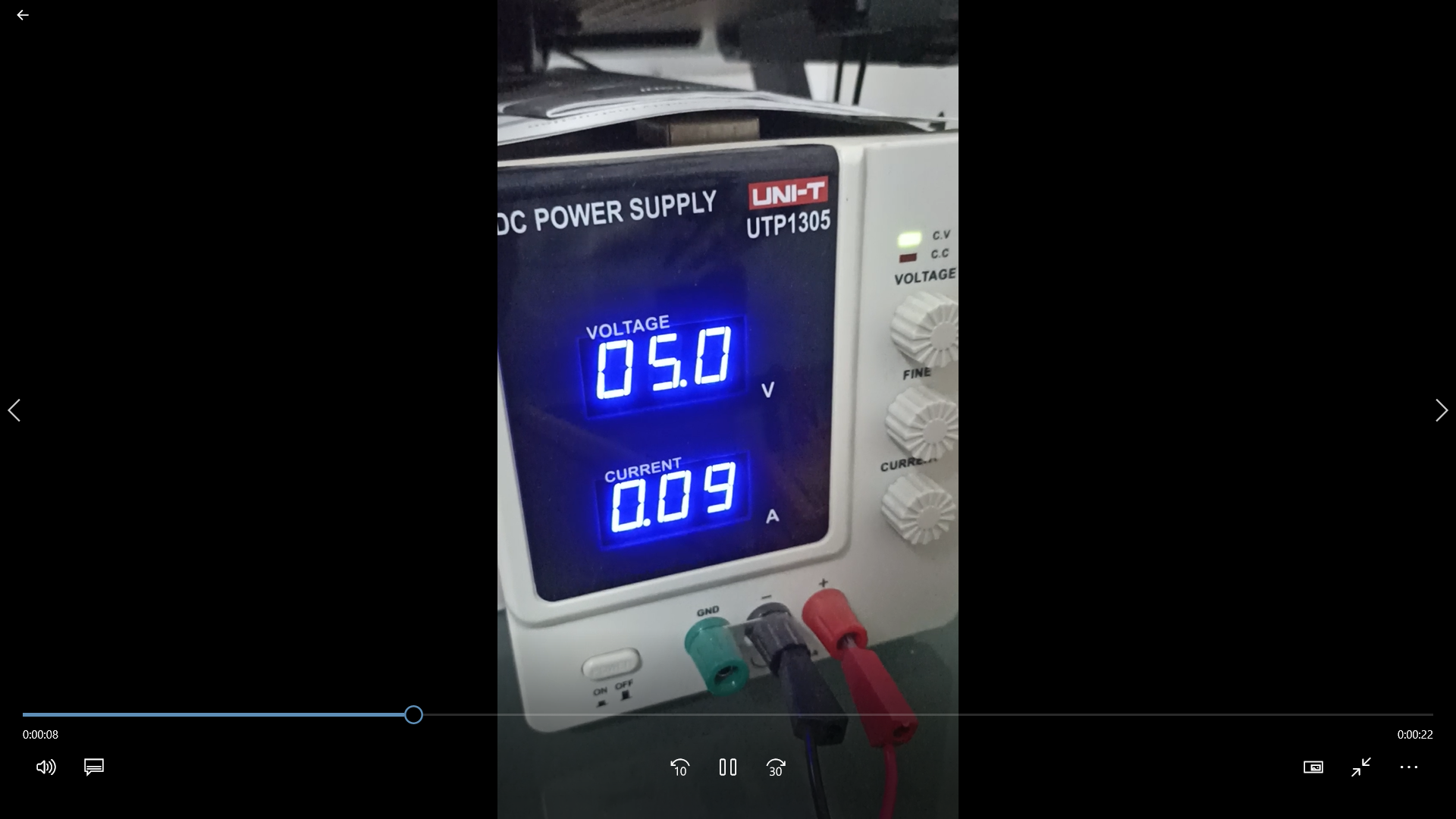

@rjenkinsgb Today I connect the board by USB and work fine, and connect a 5V FAN in the always ON fan and the fan work well.

However Im little worried if I try to connect the electromagnet, maybe the reason of the shortcut is different...

Just to understand, confirm ... in a board V1.04 I have the flyback diodes in place with the fans, so, in theory if I connect to the PWM Fan pin a small electromagent should be work?

The Electromagent, rated for 12V 0.2amps, but connected to the 5V pwn fan pin only need 0.09 amps ... could be work?

-

@spirit-robotics what position is the fan voltage section jumper in?

And what VIN voltage are you using?

-

@dc42 this is a test from my power supply, just to check.

I want to connect the electromagnet to a pwm fan pins at 5V, from the reading I understand that it will work because the board have the flyback diode and the current is small.

My idea is hold with the electromagnet my tool, I already tested the electromagnet with the DC power supply and the current is only 0.09 ampers, but still have enough force to hold the tool without getting hot the electromagnet.

Please let me know your recommendations.

-

This post is deleted! -

@spirit-robotics

Hi again

My solution is still working good. It's quiet simple.

I could share my solution...Cheers

Richard -

@gruna-studio Thanks, sure if you like, I already have my design, I want to hold a small iron plate attached to the tool with the electromagnet, no moving parts.

Im only double check how operate the electromagnet without burn again my board.

Best